EWR

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10Ton kg

- Supply Capability:

- 100TON PER TON kg/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

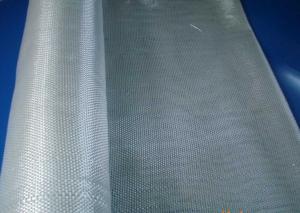

Specifications of EWR

1) Density (ends/cm): 3 x 3

2) Breaking strength (N): 2700 x 2500

3) Good quality

4) White color

5)plain weave

Applification of EWR

1) Width: 1000mm

2) Weight: 600±60g/m2

Packaging & Delivery of EWR

Packaging Detail: fiberglass fabric:plastic woven bag or carton,according custormers' demand

Delivery Detail: (15-20)days after received the deposit

- Q:Does anyone know what kind of sculpture of glass fiber reinforced plastic sculpture is?

- First of all, strictly speaking, this is not a sculpture, but a process made of glass fiber reinforced plastic. Because the material is light, the production cost is relatively low, large so-called sculpture, with this craft is indeed cost-effective. In simple terms, the glass steel process to want to do what products, the first to have a real, such as plaster production, large sculpture, a hollow lining on the surface of plaster sculpture physical model, glass steel process on the basis of type (a process that must be done such as stripping a ball type, must be divided into two halves to release the same) make a mold, again handle this mold, including grinding and polishing and waxing here no longer supplement. The next step is to use the FRP process to make a material in this mold. So this is so simple, but the production of glass steel there are a lot of attention in the process, if you have their own interests, but also occasionally, rubber mold, wood, DIY gadgets or sculpture is a very happy thing.

- Q:Can fiberglass fabric be used for making protective sleeves?

- Indeed, protective sleeves can be crafted using fiberglass fabric. Renowned for its durability, heat resistance, and capacity to endure soaring temperatures, fiberglass fabric proves to be an exceptional option for such sleeves, particularly in industries where laborers confront intense heat or perilous substances. By furnishing a dependable shield against heat, flames, chemicals, and abrasions, fiberglass fabric effectively safeguards the wearer's arms from potential harm. Moreover, its lightweight and flexible nature ensure the wearer's comfort and facilitate effortless mobility.

- Q:What are the characteristics of glass fiber acoustic panels?

- To effectively control and adjust the reverberation time, reduce noise, improve the sound absorbing ceiling. Glass fiber has the heat insulation performance is very good, for air-conditioned venues, can reduce the indoor temperature outside, so as to effectively save energy. The glass fiber acoustic ceiling almost does not absorb moisture from the air, moisture resistance is excellent, can flatness from size to stability in any humid environment.

- Q:Can fiberglass fabric be used for making conveyor belts?

- Indeed, fiberglass fabric possesses the capability to be utilized in the creation of conveyor belts. Renowned for its exceptional robustness and longevity, fiberglass fabric proves itself fit for purposes demanding uninterrupted motion and substantial burdens, exemplified by conveyor belts. Moreover, its capacity to withstand elevated temperatures, chemicals, and abrasion renders it an optimal substance for the manufacturing of conveyor belts. In addition, fiberglass fabric's lightweight nature, flexibility, and effortless maneuverability contribute to the efficient production of conveyor belts.

- Q:Can fiberglass fabric be used for wall coverings?

- Yes, fiberglass fabric can be used for wall coverings. Fiberglass fabric is a versatile material that offers several benefits for wall coverings. It is lightweight, durable, and has excellent resistance to moisture, mold, and mildew. These properties make it an ideal choice for areas that are prone to high humidity, such as bathrooms or kitchens. Additionally, fiberglass fabric can be easily installed on walls, either by using adhesive or by stapling it to the surface. It can also be painted over, allowing for a customized finish that matches the desired interior design. Moreover, fiberglass fabric is fire-resistant, making it a safer option for wall coverings. It has a high melting point and does not emit toxic fumes when exposed to fire, which is an important consideration for building safety. Overall, fiberglass fabric is a practical and versatile choice for wall coverings, offering both aesthetic appeal and functional benefits.

- Q:What does "PCB" mean?

- We can't transmit electrical signals just as insulation plates, so we need to cover the surface with copper. So we call the PCB board a copper clad substrate. In the factory, the common copper substrate in this code is FR-4, each card manufacturers which in general there is no difference, so we can think of everyone at the same starting line, of course, if it is best to use high frequency board, copper clad PTFE glass cloth laminate high cost. The process of copper is very simple, generally can be made by rolling and electrolytic solution, the so-called rolling is Gao Chundu (>99.98%) of the copper rolling method on the PCB substrate, because the adhesive has excellent epoxy resin and copper foil, copper foil adhesive strength and high working temperature, can be no bubble dip in the molten tin is 260 DEG C in. This process is like rolling dumpling wrappers, but the dumpling wrappers are thin and thin. The thinnest is less than 1mil (industrial unit: mil, 1/1000 inches, equivalent to 0.0254mm)! If the dumpling wrappers are so thin, the pot must leak! The so-called electrolytic copper in junior high school chemistry has learned, CuSo4 electrolyte can continuously manufacture a layer of "copper foil", this is more easy to control the thickness, the longer the copper foil the more thick! Usually the factory has strict requirements on the thickness of copper foil, usually between 0.3mil and 3mil, and has a dedicated copper foil thickness tester to test its quality. Like old radios and amateur PCB, copper is especially heavy, and the quality of the factory is far worse than the computer board.

- Q:Can fiberglass fabric be used for making molds?

- Yes, fiberglass fabric can be used for making molds. It is a popular choice due to its strength, durability, and ability to easily conform to different shapes. Fiberglass fabric is commonly used in the mold-making process to create lightweight, yet sturdy molds for various applications such as in the automotive, aerospace, and construction industries.

- Q:How does fiberglass fabric perform in corrosive environments in chemical plants?

- Fiberglass fabric is highly resistant to corrosion and performs exceptionally well in corrosive environments in chemical plants. Its non-reactive nature and excellent chemical resistance make it an ideal choice for protecting equipment and structures from the damaging effects of corrosive substances. Additionally, fiberglass fabric has a high tensile strength and is lightweight, making it easy to install and maintain. Overall, fiberglass fabric offers long-lasting durability and reliability in corrosive environments, ensuring the safety and efficiency of chemical plant operations.

- Q:Can fiberglass fabric be used for making heat-resistant clothing?

- Yes, fiberglass fabric can be used for making heat-resistant clothing. Fiberglass fabric is known for its excellent heat resistance properties, as it can withstand high temperatures without melting or igniting. It is commonly used in industries where workers are exposed to extreme heat, such as firefighters, foundry workers, and those working in the aerospace industry. Fiberglass fabric has the ability to provide thermal insulation, protecting the wearer from heat-related injuries. Additionally, it is lightweight and flexible, making it suitable for creating comfortable and durable heat-resistant clothing. However, it is important to note that fiberglass fabric can be itchy and irritating to the skin, so appropriate lining or protective layers are often used to minimize contact between the fabric and the wearer's skin.

- Q:What are the different fiberglass fabric finishes for chemical resistance?

- There are several different fiberglass fabric finishes available for chemical resistance, including silicone, PTFE (polytetrafluoroethylene), neoprene, and vinyl. These finishes are applied to the fiberglass fabric to provide a protective barrier against various chemicals, making the fabric suitable for use in industries such as chemical processing, oil and gas, and wastewater treatment. Each finish offers different levels of resistance to specific chemicals, so the choice of finish will depend on the specific needs and requirements of the application.

Company respected "steadfast, perseverance, responsibility" spirit of enterprise, and with integrity, win-win and create a business philosophy, to create a good environment of enterprise, with new management mode, perfect technology, and thoughtful service, excellent quality for survival, we always adhere to customer first service to customers, insist on their service to impress customers.

1. Manufacturer Overview |

|

|---|---|

| Location | Shanghai,China |

| Year Established | 2006 |

| Annual Output Value | Above US$20 Million |

| Main Markets | Mid East;Western Europe;North America:South American |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 70% |

| No.of Employees in Trade Department | 200 People |

| Language Spoken: | English;Chinese |

| b)Factory Information | |

| Factory Size: | Above 400,000 square meters |

| No. of Production Lines | Above 15 |

| Contract Manufacturing | Average |

| Product Price Range | OEM Service Offered;Design Service Offered |

Send your message to us

EWR

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10Ton kg

- Supply Capability:

- 100TON PER TON kg/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords