Hydraulic Concrete Placing Boom PB17B3R hot sale

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 300 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

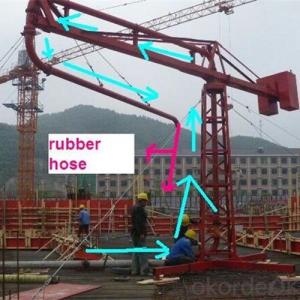

This hydraulic climbing type is ideal for high rise buildings, bridges and dams. Placed on tubular columns, they can climb up automatically with self-climbing system, enabling the concrete to be delivered exceptionally fast and cost-effectively.

1: The machine is fully hydraulic control and can slewing 360°

2: The balance valves are products of oilcontrol company of Italy and the solenoid directional valves are products of Rexroth Company of Germany

3: The main electric components are products of the world-renowned brand such as Omron or Schneider.

4: There are two modes of operation: radio remote control and cable remote control

Detailed Description

This hydraulic climbing type is ideal for high rise buildings, bridges and dams. Placed on tubular columns, they can climb up automatically with self-climbing system, enabling the concrete to be delivered exceptionally fast and cost-effectively.

1: The machine is fully hydraulic control and can slewing 360°

2: The balance valves are products of oilcontrol company of Italy and the solenoid directional valves are products of Rexroth Company of Germany

3: The main electric components are products of the world-renowned brand such as Omron or Schneider.

4: There are two modes of operation: radio remote control and cable remote control

| Model | PB17B3R | ||||||||||

| Performance | Max radius of Placing Boom(m) | 17 | |||||||||

| Free Standing height (m) | 12.75 | ||||||||||

| Slewing range(°) | 360 | ||||||||||

| Working temperature(℃) | -20~48 | ||||||||||

| Power(subject to customer) | 380V/50Hz | ||||||||||

| Motor | Power (kw) | 20 | |||||||||

| Hydraulic pressure(Mpa) | 20 | ||||||||||

| Hydraulic oil | Circumstance temperature 5℃-48℃ | ESSO NUTO H46 | |||||||||

| Circumstance temperature -20℃-5℃ | ESSO NUTO H32 | ||||||||||

| Mode of control | cable romote control | ||||||||||

| radio remote control | |||||||||||

| (for option)manual control | |||||||||||

| mode of slewing | gear slewing | ||||||||||

| Boom | Delivery pipe dimension | Φ133mm×4.5mm | |||||||||

| 1st section | length | 6.67 | |||||||||

| articulation | -4°~+90° | ||||||||||

| 2nd section | length | 5.73 | |||||||||

| articulation | 0°~180° | ||||||||||

| 3rd section | length | 4.61 | |||||||||

| articulation | 0°~180° | ||||||||||

| 4th section | length | / | |||||||||

| articulation | / | ||||||||||

| mode of climbing | Hydraulic cylinder climbing | ||||||||||

- Q:How to install and use the distributor?

- Install the fuse according to the electricity consumption. No steel, aluminum or zinc wire shall be used instead of the fuse.

- Q:How to distinguish tower type distributor and general distributor?

- No frame structure. Its stability and service life are all behind the tower cloth machine

- Q:How to fit the cloth rod of the distributor?

- When the cloth rod is placed on the frame, the leg is compacted by a support pipe, and the device is not necessary when being arranged on the floor of the building

- Q:What is the working principle of the distributor?

- In order to avoid the vibration disturbance of slab steel tubing, tubing must be located in the steel frame, steel bunk put wood as a springboard to the supporting surface, concrete pouring, pouring the casting from front to back, remove bracket until the Jiaowan demolished floor bracket

- Q:What do concrete pumps and fabrics mean?

- Pump truck, sub drag pump and automobile pump, drag pump delivery range is relatively large, the pipe can be used in the past (in the case of pumping pressure allowed), the disadvantage is that relatively cumbersome,

- Q:What are the acceptance items of concrete spreader?

- The installation site should be carried out in advance according to the requirements of construction site should be collected, must be stable and firm installation, foot pad.

- Q:What is the structure of a concrete distributor?

- Structure: bolt, and the vertical frame, which is fixed on the base part, through the slewing bearing and the top rotating part is connected on the main beam, and the balance arm, the balance arm rod, such that after the formation of the upper transverse rotating part

- Q:What's the design plan of the concrete spreader?

- The belt conveyor head sweeper is designed for the special requirement of conveying concrete and cleaning mortar. The scraper is made of hard alloy material, with a rectangular section, and it does not hurt the adhesive tape and the mortar loss is small

- Q:How to maintain the concrete spreader?

- Cloth machine material, Doumen hoist hydraulic with accumulator, can quickly open and close, accurate cloth, prevent residual material fall, pneumatic closed lax

- Q:What are the weekly inspection items for concrete spreader?

- Check connection bolts, shaft end plate, pin shaft, lock nut is loose

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hydraulic Concrete Placing Boom PB17B3R hot sale

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 300 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords