720 * 750 * 70 mm CCOLU 1560 Economical Plastic Formwork for Rectangle / Square Column

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 500 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

720 * 750 * 70 mm CCOLU 1560 Economical Plastic Formwork for Rectangle / Square Column

1. Description:

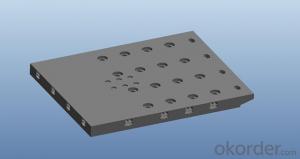

Column panel is a modular shuttering panel, made of high impact resistant PP plastic, for reinforced concrete columns, pile caps and walls. The panels are engineered to interconnect orthogonally in different positions, creating a “star”-shaped formwork of variable size.

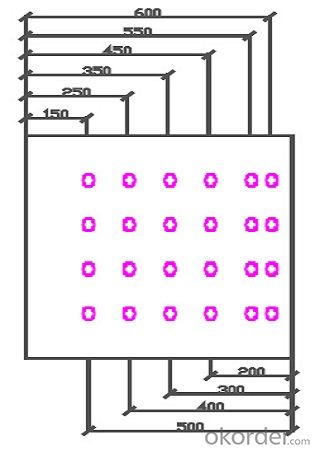

The column panels are interconnected using the standard nylon locking handles. Each panel will require 9 handles. The forming face has 6 parallel rows of fixing holes to allow the orthogonal connection of the panels in a “star” shape. The rows are placed at a distance of 100/50 mm the one from the other, allowing the forming of square and/or rectangular columns with side of 150 to 600 mm.

There is a series of holes in the middle of the panels for the passage of tie rods. The position of the holes is asymmetric to avoid conflict between crossing tie rods. All unused holes are closed with plugs.

A column 3m height is formed with 16x column panels, 8 x tie rods, 16 x washers, 144 x handles, 4 vertical steel reinforcement bars.

Showing of different size of column.

2. Advantages:

Easy Set Up

Different size of panels can be firmly locked by simply turn the special handles to 90 degree. The panels have rib on the back, which makes the system need not traditional wood blocks and nails. The panels have holes to fit tie rod, guarantee the strength of the whole system.

Strength

The material of modular formwork is PC ABS mixed with special glass fibers which enable panels to hold high pressures.

Environment Friendly

The system need not cut and nail due to the variety size, and nearly need no wood, the material can be recycled after broken, will not pollute the environment.

Consequent

Concrete does not stick to plastic, thus the panels need no oil before using, and can be cleaned simply by water. The surface of the wall which built by modular formwork is smooth, can be left without rework.

- Q:Will the plastic building template on the builders really do not use the price is how much price

- Easy to use, heat insulation. A lot of building materials market there ah, to see what you want the model, the price range,

- Q:Is there a kitchen toilet to seal the water pipe plastic template? Where to sell?

- The general building materials market have to sell, I hope my answer can help you ~

- Q:Who used plastic building templates? How is the effect? What are the advantages and disadvantages?

- Plastic building template is an energy-saving and green products, is following the wood template, the combination of steel formwork, bamboo glued template, all the steel template after another new generation of products. Can completely replace the traditional steel formwork, wood template, square wood, energy saving and environmental protection, amortization cost is low.

- Q:Want to purchase a number of building templates and found a new plastic building template, do not know how the quality?

- To be honest, not very good. The Temporary use can be

- Q:Europe and the United States national construction template is made of plastic or wood

- With plastic construction, then, is the most solid touch on the back, Europe and the United States part of the country after the earthquake so the use of wood plus wire

- Q:I heard that there are building aluminum template and plastic template it? Which is better?

- Wood-plastic building templates in the construction works more useful, more affordable, more convenient.

- Q:Why the floor is not plastic building materials square wood and template

- Is the plastic strong? The environment on the site you know, throw off how to do, have to find strong and durable.

- Q:Does the building plastic template use it? How's the effect? Can I use 30 to 50 times? Can the fire protection requirements of the steel plate on the cast-in-place plate be achieved?

- The reason why the use of the template is to use the template template is the accuracy of the template, that is, after the mold can be set to ensure that the finished product finished shape regular, flush. While the plastic film version is not damaged, the completion can achieve this requirement. But the crux of the problem is that the biggest weakness of the plastic film is too brittle. Those who have done the work know that when the demolition of the template, the workers removed the template directly down to throw. And this throw to lead to the plastic film version of the broken, it is very difficult to film in the film. This is also the reason why the plastic film from the interview more than 10 years can not always develop the root causes. And then plastic film board in the mold when it is very strenuous, must drill with a drill, or can not die, not convenient construction. This is also a plastic film version can not become a mainstream template and a fatal weakness. The third weakness is its flammability. Construction site of the steel connections are required welding, welding flowers gradually to the plastic film board, at least in its surface to form a deep pit (or even lead to fire), a direct impact on the finished product surface finish and flatness.

- Q:How does the concrete on the plastic template remove (already glued to the concrete)

- Water, washed with water, rubbing with things, spend time slowly removed

- Q:Why is the building template made 1830mm * 915mm and not made 2000mm * 1000mm it?

- You can do that kind of ah! Raw materials are not easy to find

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

720 * 750 * 70 mm CCOLU 1560 Economical Plastic Formwork for Rectangle / Square Column

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 500 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords