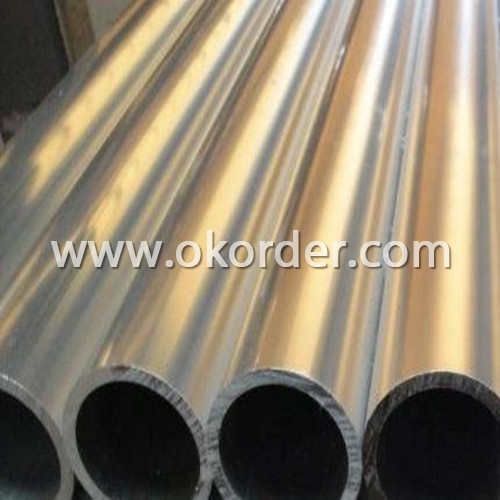

Aluminium Pipes 6XXX

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Specifications of Aluminum Pipes 6XXX

Alloy Number | AA 6XXX |

Temper | O, F,H112,T4,T5,T6,T3,T8 |

Thickness | 0.5-50mm |

Length | <=13m |

Diameter | Outer: 9-500mm |

Standard | GB/5237.2-2004, ASTM, ISO, EU standard |

Special specification is available on customers' requirements.

2. Usage/Applications of Aluminum Pipes 6XXX

Aluminum pipes are widely used for building construction, housing decorations, industry & agriculture & architecture usage etc.

3. Packaging & Delivery of Aluminum Pipes 6XXX

Packaging: Seaworthy package, bubble plastic bag inside, anti-moisture paper wrapped outside, covered with cartons, on wooden pallets, in containers. Pallet weight: Max. 2.30 tons.

Shipment: the goods will be delivered in 30 days after getting the buyer's payment.

4. Production Flow of Aluminum Pipes 6XXX

Casting--extruding--cutting--coating—further processing--packing

- Q:I am now a lot of goods, some can be folded, and some directly broken, and this is how it happened?

- As a rule, T5 can not be bent. If you want to fold it, you need to heat it and then fold it.O or H status can be bent

- Q:What is the average lifespan of aluminum pipes?

- The average lifespan of aluminum pipes can vary depending on various factors such as the quality of the material, the environment in which they are used, and the maintenance and care they receive. Generally, aluminum pipes have a relatively long lifespan and can last for several decades. With proper installation, regular inspections, and timely repairs, aluminum pipes can serve their intended purpose for 30 to 50 years or even longer. However, it is important to note that external factors such as corrosion, exposure to harsh chemicals, or extreme temperature variations can significantly impact the lifespan of aluminum pipes. Therefore, regular maintenance and periodic evaluations are essential to ensure the longevity and performance of aluminum pipes.

- Q:What is the tensile strength of the 6063T5 aluminum tube and what is the elongation rate?

- The tensile strength of 6063T4 aluminium tubes is about 150. The elongation rate is about 10%. T6's around 230. The elongation rate is about 8%As it were, you can Q me: 88099379 (Shanghai Xuan Sheng)

- Q:How can the air conditioning aluminum pipe be welded?

- Air conditioning tubes can use oxygen or gas welding, aluminum welding wire with low temperature, the low temperature aluminum wire 4047 Al Si wire 580 degrees temperature, the welding auxiliary welding powder welding, there is a 430 degree temperature WEWELDING Q303 welding wire.Air conditioning aluminum tube can also be welded by aluminum argon arc welding machine, with 5056 aluminum magnesium welding wire argon arc welding.

- Q:Are aluminum pipes resistant to chemicals?

- Yes, aluminum pipes are generally resistant to many chemicals due to their corrosion resistance properties. However, certain highly alkaline or acidic substances may still cause damage or corrosion to aluminum pipes over time.

- Q:What is the extrusion process of aluminium tube?

- Process flow is:Billet heating, hot extrusion, cutting, boring, wagon, wool two heating, extrusion, tension or straightening roller leveler, cutting chuck - intermediate annealing, corrosion, inspection, repair, scraped the cold rolling, annealing, quenching, stretching, heading to the whole diameter, straightening, cutting and finished product sampling artificial aging, annealing, inspection and acceptance, oiling and packing

- Q:Can aluminum pipes withstand high wind loads?

- Indeed, high wind loads can be withstood by aluminum pipes. Renowned for its strength-to-weight ratio, aluminum proves itself as an optimal material for diverse uses, encompassing structural components. Frequently employed in construction, especially for outdoor structures like flagpoles, antennas, and support frames, aluminum pipes exhibit remarkable resistance against wind loads owing to their impressive tensile strength and corrosion resistance. Moreover, aluminum pipes can be custom-designed and manufactured to fulfill precise load prerequisites, guaranteeing their capacity to endure powerful winds.

- Q:What is the typical wall thickness of aluminum pipes?

- The typical wall thickness of aluminum pipes can vary depending on the specific application and industry requirements. However, common wall thicknesses for aluminum pipes range from 0.065 inches to 0.250 inches.

- Q:The air conditioner is broken in the middle of the aluminum tube. How can I weld it?

- There are two kinds of welding methods for aluminum pipe.Method: gas, liquefied gas welding gun with WE-Q303 low temperature aluminum wire.Method two: AC argon arc welding, argon arc welding with aluminum argon arc welding machine.

- Q:Are aluminum pipes suitable for automotive exhaust systems?

- Automotive exhaust systems can indeed utilize aluminum pipes. Aluminum, being both lightweight and durable, possesses numerous advantages for exhaust systems. To begin with, aluminum pipes exhibit resistance to corrosion, a critical characteristic for an automotive exhaust system exposed to heat, moisture, and various chemicals. This resistance to corrosion aids in extending the lifespan of the exhaust system and ensures its proper functionality over an extended period. Moreover, aluminum pipes possess exceptional heat dissipation properties. Thanks to aluminum's high thermal conductivity, it can rapidly dissipate the heat generated by exhaust gases, thereby preventing overheating and potential harm to other vehicle components. This becomes especially crucial in high-performance vehicles, where exhaust temperatures can rise significantly. Furthermore, aluminum pipes are relatively easy to manipulate and can be shaped and sized in various ways, making them versatile for different vehicle applications. Their lightweight nature also contributes to enhanced fuel efficiency and reduced overall vehicle weight, both of which can have a positive impact on performance. However, it is important to note that aluminum pipes may not be suitable for every automotive exhaust system. In situations where extreme temperatures or excessive vibrations are expected, alternative materials like stainless steel or titanium may be more appropriate. Nevertheless, for most standard to moderately high-performance vehicles, aluminum pipes represent a suitable and cost-effective choice for automotive exhaust systems.

1. Manufacturer Overview |

|

|---|---|

| Location | Guangdong, China |

| Year Established | 2004 |

| Annual Output Value | Above US$50 Million |

| Main Markets | Mid East;Eastern Europe;North America |

| Company Certifications | ISO 9001:2000;ISO 14001:2004;OHSAS 18001 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 30%-50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b)Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Aluminium Pipes 6XXX

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords