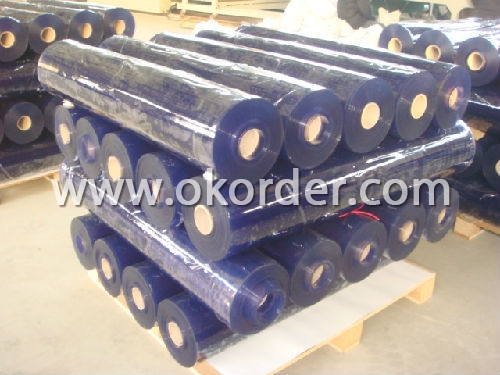

PVC Transparent Sheet Used for Desk Top

- Loading Port:

- TianJin Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20 Rolls roll

- Supply Capability:

- 15 Containers Per Month roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Factory-sale PVC Transparent Sheet Use For Desk Top

Flexible PVC sheet is widely applied for purpose of building and industrial partition ,swing doors,furniture protection,we can provide different dimensions and color solutions for customer's requirement of pvc sheet,which application temperature range from -15 ℃ to +50 ℃,different match of width,thickness and color bring out difference pvc sheet solutions and applications.

* width solution:

600mm/800mm/900mm/1000mm/1200mm/1300mm/1400mm/1500mm/1600mm/1800mm

* thickness solution:

1mm/1.5mm/2mm/3mm/4mm/5mm/6mm/7mm/10mm

Applications of Factory-sale PVC Transparent Sheet Use For Desk Top

I) these 1mm/1.5mm/2mm pvc sheet is ideal for application such as the partition of workshops and warehouses,printing,furniture protection,building insulation.

II) these 2mm/3mm pvc sheet is ideal to manufacture automatic roll-up doors,or if compatible,fully transparent light duty swing door panels for pedestrians.

III) these 4mm/5mm/6mm/7mm/10mm thickness sheet is best suitable for manufacturing of fully transparent light weight flexible doors,or the upper part of two color doors.

Package& Delivery of Factory-sale PVC Transparent Sheet Use For Desk Top

Wooden pallet,shirnk film according to custom requires.

Colors of Factory-sale PVC Transparent Sheet Use For Desk Top

clear: blue/yellow/nature

opaque: black/silver grey/milk white

- Q:How does the choice of plastic material impact the overall performance of home appliances?

- The choice of plastic material greatly impacts the overall performance of home appliances. Different types of plastics have varying properties such as strength, durability, heat resistance, and electrical conductivity. By selecting the appropriate plastic material, manufacturers can ensure that the appliance withstands the demands of daily use, operates efficiently, and remains safe for consumers. For example, using a high-temperature resistant plastic in a coffee maker can prevent warping or melting when exposed to hot liquids. Additionally, the choice of plastic can also influence the aesthetics and cost-effectiveness of the appliance. Overall, the selection of plastic material plays a crucial role in determining the performance, longevity, and overall user satisfaction of home appliances.

- Q:How does the plastic used in refrigerator doors affect energy efficiency?

- The plastic used in refrigerator doors can have an impact on energy efficiency. High-quality plastic with good insulation properties can help to reduce heat transfer between the inside and outside of the refrigerator, thus improving energy efficiency. On the other hand, low-quality or poorly insulated plastic can allow more heat to enter the fridge, requiring the compressor to work harder and consume more energy to maintain the desired temperature. Therefore, the type and quality of plastic used in refrigerator doors play a crucial role in determining the energy efficiency of the appliance.

- Q:Are there any specific disposal guidelines for plastic parts in home appliances?

- Yes, there are specific disposal guidelines for plastic parts in home appliances. It is generally recommended to check with your local waste management or recycling facility to determine the best method of disposal. In some areas, plastic parts may be accepted in recycling programs, while in others, they may need to be disposed of as regular household waste. It is important to follow these guidelines to ensure proper disposal and minimize environmental impact.

- Q:Can plastic parts in ovens and stoves withstand high heat?

- Yes, plastic parts in ovens and stoves can generally withstand high heat.

- Q:Are there any health concerns related to using plastic in home appliances?

- Yes, there are potential health concerns related to using plastic in home appliances. Some plastics contain harmful chemicals like bisphenol A (BPA) and phthalates, which can leach into food or beverages when heated or stored for a long time. These chemicals have been linked to various health issues, including hormonal imbalances, reproductive problems, and certain types of cancer. It is advisable to use appliances made from BPA-free or food-grade plastics and to minimize prolonged contact with hot plastics to reduce potential health risks.

- Q:Are there any concerns with using plastic in appliances that come in contact with food?

- Yes, there are concerns with using plastic in appliances that come in contact with food. Plastic can potentially leach harmful chemicals into the food, especially when exposed to high temperatures or acidic foods. This can pose health risks, particularly if these chemicals are ingested over a long period of time. It is advisable to choose appliances made from food-grade plastic or alternative materials, such as stainless steel or glass, to minimize the potential health hazards associated with plastic contact.

- Q:Can home appliance plastics be easily recycled at the end of their life?

- Yes, home appliance plastics can be easily recycled at the end of their life. Many recycling facilities accept and process these plastics, allowing them to be transformed into new products, reducing waste and environmental impact.

- Q:What are the considerations for using sustainable or eco-friendly plastics in home appliances?

- When using sustainable or eco-friendly plastics in home appliances, there are several important considerations. Firstly, the lifecycle of the plastic must be evaluated, including its production, use, and disposal. It should be made from renewable resources and have a minimal carbon footprint. Additionally, the durability and performance of the plastic should be assessed to ensure it can withstand the demands of an appliance. Compatibility with existing recycling systems is crucial to promote proper disposal and recycling. Finally, cost-effectiveness and availability of sustainable plastics should be considered to ensure their practicality and widespread adoption in home appliances.

- Q:Are there any concerns with using plastic in appliances that emit ultraviolet radiation?

- Yes, there are concerns with using plastic in appliances that emit ultraviolet radiation. Plastic materials may degrade or discolor when exposed to UV radiation over time. This can result in reduced durability, compromised aesthetics, and potential release of harmful chemicals. Additionally, some plastics may not effectively filter or block UV radiation, which could lead to harmful exposure for users or damage to surrounding objects. Therefore, careful consideration should be given to the selection and design of plastic materials used in such appliances to mitigate these concerns.

- Q:How do home appliance plastics contribute to the overall convenience of the appliance?

- Home appliance plastics contribute to the overall convenience of the appliance in several ways. Firstly, they enhance the durability and longevity of the appliance, ensuring it can withstand regular use and potential impacts. Secondly, plastics allow for lightweight construction, making the appliance easier to move and handle. Additionally, plastics enable manufacturers to design appliances with sleek and modern aesthetics, enhancing the overall appearance. Lastly, plastics provide insulation and resistance to heat and moisture, ensuring optimal performance and safety of the appliance.

1. Manufacturer Overview |

|

|---|---|

| Location | Hebei, China |

| Year Established | 1995 |

| Annual Output Value | Above US$ 50 Million |

| Main Markets | 15.00% Mid East 10.00% Northern Europe 10.00% North America 30.00% Eastern Asia 10.00% Africa 9.00% Eastern Europe 8.00% Southeast Asia 3.00% Oceania 3.00% Western Europe 2.00% Southern Europe |

| Company Certifications | ISO 9001 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Tianjin; Qingdao; Shagnhai; Guanghzou |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English; Chinese |

| b)Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High; Average |

Send your message to us

PVC Transparent Sheet Used for Desk Top

- Loading Port:

- TianJin Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20 Rolls roll

- Supply Capability:

- 15 Containers Per Month roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords