ER70S-6 Copper Coated Welding Wire

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 Tons m.t.

- Supply Capability:

- 20 Tons per Week m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

ER70S-6 Copper Coated Welding Wire

Material: copper coated carbon steel

Wire dia: 0.8/0.9/1.0/1.2/1.6mm

Packing: 15/20kgs/plastic spool/box, 72boxes/pallet

er70s-6 welding wire/ copper welding wire

1.Material:copper coated carbon steel

2.Wire diameter:0.8/0.9/1./1.2/1.6mm

3.Packing:15/20kgs/plastic spool/box, 72boxes/pallet.

4.Usage:

welding wire has excellent mechanical performance such as depositing speed and high efficiency, stable arc, little splash , good welding seam, strong resistance to surface scales and oil stains on the base metal, mainly used for welding low carbon alloy steel, industries of vehicles, bridge-engineering, machine-engineering, steel structures, shipping manufacture.

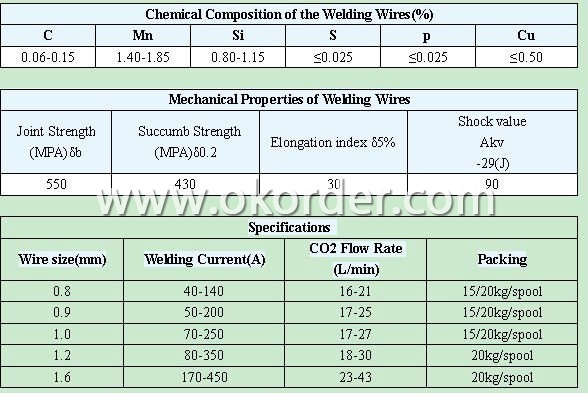

5.specification

- Q:Can ER308 welding wire be replaced by ER321?

- Can ER308, the national brand is H08Cr21Ni10Si, ER321 national brand is H08Cr19Ni10Ti, ER321 and ER308 compared to Cr-Ni elements had little difference, just add ER321 stabilization element Ti can improve the intergranular corrosion resistance of weld

- Q:What does "GHS-70" wire mean?

- GHS-70 is a 700Mpa grade high strength steel welding wire, which has excellent comprehensive mechanical properties. GHS-70 adopts mixed gas, it can weld the low strength alloy steel structure of corresponding strength level, and is widely used in the welding of hydraulic support and scraper chain wheel of coal mine machinery.The welding wire is made of H08Mn2SiA wire rod steel, drawn and treated by surface copper plating. It is used as CO2 gas shielded welding wire, with less spatter and good anti porosity performance.Application: Welded low carbon steel and some low alloy steel structure.The chemical composition of welding wire (%) C = 0.11 Si:0.65~0.95 Mn:1.80~2.10 = 0.20 Cr Ni = 0.30, S = 0.030, P = 0.030, Cu = 0.50Electrode diameter: 0.8, 1, 1.2, 1.6, 2, 2.5, 3.2 (mm)Attentions: clean the oil and rust on the surface of the workpiece before welding, and select the suitable welding specification.

- Q:Two how many kinds of wire welding equipment are needed? How much do you charge for a set? Thank you.

- Two wire equipment needs pretreatment equipment, Mary eighth boron coated tank drawing machine, CNC precision pull straight wiredrawing machine, expansion of copper production line, winding machine can be produced; a set of 10 hours of production of 1.2 wire 3 tons of equipment prices in 550 thousand.

- Q:Which kind of welding wire is needed for the welding of No. 20 steel and 316L?

- 316, mainly corrosion resistant stainless steel, so the weld must meet the performance of 316 materials, it is recommended to use ER 316 L welding wire.

- Q:308, 3o9 stainless steel wire component, 309 instead of 3O8, okay?

- First of all, it can not be replaced.308 is welding 304 plate welding wire, 309 mainly welding carbon steel and stainless steel butt welding wire, mainly used for welding different materials.308 ingredients: H08CR21NI10Si (YB/T5092)309 ingredients: H12CR24NI13SI (YB/T5092)

- Q:What kind of welding wire is used for 310S stainless steel plate?

- Hello, should 310S argon arc welding wire be ok

- Q:What is the advantage of welding wire without copper plating?

- The copper plating wire at the beginning to rust, but in the use of the process can also be found conductive, the worst is the operator in the use process of smoke inhalation of copper is harmful to the body, and the production process will emit large quantities of sewage (which contains alkali, acid, borax, copper sulfate) of serious pollution to the atmospheric environment; the production process is now copper coated wires, no sewage nor copper smoke, small splash, small smoke (no copper smoke), good shape, environmental protection and energy saving.

- Q:Can gas shielded welding welding aluminum welding wire?

- You can put the wire into U, rotation gear, wire feeding hose for Chengtefurong, gun into the water. That's it.

- Q:Is there any difference between stainless steel wire and stainless steel wire?

- There is a certain difference, since the stainless steel welding wire is used as the jointing material for welding, and some elements are added, it can protect the welding seam and be suitable for the fusion of welding wire and base metal. Stainless steel wire alone does not consider its weldability during the forging process, in which the main guarantee is the metallic properties of the stainless steel itself

- Q:What are the characteristics of fuses? What are the properties of welding wire?

- A fuse is also called a fuse, and the IEC127 standard defines it as a fuse (fuse-link)". The utility model relates to an electric component which is arranged in a circuit and ensures the safe operation of the circuit. When the current flows through the conductor, the conductor will be heated because of the resistance of the conductor. And heat follow this formula: Q=0.24I2RT; Q is the heat, the 0.24 is a constant, I is the current flowing through the conductor, R is the resistance of a conductor, T is the current through the conductor time; so the formula we can see that the principle of simple fuse.1 、 over current protection and over temperature protection. A fuse used for overcurrent protection is a fuse (also called a current limiting fuse) as it usually is.2. Fuses used for overheating protection are generally referred to as "temperature fuses"". The temperature fuse is divided into the low melting point alloy shape and the temperature sensitive trigger shape, as well as the memory alloy shape and so on. The temperature fuse is used for preventing the heating appliance or the heating device from being too high and the temperature is too high to protect.Welding wire is used as filler metal or metal wire welding material at the same time as conductive.1, in gas welding and gas tungsten arc welding, welding wire for filler metal;2. In submerged arc welding, electroslag welding and other gas shielded arc welding, the welding wire is both a filler metal and a conductive electrode.3, the surface of the wire is not coated with anti oxidation flux.

1. Manufacturer Overview |

|

|---|---|

| Location | Hebei,China |

| Year Established | 2005 |

| Annual Output Value | |

| Main Markets | South America Southeast Asia Africa Mid East Eastern Asia South Asia |

| Company Certifications | ISO 9001:2000;ISO 9001:2008;ISO 17799 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | XINGANG |

| Export Percentage | 91% - 100% |

| No.of Employees in Trade Department | 11-20 People |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | 5,000-10,000 square meters |

| No. of Production Lines | 10 |

| Contract Manufacturing | |

| Product Price Range | Average |

Send your message to us

ER70S-6 Copper Coated Welding Wire

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 Tons m.t.

- Supply Capability:

- 20 Tons per Week m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords