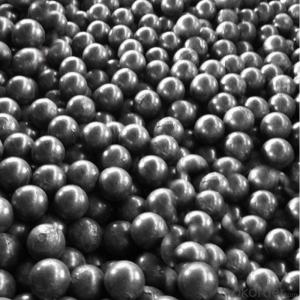

G10-G120 Steel Shot with ISO9001 & SAE Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Product Description

Product Description:

1.18 years on metal abrasives manufacturing and exporting.

2. Delivery within 15 days.

3. Full transport insurance.

4. Sell to 32 countries on 5 continents.

Product Picture:

Size:

S780, S660, S550, S460, S390, S330, S280, S230, S170, S110, S70

Chemistry Composition:

| C | Mn | Si | S | P |

| 0.70-1.20% | 0.60-1.20% | 0.40-1.20% | ≤0.05% | ≤0.05% |

Average degree of hardness:

| Normal | 40-50HRC (377-509HV) |

| Special | 52-56HRC (543-620HV) |

| Special | 56-60HRC (620-713HV) |

| Minimum density | 7.4g/cm3 |

Package:

25kgs/bag, 40bags/ton/pallet

1000kgs/ton bag

Product Standard:

SAE J827

We press American Cast steel association strictly"SFSA20-66 The Cast steel whets to anticipate the standard", American automobile engineer's association"SAE J1993Cast Steel GritThe standard", the People's Republic of China black metallurgy profession"YB/T5150-1993Cast Steel GritThe standard", the American soldier mark"MIL-S -851CTidy up and enhance to use the metals steel sand and the steel pill"and the nations standardize organization" ISO11124-3High carbon Cast steel pillCast Steel Grit Standard"the future life produce.

Product use:

Cast steel shot is wildly used for cleaning the rust of metal surface and the reinforced of metal parts. Such as Foundry Industry, Shipbuilding Industry, Container Industry, Marble Cutting, Petroleum Pipeline, Automotive Industry etc.

- Q:How is steel used in the production of storage tanks and containers?

- Steel is commonly used in the production of storage tanks and containers due to its strength, durability, and corrosion resistance. It provides a reliable and secure option for storing various fluids and materials, including water, chemicals, and petroleum products. Additionally, steel can be easily molded and fabricated into different shapes and sizes, making it versatile for different storage requirements.

- Q:What are the different types of steel products used in the manufacturing of gardening tools?

- Some of the different types of steel products used in the manufacturing of gardening tools include stainless steel, carbon steel, and alloy steel. Stainless steel is commonly used for its corrosion resistance and durability, making it suitable for tools exposed to moisture and outdoor conditions. Carbon steel is known for its strength and toughness, making it suitable for heavy-duty tools that require sharp edges, such as pruning shears or hedge trimmers. Alloy steel, a combination of different metals, offers a balance between strength, durability, and affordability, making it a popular choice for various gardening tools like shovels, rakes, and hoes.

- Q:What are the different grades of tool steel and their applications?

- Tool steel is a type of high-quality carbon or alloy steel that is specifically designed for use in the manufacturing of tools and machinery parts. There are several different grades of tool steel, each with its own unique properties and applications. Some common grades include: 1. O-1 Tool Steel: This grade is known for its excellent hardness, wear resistance, and toughness. It is commonly used in making cutting tools, punches, and dies. 2. A-2 Tool Steel: A-2 grade offers good wear resistance and machinability. It is often used in applications requiring high production rates and precision, such as forming dies and precision measuring tools. 3. D-2 Tool Steel: D-2 grade is a high-carbon, high-chromium, and high-molybdenum steel. It exhibits excellent wear resistance and can retain its hardness even at high temperatures. It is widely used in making cutting tools, shear blades, and cold work punches. 4. H-13 Tool Steel: H-13 grade is a hot work tool steel with excellent heat resistance and high toughness. It is commonly used in applications that involve high temperatures, such as die casting, extrusion, and hot forging. 5. M-2 Tool Steel: M-2 grade is a high-speed tool steel known for its exceptional hardness and heat resistance. It is commonly used in making drills, reamers, and other cutting tools that require high-speed machining. These grades are just a few examples, and there are many other tool steel grades available, each suited for specific applications. The choice of grade depends on factors such as the desired hardness, wear resistance, toughness, and the specific tool or part being manufactured.

- Q:How are steel tubes used in plumbing and HVAC systems?

- Steel tubes are commonly used in plumbing and HVAC systems due to their strength, durability, and resistance to corrosion. In plumbing, they are used to transport water, gas, and other fluids from one point to another. In HVAC systems, steel tubes are utilized for the distribution of air, refrigerants, and other gases. Their ability to withstand high pressure and temperature makes them a reliable choice for these applications. Additionally, steel tubes are often preferred for their ease of installation and maintenance, ensuring efficient functioning of plumbing and HVAC systems.

- Q:How is steel used in the production of laboratory equipment?

- Steel is used in the production of laboratory equipment due to its durability, corrosion resistance, and high heat resistance. It is commonly used to manufacture items such as lab benches, cabinets, fume hoods, and various tools and instruments.

- Q:What are the advantages of using stainless steel in the food and beverage industry?

- One of the main advantages of using stainless steel in the food and beverage industry is its excellent resistance to corrosion. This means that stainless steel equipment and surfaces are less likely to rust, stain, or corrode when exposed to various substances commonly found in the industry, such as water, acids, and food ingredients. Additionally, stainless steel is easy to clean and maintain, as it is non-porous and does not absorb dirt, bacteria, or odors. This makes it a hygienic choice for food processing and handling. Moreover, stainless steel is durable and can withstand high temperatures and mechanical stress, making it suitable for a wide range of food and beverage applications.

- Q:How is steel plate heat-treated for optimal strength?

- Steel plate is heat-treated for optimal strength through a process called quenching and tempering. First, the steel plate is heated to a high temperature, known as the austenitizing temperature, which allows the carbon in the steel to dissolve uniformly. It is then rapidly cooled by immersing it in a quenching medium, such as oil or water, to transform the crystal structure into a hard martensitic phase. Subsequently, the plate is reheated to a lower temperature and held for a specific period to temper the martensite, reducing its brittleness while maintaining a significant level of strength. This heat treatment method enhances the hardness, toughness, and overall mechanical properties of the steel plate, making it ideal for various applications requiring optimal strength.

- Q:How is steel used in the construction of industrial buildings and warehouses?

- Steel is commonly used in the construction of industrial buildings and warehouses due to its strength, durability, and versatility. It is used for the main structural framework, including beams, columns, and trusses, providing stability and support for the entire structure. Additionally, steel is utilized for roofing and siding, offering protection against weather elements and ensuring a long lifespan. Its ability to be easily fabricated and assembled makes it ideal for large-scale construction projects, enabling faster and more efficient construction processes.

- Q:What are the different types of steel reinforcement meshes?

- There are several different types of steel reinforcement meshes used in construction, including welded wire mesh, expanded metal mesh, and ribbed or deformed steel bars.

- Q:How are steel products used in the construction of theme-based resorts and hotels?

- Steel products are widely used in the construction of theme-based resorts and hotels due to their durability, strength, and versatility. They can be used in various structural elements such as beams, columns, and trusses, ensuring the stability and safety of the building. Additionally, steel is often utilized for designing iconic features and architectural elements, such as unique facades, grand entrances, and intricate detailing. Its ability to withstand extreme weather conditions and support heavy loads makes it an ideal choice for constructing large, expansive spaces within resorts and hotels. Overall, steel products play a crucial role in creating visually appealing and structurally sound theme-based resorts and hotels.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

G10-G120 Steel Shot with ISO9001 & SAE Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords