PPR Fitting Elbow with equal diameter on sales with Food Hygiene Regulations and Non-toxic

- Loading Port:

- Tianjin

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 11700 pc

- Supply Capability:

- 710000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Features

1. Corrosion resistance

PPR pipes and fittings can resistant to most chemical corrosion; it can withstand PH value range 1-14 high concentration of acid and alkali corrosion over a wide temperature range.

2. Installation performance

PPR pipe PPR pipe is light in weight, and the operation installation is easy, which make it available to weld again. It is very important that pipe and pipe fittings can be welded together in seconds with a simple tool. Compared to traditional connection methods it can save 40%~50% of the time.

3. Safety Indicators

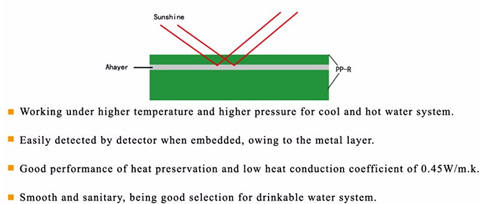

The basic component of PPR is carbon and hydrogen which is simple. It keeps in line with food hygiene regulations, non-toxic. If you use PPR pipe, there will no dirt in the inner wall or “secondary water pollution” caused by rust any more.PPR pipe ,green building materials, is more suitable for transporting drinking water.

Advantages of PPR pipe

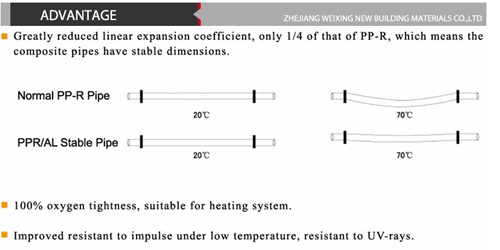

1. Maximum operating temperature can up to 95℃; it can work in a long term under the condition of 70℃ and 1.0Mpa.

2. PPR pipe density is only 1/8 of metal pipe; pressure resistance strength test is up 5Mpa, with good toughness, impact resistance.

3. Inner diameter of PPR pipe is little bigger than that of pipe fittings, which can ensure not to increase the resistance to fluid flow.

4. Inner wall of PPR pipe is smooth, no rust, no scaling, small fluid resistance

5. PPR pipe has excellent insulation properties, can significantly reduce the vibration and noise caused by the flow of liquid.

6. PPR pipe energy consumption is only 20% of steel pipe; its thermal coefficient is also only 1/200 of steel pipe, reducing heat loss greatly.

7. PPR pipe is poor electrical conductor material, which can avoid galvanic corrosion phenomena.

8. With poor thermal conductivity, PPR pipe can reduce condensation.

9. PPR pipes, fittings are recyclable.

Application

1. Hot and cold drinking water supply system of civil and industrial buildings

2. Clean, pure water piping system

3. Beverage production and transport systems

4. Industrial liquid delivery system

5. Central air conditioning system

6. Hot water circulation Heating System

7. Compressed air piping system

8. Garden and greenhouse irrigation systems

FAQ

PPR pipe and fittings selection principles

PPR pipe and fittings selection principles:

1. Note that the overall pipeline utilization factor C (ie a safety factor) to determine:

General case, and make long-term continuous temperature <70 ℃, optional C = 1.25; on important occasions and long-term continuous use temperature ≥70 ℃, and possibly a long time to run at higher temperatures, the optional C = 1.5;

2. For cold water (≤40 ℃) system, the choice of P.N1.0 ~ 1.6MPa pipe, tube; used for hot water systems use ≥PN2.0MPa PPR pipes and fittings.

3. After considering the above three principles, SDR pipe fittings should not exceed SDR pipe, pipe wall thickness that is not less than the same size of pipe wall thickness.

Points to note:

PPR pipes are widely used in industrial and residential buildings life, health and drinking water supply and hot water heating .There are two kinds of PPR pipes for hot and cold water. The cold water pipe wall is thin, hot pipe wall thickness, so that the hot water in terms of fracture resistance good performance of many pipe, hot water pipe prices are also more expensive than cold water pipe some of many manufacturers to be safe, hot and cold water, regardless of the construction process, cracking, improve the safety factor PPR pipe fittings which are applied to note the following Some applications often encountered in some cases, should pay attention.

1. PPR pipe fittings alone corrosion resistant can be applied to transport long items such as chemistry and strong adaptability to the environment. In order to ensure a good application of the pipe, installed outdoors or in direct sunlight must be wrapped dark protective layer.

2. Molding technique PPR pipes using, is the quality and credibility of security, leak, and note must be taken to prevent pipe expansion and deformation of technical measures in surface mounted or buried Concealed piping time.

3. PPR installation process should prevent paint and other organic pollutants and pipes and fittings in contact.

4. PPR pipe fittings hot melt connection safe, odorless, in which the connection process should be noted, PP-R pipe in addition to some special pipes and fittings using other connection methods, such as metal pipes or water connection using the threaded inserts flange or other mechanical connections, the rest should be using hot melt connection, the integration of the pipe, no leakage points.

5. Special pipe with metal pipe installation connected to metal insert, not too much force, so as not to damage threaded fittings, resulting in junction leakage.

6. Heating pipes and fittings shall prevent over-heating, so thinner. Pipes deform in the pipe fittings.

7. When the hot-melt intubation and correction, rotation is strictly prohibited.

8. The operation should not have live fire, open flame is prohibited bake bend the pipe.

9. The PPR installation that is interrupted or completed at exposure must be temporarily closed well to avoid debris from entering.

- Q:How do you cut plastic tubes to size?

- To cut plastic tubes to size, you can use a few different methods depending on the thickness of the tube and the tools available. Some common techniques include using a hacksaw, a PVC pipe cutter, or a utility knife. It's important to measure and mark the desired length accurately before cutting, and to apply steady pressure while cutting to ensure a clean and straight cut.

- Q:Can plastic tubes be used for promotional or sample packaging?

- Yes, plastic tubes can be a great option for promotional or sample packaging. They are versatile, cost-effective, and can be easily customized with branding and labeling. Additionally, plastic tubes offer protection and convenience for packaging various products, making them suitable for promotional or sample purposes.

- Q:Long story short.....I would like to create my own pen from scratch. Where can I find the empty plastic tubes for the ink?

- I okorder okorder

- Q:How do plastic tubes compare to metal tubes in terms of durability?

- Plastic tubes typically have lower durability compared to metal tubes. While plastic tubes are lightweight and resistant to corrosion, they are more prone to cracking, breaking, or deforming under pressure or extreme temperatures. On the other hand, metal tubes are generally stronger, more rigid, and capable of withstanding higher pressures and temperatures, making them more durable in various applications.

- Q:Just basic plastic tubing for a project in school. An inch in diameter is fine (big enough for a marble to go through), and I'd need a few feet (enough to make 5 loops + an initial hill).I can't find any info on prices online. I've only found heavy duty stuff which are hundreds of dollars.Can I buy this type of stuff for cheap (how much on average?) at some sort of hardware store?

- vinyl tubing is pretty cheap - I would imagine around a dollar a foot or less for that size

- Q:Are plastic tubes suitable for pharmaceutical compounding?

- Yes, plastic tubes are suitable for pharmaceutical compounding.

- Q:Do plastic tubes have any UV resistance?

- Yes, plastic tubes can have UV resistance depending on the type of plastic they are made from. Some plastics, such as PVC, HDPE, and polycarbonate, are inherently UV resistant and can withstand prolonged exposure to sunlight without significant degradation. However, other plastics, like polyethylene and polypropylene, are more susceptible to UV damage and may require additional UV stabilizers or coatings to enhance their UV resistance.

- Q:are glass blood collection tubes are better than plastic s ?

- Not that I know of. Some of the benefits of using a plastic tube is that they are single-use, disposable, incineratable, and doesn't shatter when dropped, all lowering the risk of contamination.

- Q:How do plastic tubes compare to rubber tubes in terms of elasticity?

- Plastic tubes generally have lower elasticity compared to rubber tubes. While both materials exhibit some degree of flexibility, rubber tubes are known for their superior elasticity, allowing them to stretch and return to their original shape more easily. Plastic tubes, on the other hand, tend to be less stretchable and may not have the same level of elasticity as rubber tubes.

- Q:I remember having it as a kid and am wanting it for some stocking fillers! cant for the life of me remember what its called. have looked up all kinds of things on the net and not found a thing!

- I okorder /

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PPR Fitting Elbow with equal diameter on sales with Food Hygiene Regulations and Non-toxic

- Loading Port:

- Tianjin

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 11700 pc

- Supply Capability:

- 710000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords