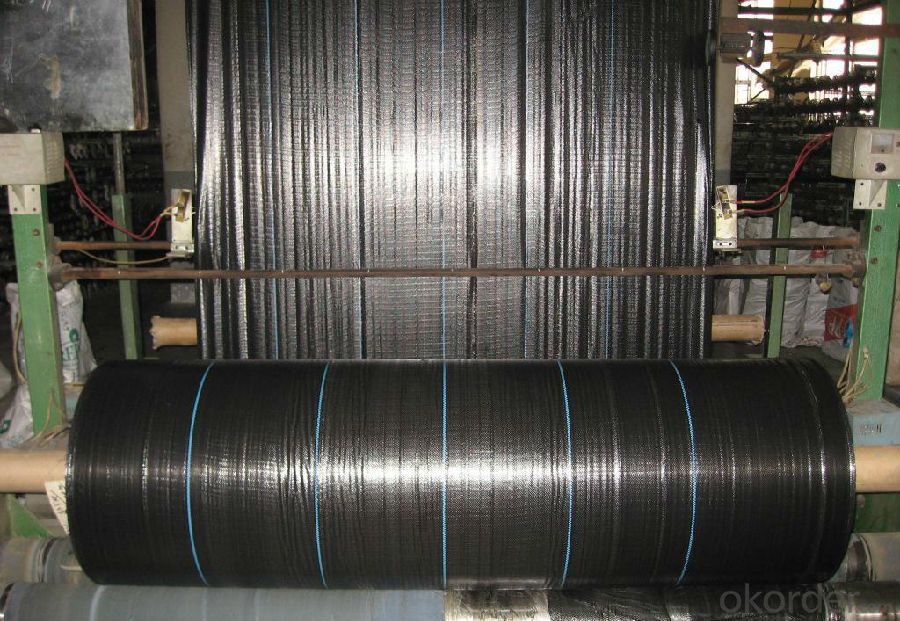

PP Geotextile for Road Construction/ Landscape/ Groundcover

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Landscape Geotextile Introduction

Landscape Geotextiles are composed from synthetic polypropylene/polyester fibres through a mechanical process of needling the fabric and adding, when necessary, a thermo fused process, resulting in a uniform porous structure with excellent tensile strength and chemical deterioration.

Type: 1. Wovens & knitted: use various fibre types in different combinations.

2. Non-wovens: staple or continuous fibres that are heat treated or needlepunched to “fix” fibres relative to each other.

Landscape Geotextile Specification

1) Weight / Mass: 75g/m2-400g/m2 .

2) Width: Within 8 m (1m-8m)

3) Length: 50m-100m/roll (as request)

4) Material: PP

5) Color: Black , white , grey, others

6) The biggest geotextile manufacturer/factory in China for many years . The equipment is introduced from Germany.

7) This geotextile can be made of polypropylene (PP).

8) The mass is available from 75g/m2 to 400g/m2 and the width available from 1.0m-8m, monolayer or multilayer (reinforcement geotextiles), long fiber or short fiber.

9) Color: all kinds of color are available. The annual production ability is 10 million square meters.

10) The fabric can also be heat treated by infrared at customer's requirements. Our geotextile are UV stabilized to give protection against aging under exposure to natural ultra-violet light.

Landscape Geotextile Application

1) Filtration

The filtration layer of the dykes, river canal, seacoast, concrete slope, retaining walls. At the same time of preventing the clay granule from passing, it allows the water and the gas pass through freely.

2) Separation:

The isolation of the railway dregs and the roadbed, roadbed and the soft base, surface of the airdrome and parking lot and the groundsill, different dam materials. It isolates the soil and the gravel of two kinds different granule pathway from the groundsill or other buildings.

3 )Reinforcement:

The highway, railway, soil-stone dam, breakwater, airport, backfill soil of retaining wall, slope protection, etc in which distributes the earth stress, prevents the side-displacement of the earth body and improves the earth body stability.

4 )Protection

It prevents the bank from being washed out, protects the bank and the bottom, prevents the water and soil from being washed away.

FAQ:

Q1: What is your minimum order quantity?

A:The minimum order quantity is 5000 ,but it is negotiable.

Q2:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

Q3:What is your delivery time?

A:Production time usually costs 2-20 days.

Waiting to cooperate with you!

- Q:How are geotextiles installed?

- Geotextiles are typically installed by first preparing the ground surface, removing any vegetation or debris. Then, the geotextile fabric is unrolled and laid over the prepared area. It is important to ensure that the fabric is properly aligned and overlaps are secured. The geotextile is then anchored or weighted down to prevent any movement. Depending on the specific application, additional layers of geotextile or other materials may be added. Overall, proper installation techniques are crucial to ensure the effectiveness and longevity of geotextile applications.

- Q:Can geotextiles be used in erosion control mats?

- Yes, geotextiles can be used in erosion control mats. Geotextiles are often used as a primary component in erosion control mats to prevent soil erosion by improving stability, drainage, and filtration.

- Q:Are geotextiles suitable for use in drainage ditches?

- Yes, geotextiles are suitable for use in drainage ditches. They are commonly used as a filter fabric to prevent soil erosion and retain sediment, while allowing the passage of water. Geotextiles also help in distributing the flow of water evenly throughout the drainage ditch, improving its efficiency and preventing clogging.

- Q:How do geotextiles help with soil confinement in erosion control bags?

- Geotextiles help with soil confinement in erosion control bags by providing a permeable barrier that retains the soil particles while allowing water to pass through. They prevent soil erosion by reinforcing the bags and stabilizing the soil, preventing it from being washed away by water or wind.

- Q:What are the advantages of using geotextiles in soil erosion prevention?

- There are several advantages to using geotextiles in soil erosion prevention. Firstly, geotextiles act as a physical barrier that helps to stabilize the soil, preventing it from being washed away by rain or other water sources. Additionally, geotextiles are permeable, allowing water to pass through while retaining the soil particles, thus reducing the impact of water flow on soil erosion. Moreover, geotextiles can be installed quickly and easily, providing an efficient and cost-effective solution for erosion control. Lastly, geotextiles are durable and resistant to degradation, ensuring long-term effectiveness in preventing soil erosion.

- Q:Do you have a drainage board and a geotextile on the basement roof?

- Hello, generally do not require re-test Huazhi geotextile materials, manufacturers need to answer for your needs

- Q:Can geotextiles be used in geotechnical engineering projects?

- Yes, geotextiles can be used in geotechnical engineering projects. Geotextiles are engineered fabrics that are commonly used to reinforce soil, separate different soil layers, and provide filtration and drainage in various geotechnical applications. They can improve the stability, strength, and performance of soil structures, such as retaining walls, embankments, and roadways, by effectively managing water flow and soil interactions.

- Q:What are the disadvantages of using geotextiles?

- One of the main disadvantages of using geotextiles is their potential for clogging and reduced permeability. Over time, fine particles and debris can accumulate within the geotextile, leading to reduced water flow and drainage. Additionally, improper installation or lack of maintenance can cause geotextiles to shift or tear, compromising their effectiveness. Moreover, geotextiles may not be suitable for all soil conditions or applications, as they may not provide adequate stability or strength in certain situations.

- Q:How do geotextiles help with pipeline protection?

- Geotextiles help with pipeline protection by acting as a barrier between the pipeline and the surrounding soil, preventing soil erosion and the formation of voids around the pipeline. They also provide additional support and reinforcement to the pipeline, reducing the risk of damage from external forces such as ground movement or heavy traffic. Furthermore, geotextiles can help with filtration, allowing water to pass through while preventing the migration of fine particles that could clog the pipeline. Overall, geotextiles enhance the longevity and structural integrity of pipelines, ensuring their safe and efficient operation.

- Q:Can geotextiles be used in underground storage tank installations?

- Yes, geotextiles can be used in underground storage tank installations. Geotextiles are often used as a protective barrier between the tank and the surrounding soil to prevent contamination and provide stability.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PP Geotextile for Road Construction/ Landscape/ Groundcover

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords