Building tunnel formwork system

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

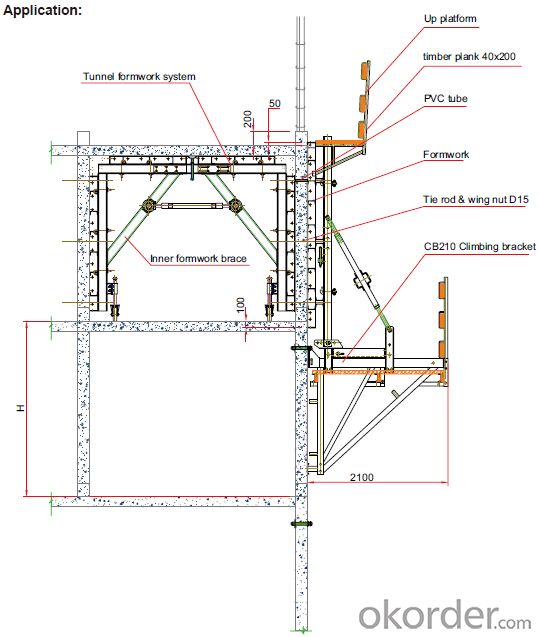

Building Tunnel Formwork:

A compositional steel formwork system mainly used in the building which has regular structure

without beams, the excellent formwork system can make the integral pouring for the wall & slab

easily achieved.

Characteristics:

◆ High stiffness, make perfect shape for concrete.

◆ Easy operation, save labor and force.

◆ Fast forming, repeatedly turnover.

- Q:What is the role of the tunnel formwork trolley? What is the use of template trolley?

- The use of full circle wear line; side and roof arch lining are most commonly used, two concrete lining construction commonly used in highway, railway tunnel and underground cavern.

- Q:The tunnel lining is wood, how should support?

- Two concrete tunnel lining, template is used according to the size and shape of the tunnel design custom-made, I-beam welded frame, welded steel plate, known as the "two trolley liner" (hydraulic jack lifting and installation of steel wheel moving on the rail), is generally the length of 9~12m, concrete pouring pump concrete.

- Q:When the tunnel fight, there is no provision to fight how many meters left, only by one of the construction

- Electric heating plate can be used for bonding or cold bonding (rubber water seal) or welding (plastic water stop) method, such as user connections are difficult, I can send technical personnel on-site guidance.

- Q:How the arch of the tunnel concrete pouring up, how to support before pouring, using I-beam is directly support the earth?

- Small pipe or large, medium pipe shed is the advanced support for the broken rock area or into, out of the hole, of course, grouting, grouting without losing the significance of the implementation.

- Q:Main diseases and prevention of tunnel

- Tunnel shotcretePhenomenon: the concrete spray layer and the rock surface is not bonded, concrete spray layer between the bond is not good.Cause analysis: the loose rock not clear spray surface; shotcreted rock debris is not scum washing or flushing thoroughly with wind pressure, water pressure; surface by spraying water, water, water concentration of untreated concrete spraying interval; before a layer of spray surface without wind, water washing scum. The air pressure is inconsistent with the spray distance.Preventive measures: remove the loose rock, clear surface by spraying of water, slag floating debris; water, concentrated water point of the surface by spraying with gouge, guide the drainage treatment of buried pipe; sprayed concrete before spray test, to determine the wind and spray distance coordination relationship between.

- Q:There are no recycling tunnel templates

- If it is a tunnel two lining car template, and the use of the tunnel after the car can continue to use the value of such a tunnel lining car basically has a market of two, but also to be recycled. The specific recovery and continue to use, mainly to see the two lining of the tunnel and the old and new without modification.

- Q:What is the role of the grid steel frame and steel mesh in the power tunnel

- Advanced small pipe grouting small catheter with a diameter of 32-50mm steel pipe, the pipe tip and tube holes for special processing. The first row with drill drilling pipe. Row spacing is 30cm, fan shape, elevation of 5 degrees to about 8 degrees. The length is 2.25m, a single fluid grouting (cement) or double grout (cement water glass slurry). Adjust the grouting pressure according to the soil.

- Q:How many meters can be poured in the first floor of the 2 level of the surrounding rock of the railway tunnel?

- And these kinds of excavation methods need to determine the number of excavated meters according to the grade of surrounding rock. Tunnel invert and floor is completed after the initial support (that is, shotcrete, a layer of concrete, in the excavation of rock on some hard rock without vertical spray arch thin, weak surrounding rock shall be sprayed on the vertical arch thickness in this special project map will show) for pouring 2 reinforced concrete lining when left in general is 6~12 meters

- Q:Tunnel construction procedure A cycle of steps

- The construction and tunnel portalWith the support from top to bottom layered excavation hole slopes, and Myeong Dong, and permanent and temporary outside waterproof and drainage should be first, make the surface smooth water, avoid surface water erosion on slope. Is necessary to take artificial slope repair, prevent overbreak, reduce disturbance to the adjacent area; excavation slope will be used in the design of the door, reducing exposure to rock weathering, support to follow, within the jurisdiction for high slopes, if not timely, can not guarantee the safety, and many of the human condition waste,The lining must check and recheck side wall foundation Myeongdong geologic condition and the bearing capacity of the foundation, to meet the design requirements, measurement lofting, frame formwork support, assembling reinforcement, inside and outside the template, the first wall arch integral casting lining concrete, mixing pump into the mold, insert type vibrator with attached type vibrator tamping compaction device.For the construction of portal portal with cut bamboo, also for cutting bamboo cut, plane mounted wooden formwork according to the slope, the slope angle and side end die die fixed into a whole.The waterproof layer and backfillingAfter the completion of open cut tunnel lining strength up to 50% can be removed outside the mold, with a waterproof layer, each layer of backfill should be symmetrical on both sides of the height difference is not greater than 30cm, not more than 50cm, after re stratified backfill to the vault, filled to the completion of a good surface aquifuge.

- Q:Who can give me detailed tunnel construction process

- On the inner side wall heading section is advanced, the footage was 0.7m immediately on the rock surface at the beginning of the spray, install the first layer of rock along Phi 8 steel mesh, and connected into a whole, set up active and temporary supporting steel arch, and the arch and a connected whole Phi 25 steel, drilling into the phi 25 hollow bolt and grouting, the installation of second layer steel mesh shotcrete layer to design contour line, pay attention to every compact trusses on the back of the footage, about 5~10m after the excavation under the heading section, and the lateral wall of drift can also present a ring section excavation footage was about 20 ~ 35m, support the arch excavation core soil upper arc heading, 3 ~ 5 after excavation footage and central support, under the section of tunnel bottom and the lower end of the previous about heading completely combined with closed loop, is divided into seven excavation, all operations must strictly follow the open Step by step, must be two inside the wall first, follow up the process step by step process. At the same time there must be monitoring data as the basis, redistribution of stress or conversion, will increase the support displacement, and strata subsidence and deformation, should strengthen the monitoring capacity before and after removal of the tunnel deformation and supporting force measurement,

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Building tunnel formwork system

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Hot Searches

Related keywords