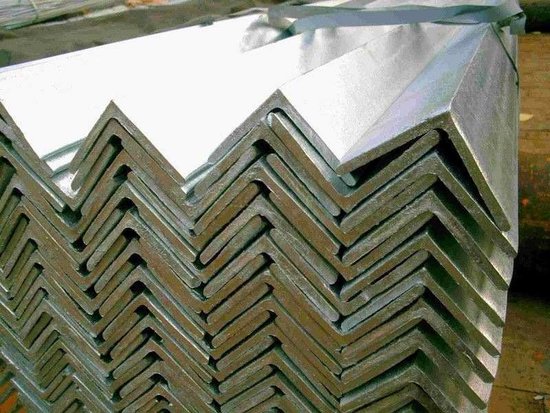

430 Stainless Steel Angles

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless Steel Angles

1.Grade: SS200,300,400 series

2.Size: 25×25×3 mm-100×100×10mm

3.Process: HRAP

4. Length: 2-6m

5. Shape: Equal

6. Delivery: within 20 days

7. MOQ: 1 ton

8. Certificate: ISO 9001:2008, SGS

9. Package:Standard Export Packing, or put into wooden boxes according to your

requirement

10. Application: Construction, Marine, Industry and so on

|

Name |

Stainless Steel Angles | ||||||

|

Standard |

ASTM A554, A312, A249, A269 and A270 | ||||||

|

Material Grade |

304,316,201,202, 316L,430 | ||||||

|

Length |

6m or as customers' request | ||||||

|

Tolerance |

a) thickness: +/-0. 15mm | ||||||

|

| |||||||

|

b) Length:+/-4. 5mm - 0mm | |||||||

|

Surface |

180G, 320G, 400G Satin / Hairline(Matt Finish, Brush, Dull Finish) 400G, 500G, 600G or 800G Mirror finish | ||||||

|

Application |

Decoration construction, upholstery, industry instruments | ||||||

|

Test |

Squash test, Extended test, Water pressure test, Crystal rot test, Heat treatment, NDT | ||||||

|

Chemical Composition of Material |

Composition

Material |

201 |

202 |

304 |

316L |

430 | |

|

C |

≤0.15 |

≤0.15 |

≤0.08 |

≤0.08 |

≤0.12 | ||

|

Si |

≤1.00 |

≤1.00 |

≤1.00 |

≤1.00 |

≤1.00 | ||

|

Mn |

5.5-7.5 |

7.5-10 |

≤2.00 |

≤2.00 |

≤1.00 | ||

|

P |

≤0.06 |

≤0.06 |

≤0.045 |

≤0.045 |

≤0.040 | ||

|

S |

≤0.03 |

≤0.03 |

≤0.030 |

≤0.030 |

≤0.030 | ||

|

Cr |

16-18 |

17-19 |

18-20 |

16-18 |

16-18 | ||

|

Ni |

3.5-5.5 |

4-6 |

8-10.5 |

10-14 |

| ||

|

Mo |

|

|

|

2.0-3.0 |

| ||

|

Mechanical Property |

Material Item |

201 |

202 |

304 |

316L | ||

|

Tensile Strength |

≥535 |

≥520 |

≥520 |

≥520 | |||

|

Yield Strength |

≥245 |

≥205 |

≥205 |

≥205 | |||

|

Extension |

≥30% |

≥30% |

≥35% |

≥35% | |||

|

Hardness (HV) |

<253 |

<253 |

<200 |

<200 | |||

- Q:What are the typical tolerances for stainless steel angles?

- The tolerances for stainless steel angles can vary depending on the application requirements and manufacturing process. However, there are industry standards for tolerances in the production of stainless steel angles that are generally accepted. Regarding dimensional tolerances, the width or leg length of a stainless steel angle typically has a tolerance of ± 1/16 inch. This means that the actual width or leg length can deviate by up to 1/16 inch from the specified dimension. Similarly, the thickness of the angle usually has a tolerance of ± 1/8 inch. For angular tolerances, the straightness of a stainless steel angle is typically specified as 1/8 inch per foot. This means that for every foot of the angle's length, it can deviate from being perfectly straight by up to 1/8 inch. Surface finish is also an important aspect of stainless steel angles, and the tolerance for surface roughness or smoothness can vary depending on the desired finish. Common finishes for stainless steel angles include mill finish, brushed finish, and polished finish. Each finish has specific tolerance requirements to achieve the desired appearance and functionality. It's important to note that these tolerances serve as general guidelines and can vary depending on the specific standards and requirements established by the manufacturer or customer. Therefore, consulting the manufacturer or relevant industry standards is always recommended to determine the precise tolerances for a particular stainless steel angle application.

- Q:How is a stainless steel angle manufactured?

- A stainless steel angle is typically manufactured through a process known as hot rolling, where a stainless steel billet is heated to high temperatures and then passed through a series of rolling mills to shape it into the desired angle profile. This process helps in achieving the required dimensions, smooth surface finish, and improved mechanical properties of the stainless steel angle.

- Q:How do you determine the torsional strength of a stainless steel angle?

- To determine the torsional strength of a stainless steel angle, several factors need to be considered. Firstly, it is important to understand that torsional strength refers to the ability of a material to resist twisting or rotational forces. In the case of a stainless steel angle, torsional strength is a measure of its resistance to deformation or failure when subjected to torsional loads. One way to determine the torsional strength is by conducting a torsion test. This test involves applying a twisting force to the stainless steel angle until it reaches its maximum torsional strength or failure point. The test is typically performed using a torsion testing machine that applies a controlled torque to the angle. During the torsion test, various parameters are measured, including the angle of twist, torque, and torsional stress. These parameters can be used to calculate the torsional strength of the stainless steel angle. The torsional strength is usually expressed in terms of torque per unit length or torque per unit area. It is worth noting that the torsional strength of a stainless steel angle can depend on several factors, such as the alloy composition, heat treatment, and manufacturing process. Therefore, it is essential to ensure that the test specimens are representative of the actual angle being used in the application. In addition to torsion testing, other methods such as finite element analysis (FEA) can also be employed to determine the torsional strength of a stainless steel angle. FEA uses computer modeling and simulation techniques to analyze the behavior of the angle under torsional loads. This approach allows for a more detailed understanding of the angle's torsional strength and can help optimize its design for specific applications. In conclusion, determining the torsional strength of a stainless steel angle involves conducting torsion tests or utilizing computational methods such as FEA. These methods provide valuable information about the angle's resistance to twisting forces and help ensure its suitability for various engineering applications.

- Q:How do stainless steel angles perform in humid environments?

- Stainless steel angles perform exceptionally well in humid environments due to their inherent corrosion resistance properties. The chromium content in stainless steel forms a thin, protective oxide layer on the surface, which prevents moisture from penetrating and causing rust or corrosion. This makes stainless steel angles highly durable and reliable, even in high humidity conditions.

- Q:Can stainless steel angles be bent or twisted?

- Yes, stainless steel angles can be bent or twisted to a certain extent. However, due to their strong and rigid nature, they may require specialized equipment and techniques for the bending or twisting process.

- Q:304 stainless steel 32mm in diameter and 3mm in thickness. How much pressure can one metre withstand? How can I calculate the pressure of a pipe?

- Depends on the specific specifications, the prices of different specifications201 of stainless steel is now considered as ordinary material, without magnetic or nickel. If you want high, you should use 304 stainless steel, 6.5 yuan more than 201 yuan a kilogram.

- Q:What are the standard finishes available for stainless steel angles?

- The standard finishes available for stainless steel angles include mill finish, brushed finish, and polished finish.

- Q:Can stainless steel angles be used in outdoor environments?

- Yes, stainless steel angles can be used in outdoor environments. Stainless steel is highly resistant to corrosion and rust, making it an ideal material for outdoor applications. It can withstand exposure to moisture, extreme temperatures, and various weather conditions without deteriorating or losing its strength. Stainless steel angles are commonly used in outdoor structures such as fences, handrails, guardrails, and support beams where durability and resistance to environmental elements are crucial. Additionally, stainless steel has an attractive appearance and can maintain its polished finish even in outdoor settings, further enhancing its suitability for outdoor use.

- Q:How do you calculate the section modulus for a slotted stainless steel angle?

- To calculate the section modulus for a slotted stainless steel angle, you would need to first determine the moment of inertia of the section. The moment of inertia is a measure of an object's resistance to changes in its rotation, and it can be calculated using the dimensions and shape of the object. For a slotted stainless steel angle, you would need to know the dimensions of the angle, including the length of each leg and the thickness of the angle. Once you have these dimensions, you can use the appropriate formula to calculate the moment of inertia for the section. The moment of inertia is calculated differently depending on the shape of the section. For a slotted angle, the moment of inertia can be calculated as the sum of the individual moment of inertia for each part of the section. This means that you would need to calculate the moment of inertia for each leg of the angle and the slot separately, and then add them together. Once you have calculated the moment of inertia for the slotted stainless steel angle, you can use this value to calculate the section modulus. The section modulus is a measure of the resistance of a section to bending and is calculated by dividing the moment of inertia by the distance from the neutral axis to the outermost fiber of the section. The section modulus is an important parameter in structural engineering as it helps determine the strength and stiffness of a section. It is often used in the design of beams and other structural members to ensure that they can withstand the loads they will be subjected to. In summary, to calculate the section modulus for a slotted stainless steel angle, you would need to calculate the moment of inertia for each part of the section, including the legs and the slot, and then sum them together. This moment of inertia can then be used to calculate the section modulus, which is an important parameter in structural engineering.

- Q:Are stainless steel angles resistant to phosphoric acid?

- Yes, stainless steel angles are generally resistant to phosphoric acid. Stainless steel is known for its corrosion resistance properties, and it is particularly resistant to most acids, including phosphoric acid. However, the level of resistance can vary depending on the grade of stainless steel and the concentration and temperature of the phosphoric acid. In general, stainless steel angles made from austenitic stainless steel grades such as 304 or 316 are highly resistant to phosphoric acid, even at higher concentrations and temperatures. However, it is always recommended to consult with a materials specialist or refer to corrosion resistance charts to ensure the appropriate grade of stainless steel is used for specific applications involving phosphoric acid.

1. Manufacturer Overview |

|

|---|---|

| Location | Jiangsu, China |

| Year Established | 2010 |

| Annual Output Value | above US$3 million |

| Main Markets | East Asia, Middle East. |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 50% |

| No.of Employees in Trade Department | above 10 people |

| Language Spoken: | English, Chinese |

| b)Factory Information | |

| Factory Size: | about 50000 square meter |

| No. of Production Lines | above 3 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

430 Stainless Steel Angles

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords