Geonet with High-Density Polyethylene (HDPE) and Ultravioresistant

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 g/m²

- Supply Capability:

- 100000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Specification---Geonet

Introduction: Geonet is made of high-density polyethylene (HDPE) and the ultravioresistant

agent

Features:

1.Aging resistance

2.Erosion resistance

3.Good Flexibility

Application:

1. Using the geonet on the roadbed of the roadway and railway can distribute the load effectively, improve the loading capacity and the stability of the roadway, and prolong its service life.

2. Spreading the geonet on the slope of road can prevent landslides, conserve water and soil, beautify the environment.

3. Spreading the geonet in the dyke protection in the reservoir and the river can protect it from the landslide.

4. Using the geonet in the coast engineering can amortize the concussion and the erosion of the

surf

Properties of geonet

Item Spec | CE121 | CE131 | CE151 | CE181 | DN1 | HF10 |

Mass per unit area (g/㎡) | 730±35 | 630±30 | 550±25 | 700±35 | 750±35 | 124±60 |

Mesh size (mm) | (8±1)× (8±1) | (27±2)× (27±2) | (74±5)×(74±5) | (90±10)×(90±10) | (10±1)×(10±1) | (10±1)×(6±1) |

Width(m) | 2 or 2.5 | |||||

Length(m) | 50 or 40 | |||||

Maximum tensile strength (KN/m)≥ | 6.2 | 5.8 | 5.0 | 5.77 | 6.0 | 18 |

Note: The special spec or size can be manufactured according to the demands of the contract

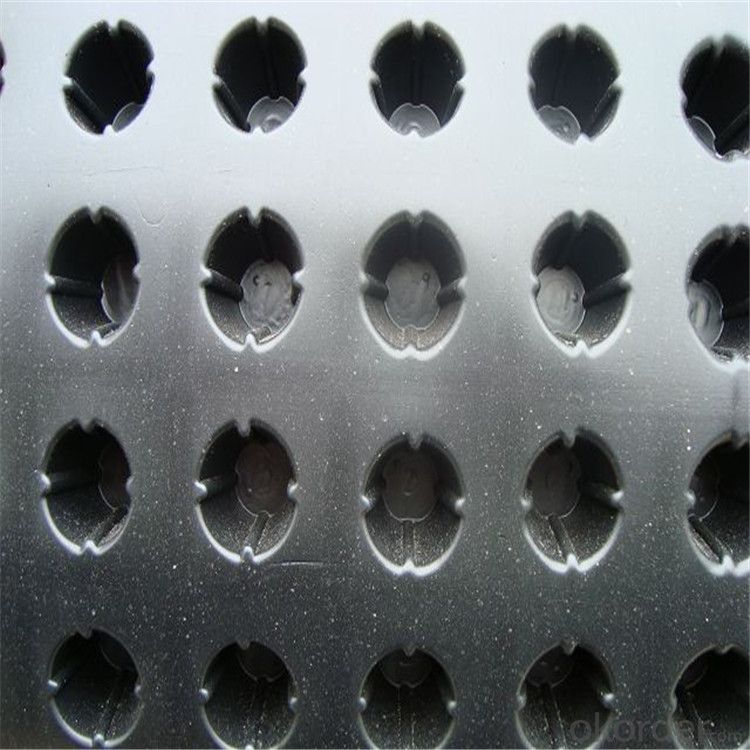

Images of Geonet

- Q:What are the advantages of using geotextile mattresses?

- Geotextile mattresses offer several advantages, including erosion control, slope stabilization, and protection against scouring. They are easy to install and provide immediate protection to underlying surfaces. Additionally, these mattresses are permeable, allowing for the passage of water while retaining soil particles, which helps in sediment control and the prevention of clogging. Moreover, geotextile mattresses are durable and resistant to UV degradation, making them a cost-effective solution for various civil engineering and environmental projects.

- Q:What are the advantages of using geotextile tubes for erosion control on beaches?

- Geotextile tubes offer several advantages for erosion control on beaches. Firstly, they provide a cost-effective solution compared to traditional methods such as seawalls or groynes. Secondly, they are environmentally-friendly as they allow for natural sand movement and dune formation. Additionally, geotextile tubes are highly durable, resistant to storms and waves, and can be easily installed and removed. Lastly, they can be customized in size and shape to fit specific project requirements, making them a versatile and efficient erosion control measure.

- Q:How can geocomposites be used in subsurface irrigation systems?

- Geocomposites can be used in subsurface irrigation systems by acting as a barrier to control water flow, preventing soil erosion and enhancing water distribution to plant roots. They help to evenly distribute water throughout the irrigation area, reducing water waste and increasing efficiency. Additionally, geocomposites can improve the overall performance and longevity of the irrigation system by providing stability and protection against clogging and root intrusion.

- Q:Are earthwork products suitable for both residential and commercial projects?

- Yes, earthwork products are suitable for both residential and commercial projects. Whether it is for constructing foundations, grading land, creating retaining walls, or landscaping, earthwork products such as soil, gravel, rocks, and sand can be used in a variety of projects regardless of their scale or purpose.

- Q:What are the specific applications of geosynthetic clay liners in landfill projects?

- Geosynthetic clay liners (GCLs) have specific applications in landfill projects primarily for their exceptional hydraulic performance and containment capabilities. GCLs are used as a barrier system within landfills to prevent the migration of leachate, which is the liquid produced by the decomposition of waste, into the environment. They serve as an effective hydraulic barrier, ensuring that leachate is contained within the landfill and does not contaminate adjacent soil or groundwater. Additionally, GCLs provide a cost-effective solution for landfill projects due to their ease of installation and low maintenance requirements. They can be quickly and efficiently placed, reducing construction time and costs. The clay component of GCLs swells upon contact with water, creating a self-sealing effect that enhances their containment ability. Furthermore, GCLs offer excellent chemical resistance, making them suitable for containing a wide range of waste materials, including hazardous and industrial waste. The liners effectively prevent the migration of pollutants from the landfill into the surrounding environment, safeguarding both human health and ecosystems. Overall, the specific applications of geosynthetic clay liners in landfill projects revolve around their ability to provide an impermeable barrier, resist chemical degradation, and offer cost-effective installation and maintenance, ensuring the containment of leachate and protection of the environment.

- Q:Discussion on the importance of materials in civil engineering

- No material, you become archaeological. Only digging!

- Q:Civil engineering materials in the two grinding a burning what does this mean

- Refers to the cement material, cement is the first stone and other raw materials, grinding, and then after high temperature calcination, and then after grinding into powder

- Q:What are the different types of geocells available in the market?

- There are several different types of geocells available in the market, including honeycomb, diamond, and hexagonal cell designs. Each type has its own unique features and benefits, but they all serve the common purpose of providing soil stabilization and erosion control in various applications such as road construction, slope protection, and retaining walls.

- Q:Such as steel, cement, coarse aggregate, fine aggregate, anchor. The The Is it a concrete definition?

- Engineering need to do the re-test of raw materials: steel, brick, cement, sand, stone (if it is not a commodity concrete) waterproof coating, waterproof membrane

- Q:What are the advantages of using geosynthetic materials in road shoulder construction?

- There are several advantages of using geosynthetic materials in road shoulder construction. Firstly, geosynthetics provide excellent soil stabilization, preventing erosion and maintaining the integrity of the road structure. Secondly, they can improve drainage by allowing water to pass through while preventing soil particles from clogging the system, thus reducing the risk of water-related damage. Thirdly, geosynthetics are durable and resistant to degradation, ensuring long-lasting performance and reducing the need for frequent maintenance. Lastly, these materials are lightweight and easy to install, resulting in cost and time savings during construction. Overall, geosynthetics offer numerous benefits for road shoulder construction, enhancing the safety, durability, and efficiency of the road network.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Geonet with High-Density Polyethylene (HDPE) and Ultravioresistant

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 g/m²

- Supply Capability:

- 100000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords