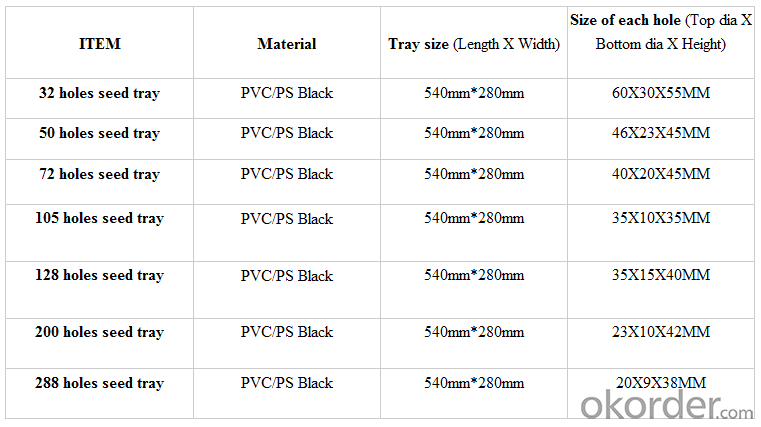

32/50/72/98/128/288 Cells Plastic Seeding Tray

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification of Plug Trays HIPS Made Plastic Plug Tray for Greenhouse (Growing and Seedling):

Features of Plug Trays HIPS Made Plastic Plug Tray for Greenhouse (Growing and Seedling):

· Material: HIPS

· Thickness: 0.5mm-1.5mm, Standard:1mm

· Weight: 80g(±5)g-230g(±5)g, Standard weight:155g(±5)g

· Size: length:490mm-540mm, width:190mm-345mm,depth:25mm-150mm

· Standard:540mmX280mm

· Cell count: 18-512

· Package: In Carton

· Warrenty: 8-10 times

Packaging & Delivery

Packing Detail: export standard carton or large bags

Delivery time: 4 million per momth after receipt of deposit

Advantage:

Waterproof, UV-resistant, extrusion-resistant

Easy carry for young seeding plant and grow

Service:

1. Quick, efficient and professional response within 24 hours, 14 hours online services

2. 10 years manufacturing and exporting experience in agriculture field.

3. Technical support and solution by chief engineer.

4. Strict quality control system & team, high reputation in the market.

5. Full range of irrigation products for choice

6. OEM/ODM services

7. Accept sample order before Mass Order

Picture of Plug Trays HIPS Made Plastic Plug Tray for Greenhouse (Growing and Seedling):

FAQ of Plug Trays HIPS Made Plastic Plug Tray for Greenhouse (Growing and Seedling):

Q: 1.How long is the production time?

A: Usually one to two weeks.

Q: 2.How is the seed tray being packaged?

A: They can be packaged in carton or pallets. Carton size is 1375px*725px*1250px.

Q:3.How many times can the seed tray be used?

A: Under the same environment, it is decided by the thickness. Usually 0.6mm thickness can be used for 1 or 2 times.

1.0 thickness can be used for 3-4 times. 1.5 thickness can be used for 8-10 times.

- Q:How are agricultural plastic products manufactured?

- Agricultural plastic products are typically manufactured through a process called extrusion. In this process, plastic resin is melted and forced through a die, resulting in the desired shape and size of the product. The extruded plastic is then cooled and cut into the required lengths or shapes. Various additives, such as UV stabilizers or colorants, can be incorporated into the plastic during the manufacturing process to enhance its properties.

- Q:Neka mi srbi odgovore.Tell me what plastic is

- very confusing matter. try searching using yahoo. this might help!

- Q:What are the benefits of using plastic grafting clips in plant propagation?

- Plastic grafting clips offer several benefits in plant propagation, including providing support to the graft union, ensuring proper alignment of the plant tissues, and preventing the movement of the graft during the healing process. These clips also create a stable environment for the newly grafted plants, reducing the risk of failure and increasing the success rate of grafting. Additionally, plastic grafting clips are easy to use, cost-effective, and do not cause damage to the plant tissues, making them a popular choice for propagators.

- Q:I'm currious if plastic can be renewed or are the ads at 3AM just selling hope

- Plastics can be made to look nice, but not be as strong as when new. Many plastic deteriorate in sunlight or over time. You cannot repair that.

- Q:How do nursery trays assist in the propagation of rare and endangered plant species?

- Nursery trays play a crucial role in the propagation of rare and endangered plant species by providing a controlled and optimal environment for their growth and development. These trays allow for the efficient and organized germination of seeds or cuttings, ensuring a higher success rate in establishing new plants. The trays also enable easy monitoring and management of the growing conditions, such as moisture levels and temperature, which are vital for the delicate needs of rare and endangered species. Overall, nursery trays help protect and conserve these plants by supporting their propagation and increasing their chances of survival.

- Q:What are the different types of plastic tunnels used in agriculture?

- There are several types of plastic tunnels used in agriculture, including low tunnels, high tunnels, and hoop houses. Low tunnels are smaller structures made with a layer of plastic covering a row of crops, providing protection from frost and pests. High tunnels are larger structures with a curved or arched shape, often used for growing crops year-round. They have sidewalls and roll-up or drop-down curtains for ventilation. Hoop houses are similar to high tunnels, but typically have a larger footprint and are used for commercial-scale production. They are constructed with hoops made of plastic or metal and covered with a layer of plastic for temperature and moisture control.

- Q:How are plastic greenhouse frames assembled?

- Plastic greenhouse frames are typically assembled by connecting the individual frame pieces together using connectors or clips. These connectors are designed to securely hold the frame pieces in place, creating a sturdy structure. The assembly process may involve sliding the frame pieces into the connectors or using screws or bolts to secure them. Additionally, some greenhouse frames may require additional bracing or support bars to ensure stability. Overall, the assembly process is relatively straightforward and can be completed by following the manufacturer's instructions.

- Q:How do you choose the right ground cover for a specific moisture requirement?

- To choose the right ground cover for a specific moisture requirement, it is important to consider a few factors. First, you need to assess the moisture level in the area where the ground cover will be planted. This can be done by observing the soil drainage and the amount of sunlight the area receives. Next, research different ground cover options that thrive in the specific moisture conditions you have identified. Some ground covers are better suited for dry conditions, while others prefer moist or even wet environments. Consider factors such as the plant's water needs, its ability to tolerate drought or excessive moisture, and its root system's ability to retain water. Additionally, take into account the aesthetics and functionality you desire from the ground cover. Some may prefer low-growing, spreading ground covers, while others may want taller, more ornamental options. Keep in mind the purpose of the ground cover, whether it is to prevent erosion, provide a lush appearance, or serve as a low-maintenance solution. Lastly, consult with local gardening experts or nurseries to get advice specific to your region's climate and soil conditions. They can provide valuable insights and recommend suitable ground covers that will thrive in your specific moisture requirements.

- Q:What types of plastic bags are used for flower packaging?

- The types of plastic bags commonly used for flower packaging include cellophane bags, polypropylene bags, and clear plastic sleeves.

- Q:What are the benefits of using plastic vineyard posts in grape cultivation?

- Plastic vineyard posts offer several benefits in grape cultivation. Firstly, they are lightweight and easy to handle, making installation and maintenance more convenient. Additionally, plastic posts are resistant to rot, decay, and insect damage, providing durability and longevity. They also have a smooth surface, reducing the risk of grapevine damage and disease transmission. Moreover, plastic vineyard posts offer flexibility, allowing for easier training and trellising of grapevines. Lastly, they are cost-effective compared to traditional wooden posts, making them a practical choice for vineyards.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

32/50/72/98/128/288 Cells Plastic Seeding Tray

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords