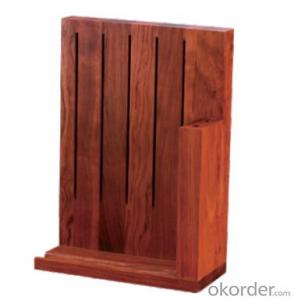

knife seat,F-KB010 acacia wood knife seat,your best choice

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

product name:acacia wood knife seat

material:acacia wood

N.W.:1.204kg

MEAS:23*19.5*6cm

Specifications:

Has the quite distinct shape of the mountain wood grain, and the contact surface is a good sense

Excellent toughness, process into various curved according to the needs , full of beauty

Solid texture,manufactured goods with firm structure,prolonged service life

The texture of rubber wood is fine and closely woven,pore full of lots ot padding so it's hard to absorb water and corrode.

Description:

1、The knife seat use material of high quality natural acacia wood and take professional advanced machine equipment and manual binding.

2、The knife seat was refined by material, assembly, polishing, painting and other procedures.

3、The knife holder has the advantages of real materials, excellent workmanship, mouldproof and moth proofing, anti bacteria, wear-resisting etc.

4、Hoteam commerce co.,LTD,is a manufactory specialized in all kinds of wood knife handles,wood seats,chopping boards and other woodworks.

5、Because the knife tool contact with tool wet food for long time, is very easy to breed bacteria, you should ensure that dry and clean and put it in the open air

acacia wood knife seat quantity:

Safety, health, bright color,durable,the everyday necessary good products

Anti-mildew change,anti moth

Environmental protection,no crack,no decay

- Q:4 station tool structure is the best. The detailed process of mechanical transmission, their demolition a few times, the worm brake to lift the knife. There is a problem in the rise of the knife in the process of the top cap of the spring to the top of the iron cover dead, the result of the death of the knife holder, can not drive. I estimate that the top cap and the angle and the first bevel on the iron cover are not consistent due to wear and tear. For I a person's opinion, hope you enlighten me

- This thing to have a picture to explain, the text can not express. Remove the countless times, the rotation of the motor makes the knife rises and then rotating, on top of a Hall element to detect the Holland tool you need is not to, to the motor reversal, falling knife stuck in the tooth is motor locked dead. There is a spring in the middle of the shaft and drives the two clips to play a key role. A lot of reasons for the death of the tool holder are caused by the broken line in the middle.

- Q:How to do the slide shoe

- Nails can be used as follows.Use a hammer to hammer the bigger one in the mouth, then screw it.In addition, there is a special tool for dealing with sliding wire. You can break a nail.Knife slide wire no way, can only change the tool holder. Even if the wire tapping to do the thread, the diameter is not the same as the original

- Q:These possibilities have been tested, or useless

- Look at the oil tank is not dirty or oil is not enough to clean the oil tank filter, there may be poor oil absorption.

- Q:Tool holder S solution

- Vertical typeThe wheel frame, in fact, is a parallel steel frame structure.Than S, there are many advantages.For example, solid, DIY, modification, etc.

- Q:The difference between the tool holder and the electric tool holder

- Methods with 980 for example: the first knife in the knife up one page T0010 for the input of X0Z0 cutter compensation in T0020 dabbler cutter compensation second page cutter compensation input X0Z0, the rest of the line.

- Q:CNC lathe turret, sometimes why turn around.

- Open the end of the tool holder, there is a bad disk or water. The solution uses the hair dryer to dry, if it is not OK to replace.

- Q:How can we remove the NC turret

- First remove the inside, then the following,Two screws inside, then the eye, should use a punch, turn down

- Q:1, CNC horizontal lathe tool holder with front and rear respectively. CNC vertical lathe tool holder how to classify?2, no matter front or rear CNC lathe, cutter movement from right to left (along the Z axis) with G42 compensation?

- 1: CNC vertical lathe no front and rear points, and it is different in general, the sleeper, knife in the right side of the center of the spindle, convenient use and debugging. The car generally have two knife, one is the vertical tool holder, but also often use the tool holder (according to different parts processing), can move up and down about (X, Z). One is the side of the knife, the general processing parts of the outer circle and the vertical knife can not be processed.2: personal understanding, CNC lathe general rarely used tool about compensation instruction, but to consider the nose arc, arc may result in the instruction of size and the size of the actual processing gap, but it can be in the compensation of tool interface, realize the compensation problem of the arc.

- Q:Drilling out of the hole is the overall deviation, the hole is 0.15, the cutting tool angle is not biased, the product is not how to jump, I was the first drilling after the chamfer, is how to go wrong, in this case, ask the teacher, thank you first, urgent...

- Hole overall bias, how much? What is not how to jump? Did you call the dial indicator? What is the actual beating?The drill hole 0.15, there are two reasons: one is that you have to drill the center hole with the center? Drill bit is not?Two is the drill axis and spindle axis coincidence? The center of the drill may be low or high, or is it crooked?There are so many uncertainties, drilling out of the hole is not too big strange.

- Q:NC turret is not in place

- Holzer element and outer ring position are not good. Please check.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

knife seat,F-KB010 acacia wood knife seat,your best choice

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords