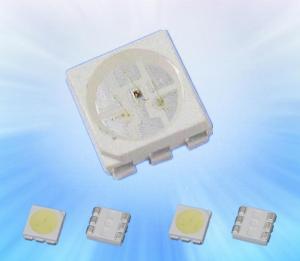

high luminance 2835 CRI >80 performance light emitting diode LED

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4000 PCS

- Supply Capability:

- 18000000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1. Features & Benefits

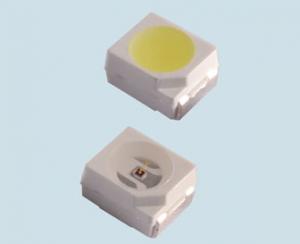

- Package: 2.8*3.5*0.65mm (Top view white LED)

- Emitted Color: White

- Soldering methods: All SMT assembly methods

- Enables 3-, 4-, 5-step MacAdam ellipse kits

- Extremely wide viewing angle,standard form factor design flexibility

The minimum luminous efficiency 160lm/w@60mA

2. Typical Application:

- Bulb

- ndoor & Outdoor sign board back light

- Advertising backlighting

- General use.

3. Precautions for use

3.1 Soldering

SMD LED encapsulation is very flexible, outside force easily demolish radiant surface and plastic, As soldering , Please handle with care!

a. With No-clean Flux, according to reflow soldering cure condition when soldering, Reflow soldering should not be done more than two times, simultaneity you must insure clean on the radiant surface. Otherwise, foreign objects can affect radiant color.

b. Don’t process manual soldering except repair. Recommended to be soldered with 25W Anti-static iron, The temp. of the iron should be lower than 300℃ and soldering time should not be done more than three seconds, at the same time iron can’t touch radiant surface and plastic.

c. Don’t twist LED in course of manual soldering and experiment, Otherwise, the lights will not work possibly.

d. Please use the same BIN grade in one panel, and don’t mix the difference BIN grade in one panel when soldering. Otherwise, it will cause a serious uneven color problem.

e. Please control the sulfur content of solder paste and PCB.

f. Pb-free solder temp.-time profile as below:260℃Max.

3.2 Cleaning

a. Don’t be cleaned with ultrasonic. Recommended to be wiped with isopropyl alcohol or pure alcohol,wiping time should not be more than one minute. LED must be placed at room temperature for fifteen minutes before producing .you must insure clean on the radiant surface. Otherwise, foreign objects can affect radiant color.

b. LED can’t be in contact with acetate、 trichloroethylene, acetone、 sulfur、 nitride、 acid、 alkali、 salt. These matters can destroy LED.

3.3 Sealing

a. Sealing glue can’t contain sulfur,because these matter can affect fluorescence powder poisoning.

b. When using normal sealing glue, recommended will be operated life for 168hrs under normal temperature.

3.4 Storage

a. Don’t open the moisture proof bag before ready to use the LEDs.

b. The LEDs should be kept at 30℃ or less and 60%RH or less before opening the package. The max. period before opening the package is 1 year. c. After opening the package, the LEDs should be kept at 30-35%RH or less, and it should be used within 3 days. If the LEDs should be kept at 30-35%RH or more, and it should be used within 4 hours.

d. If the LEDs be kept over the conditions of 20%, baking is required before mounting. Baking condition as below: 70±5℃ for 12 hours for bulk goods, 105±5℃ for 1 hours for roll goods.

e. The environment have no acid、alkali、corrosive gas、intensively shake and high magnetic field.

3.5 Test

a. Customer must apply the current limiting resistor in the circuit so as to drive the LEDs within the rated current. Otherwise slight voltage shift maybe will cause big current change and burn out will happen.

b. Also, caution should be taken not to overload the LEDs with instantaneous high voltage at the turning ON and OFF of the circuit.

c. The reverse voltage mustn’t exceed 5v when lighting on or testing the LED, otherwise, LEDs will be damaged.

- Q:How can I install the patch LED lamp belt on the wood chip casting board? With double-sided glue will be hot, and can not use the clip on the screw, what should I do?

- With double-sided adhesive, the temperature will not be very high. So it won't fall either. That's how I got it. It took me more than half a year, and I didn't have any problems

- Q:Is the forward voltage drop of the patch LED too large or too small?

- Pressure drop does not mean good or bad, the greater the pressure drop, the better to choose the right for you

- Q:Patch LED light does not flash, why?

- Hit the meter on the buzzer and measure the patch individually. If the flash is a patch, the light goes off.

- Q:LED patches have several ways of welding. Which ones can be reflow? What can be done by eutectic welding? Is the welding of viscose and lens material is required?

- Chip and stent welding methods are: eutectic welding, silver glue fixed, resin insulation and fixed silicone rubber insulation fixedWelding beads: reflow soldering, hot plate welding and manual soldering.

- Q:What should I notice when I want to solder 1206 LED patch type luminous tube on fine copper wire?,

- The peak reflow temperature: 260 degrees or below this temperature. (surface temperature) 2 temperature over 210 DEG C required time: 30 seconds or less than this time. 3 reflow times: no more than two times. 4 after reflow, LED needs to be cooled to room temperature before contact with colloid.

- Q:LED package and LED SMD LED lamp, what is the difference? Will the release agent be used in that part?

- They differ in form and belong to the SMDLED category. Encapsulation uses liquid silicone and epoxy resins as well. The patches are basically made of epoxy resin. Relatively speaking, the amount of liquid silica should be relatively large.

- Q:Patch LED light broken one, short circuit can use it?

- Can not casually short-circuit, according to the LED connection, but also to see the power supply voltage and current, all the LED can not flow. Any short circuit may cause excess LED to flow over or over, causing a chain reaction, a bad string,...... .

- Q:What is the difference in performance between the LED plug-in and the LED patch?

- The cooling of the plug-in is not good, because the plug-in's lamp foot, in order to save costs, generally use iron plus coating, heat conduction is not very good.The strength of aluminium alloy is not enough, it is easy to break, and copper is expensive.Relatively speaking, the patch is good, because the heat is welded on the PCB, copper or direct aluminum substrate cooling, patches near.Otherwise, why do high-power patch it?!SMT direct placement machine, a high degree of automation, low rate of bad.

- Q:LED patch lamp band, how to calculate how many watts a meter, such as 3528-60 beads is how much?

- 3528 single lamp is 0.06W 0.06*60 lamp =3.6W 3528-60 bead is 3.6W/ meters

- Q:What does patch LED light mean?

- Look, what's your product?. Some products have volume requirements, straight line will be relatively large, patches of small affixed to the circuit board does not occupy space, if only the light source, it may be an ordinary light bulb, as LED power saving.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

high luminance 2835 CRI >80 performance light emitting diode LED

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4000 PCS

- Supply Capability:

- 18000000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords