Empty Aerosol Spray Can For Hair Care, 57mm

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 pc

- Supply Capability:

- 30000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief description

Content: hair spray

Size: 57X260mm

Printing: CMYK printing as Per Customer Design

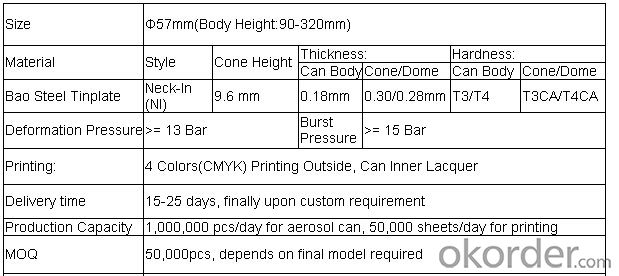

2.Detailed Specification

3.Usage:

suitable for insecticide, air freshener, body spray, lighter refill, car care etc

4.Packing

5.Appearance Specifications

Diameter(mm) | Type | Straight(mm) |

45mm | Necked-in | 80-220 |

52mm | Necked-in | 80-300 |

52mm | Straight | 76-200 |

57mm | Necked-in | 90-240 |

60mm | Necked-in | 90-240 |

60mm | Straight | 80-300 |

65mm | Necked-in | 80-240 |

65mm | Straight | 80-240 |

6.FAQ

1. Delivery Time:15-25 days, time can be shorten upon customer’s situation

2. Productivity:1,000,000 Cans/Day; 500,000 Printing Sheets/Day

3. MOQ:50,000pcs, but finally upon your size

4. Payment Term: 30% TT in advance, 70% balance against BL copy; 100% by LC at sight

- Q:What is the global demand for tinplate?

- The global demand for tinplate is significant and steadily increasing. Tinplate is widely used in the packaging industry, particularly for food and beverage cans, due to its excellent corrosion resistance and ability to maintain product freshness. Additionally, the growing popularity of canned food, beverages, and other consumer goods across various regions has further fueled the demand for tinplate worldwide.

- Q:What are the common misconceptions about tinplate packaging?

- One common misconception about tinplate packaging is that it is easily dented or damaged. In reality, tinplate is quite durable and can withstand rough handling without losing its structural integrity. Another misconception is that tinplate packaging is not environmentally friendly. However, tinplate is highly recyclable and can be reused multiple times, making it a sustainable packaging option.

- Q:What are the advantages of using tinplate for signage?

- There are several advantages of using tinplate for signage. Firstly, tinplate is highly durable and long-lasting, making it ideal for outdoor signage that needs to withstand various weather conditions. Additionally, tinplate is resistant to corrosion, reducing the risk of the signage deteriorating over time. Furthermore, tinplate can be easily shaped and molded into various designs, allowing for creative and eye-catching signage. Lastly, tinplate is cost-effective compared to other materials used for signage, making it an affordable option for businesses.

- Q:How does tinplate packaging contribute to product protection during shipping?

- Tinplate packaging contributes to product protection during shipping by providing a durable and sturdy material that acts as a barrier against external elements. It offers resistance to impacts, ensuring that the product inside remains safe and intact. Additionally, tinplate packaging has excellent corrosion resistance, preventing damage caused by moisture or humidity during transportation. This protective feature helps in preserving the quality and extending the shelf life of the product, reducing the risk of damage or spoilage.

- Q:Can tinplate be printed on?

- Yes, tinplate can be printed on.

- Q:What are the main challenges in tinplate canning process?

- The main challenges in tinplate canning process include ensuring proper sealing of cans to prevent leakage, maintaining consistency in can dimensions and shape, preventing contamination during the filling process, and ensuring efficient and cost-effective production while meeting quality standards. Additionally, addressing environmental concerns related to the disposal of tinplate waste and exploring alternative packaging materials are also significant challenges.

- Q:How is tinplate coated with organic coatings?

- Tinplate is coated with organic coatings through a process called electrolytic deposition. This involves immersing the tinplate in an electrolyte solution and passing an electric current through it. The organic coating materials, typically polymers or resins, are dissolved in the electrolyte solution and are attracted to the charged surface of the tinplate. As the electric current passes through, the organic coating materials are deposited onto the tinplate, forming a protective layer.

- Q:What are the common challenges in processing tinplate?

- Some common challenges in processing tinplate include ensuring proper coating adhesion, preventing tinplate corrosion, managing the formation of tin whiskers, and achieving consistent thickness and flatness in the tinplate sheets. Other challenges may include controlling the tinplate's surface quality, preventing contamination during processing, and ensuring proper handling and storage to avoid damage.

- Q:Can tinplate be used for musical instruments?

- Yes, tinplate can be used for certain musical instruments, particularly for cymbals and some percussion instruments. Tinplate is known for its resonance and durability, making it suitable for creating specific sounds and tones in these instruments. However, it is not commonly used for other types of musical instruments such as woodwinds or strings.

- Q:How is tinplate coated on both sides?

- Tinplate is coated on both sides through a process called electrolytic tinning. In this method, a thin layer of tin is applied to both sides of a steel sheet by immersing it in an electrolyte solution and passing an electric current through it. The positive electrode is made of tin, and the negative electrode is the steel sheet. This causes tin ions from the positive electrode to deposit onto the steel sheet, resulting in a uniform coating on both sides.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Empty Aerosol Spray Can For Hair Care, 57mm

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 pc

- Supply Capability:

- 30000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords