Aluminum Alloy Wheel Hub for Automobile

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 800 PCS

- Supply Capability:

- 28000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

OKorder is offering high quality Aluminum Alloy Automotive Wheel Hubs at great prices with worldwide shipping. Our supplier is a world-class manufacturer of lost wax castings in aluminum, and one of the largest casting production bases in China. We have supplied more than 8000 tons of wheel hubs annually to European, North American and Asian markets. Additional OEM casting and forging services are available according to customer requirements.

The intended use of Aluminum Alloy Automotive Wheel Hubs

Our Aluminum Alloy Automotive Wheel Hubs are ideal for:

Automotive applications

The advantage of Aluminum Alloy Automotive Wheel Hubs

Not only are OKorder's Aluminum Alloy Automotive Wheel Hubs of the highest quality and reliability, they are also lightweight, durable and fuel efficient. We are able to quickly ship orders within 20 days of receiving a deposit or original L/C. All products are shipped with ISO, SGS, BV, and CIQ certification as well as ASTM, AISI, DIN, BS and JIS standards.

Main features of Aluminum Alloy Automotive Wheel Hubs

Additional OEM casting and forging services available

Shipped within 20 Days

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How are our Aluminum Alloy Automotive Wheel Hubs manufactured?

A: All of our products are lost wax castings, poured in aluminum to the highest tolerances.

Images

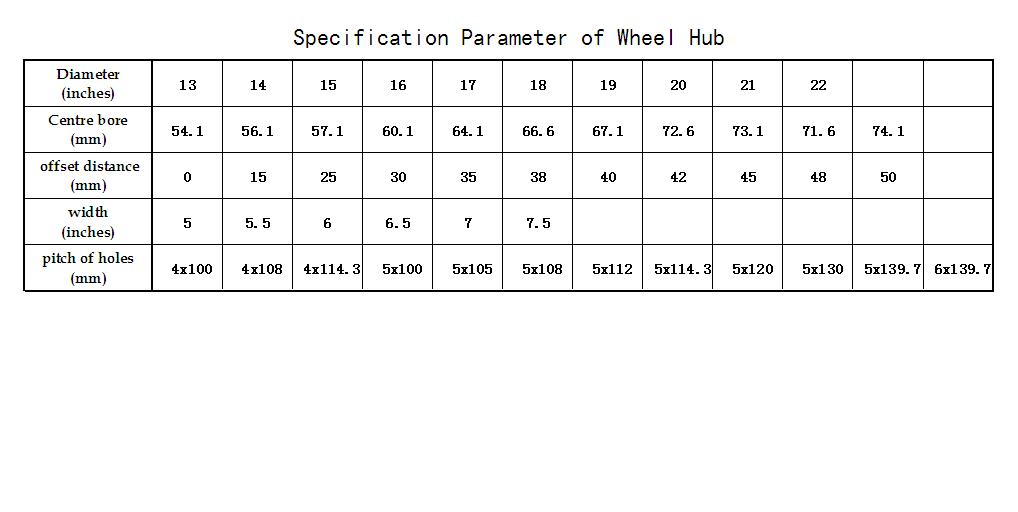

Aluminum Alloy Wheel Hub Specification

- Q:There is no description of the Toyota car parts coding book

- Is there a service station?

- Q:Who knows the most detailed structure of the car? Is it all the names of all parts of the car?

- Car parts of the tens of millions, not a few words can be clear, most people know about a good, chassis chassis, engine, gearbox, power system, exhaust system, and so on, and then subdivided, such as Car cover sub-roof, front and rear cover, front and rear bumper, front and rear sides of a total of four fender, four doors

- Q:What is the order of the hand-wave start and stop parts? The Clutch, brake, brake, ignition, etc. The correct operation sequence of these parts? Start and

- Stop the order: After stopping, press the brake and clutch pedal → Hanging neutral → Release the clutch pedal → Handbrake → release the brake pedal → turn off all electrical appliances (air conditioning, radio, etc.) → raise the window → turn off the key → Lock the car.

- Q:In the car 4S shop maintenance parts will not be replaced? anxious!

- Under normal circumstances will not happen this kind of thing, most of the shop will be managed, it is impossible to casually replace the accessories, but if the company management chaos, then it is hard to say, look at your feelings. Also, usually, the owner is looking at the side, would like to change is not so easy. Moreover, the competition is now very intense, generally not hit their own brand. Go to 4S is not assured, good service? But the price is really expensive ah.

- Q:The auto parts number queries which is better

- LOUZHU direct global auto parts OE information network, free registration of users, which is Teduo grams of the query system, you can query the global brand car, very easy to use.

- Q:Is the coating of the car body the same as the coating process for the auto parts? Quality control in the body coating on the more important, or parts, there is a difference?

- For quality control, it is important, and the focus will be different.

- Q:What is the number of forklift body parts called

- Forklift site where there is a rotating stick, called the drive shaft, in front of a back, called the front drive shaft and rear drive shaft. Forklift four tires in the middle of each have a large iron ball, called "bridge", front axle and rear axle, drive axle. Forklift behind the water tank there is a full iron plate (mesh), called "water tank radiator." The forklift lifts the arm or bucket to stretch it, the sparkling steel bar, called the piston rod, can also be called telescopic steel. The outer side of the piston rod, called the cylinder, the hydraulic cylinder. There is a general piston rod above a small iron bar, called the bucket pointer, and some forklifts did not.

- Q:What is the meaning of rps in car parts?

- Reference Point System

- Q:Parts refers to shovels, wrenches, pliers, toolbox, and body parts of different colors. If the individual color is afraid of the body of the paint was dissolved glue. And water will also be dissolved by glue.

- Install the paint together and then paint the pen

- Q:(Before, after, after)

- The beams are also used to install engines, transmissions, body and fuel tanks. In order to adapt to different models, beams are arranged in a variety of types, such as in order to improve the torsional rigidity of the frame using X-type layout of the beam. Side beam structure is simple, low process requirements, easy to manufacture, widely used. But because of the thick beam through the whole car, affecting the vehicle layout and space utilization, the cross section of the beam height to increase the distance from the distance, the passengers on and off the car is not convenient, the other weight is also large, vehicle driving economy deterioration The These shortcomings on the small bus, the car is a disadvantage, for off-road vehicles may be the advantage, because the off-road vehicles require a strong pass, driving rugged road to have a certain large ground clearance, and very bumpy road will make the body Drifting, only with a rigid frame of the load-bearing body structure to withstand this impact. So off-road vehicles commonly used non-load-bearing body.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminum Alloy Wheel Hub for Automobile

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 800 PCS

- Supply Capability:

- 28000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords