Refractory High Alumina Thermal Insulating Fire Brick 2015

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details for Refractory High Alumina Thermal Insulating Fire Brick 2015

| Place of Origin: | China (Mainland) | Shape: | Brick | Material: | Alumina Block |

| SiO2 Content (%): | international index | Al2O3 Content (%): | ≥48 | MgO Content (%): | 0 |

| CaO Content (%): | 0 | Refractoriness (Degree): | Common (1580°< Refractoriness< 1770°) | CrO Content (%): | 0 |

| SiC Content (%): | 0 | Model Number: | LG-1.0 | Brand Name: | |

| Sample: | Free | Fe2O3 %: | ≤2 | Bulk Density, g/cm3: | ≤1.0 g/cm3 |

| Cold crushing strength(Mpa): | ≥3.9 | temp linear change on reheating: | 1400 | Thermal conductivity /W.(m.k)-1: | ≤0.5 |

| size: | 230mm*114mm*65/75mm | HS code: | 6902200 |

Packaging & Delivery

| Packaging Details: | Packed on wooden pallets, with water-proof cover, all measurements of each case is 1050mm*1050mm*1050mm. We will pack the goods according to your requirement. |

| Delivery Detail: | 10~30 days after receiving your payment |

refractory lightweight high alumina thermal insulating fire brick

Product Description

Refractory lightweight high alumina thermal insulating fire brick is made out of a naturally-occurring material known as bauxite. This material includes aluminum hydroxide, which is what gives the bricks such great warmth resistance. The bricks also include kaolinitic clays, which are roasted to create an unique combination including mullite and also synthetic alumina. This is where the name “high alumina” stems from.

Features

1.High-temperature endurable .

2.Good thermal shock resistance .

3.High cold crushing strength.

4.Good resistance to abrasion and corrosion.

5.Good thermal spalling resistance.

6.High mechanical strength.

7.Good volume stability at high temperature.

Application

1.General use in heat containment unit form temperature 1500-2000°C.

2.Resistant to highest temperature for steelmaking operations such as ladle applications, sidewall, roofs, burner blocks, anchor brick for reheating furnaces and many other areas.

3.transition and cooling zones of rotary cement kilns, lime kilns , etc.

4.lower sidewall and bottom of aluminum refining,melting furnaces ,etc.

Technical Data

Description of parameters |

Index of high alumina lightweight fire brick | ||||||

LG- 1.0 | LG-0.9 | LG-0.8 | LG-0.7 | LG-0.6 | LG-0.5 | LG-0.4 | |

AL2O3 % | ≥48 | ||||||

Fe2O3 % | ≤2.0 | ||||||

Bulk Density, g/cm3 | ≤1.0 | ≤0.9 | ≤0.8 | ≤0.7 | ≤0.6 | ≤0.5 | ≤0.4 |

Cold Crushing Strength MPa | ≥3.9 | ≥3.4 | ≥2.9 | ≥2.5 | ≥2.0 | ≥1.5 | ≥0.8 |

Test temp linear change within 2%on reheating | 1400 | 1400 | 1400 | 1350 | 1350 | 1250 | 1250 |

Thermal conductivity /W.(m.k)-1 | ≤0.5 | ≤0.45 | ≤0.35 | ≤0.35 | ≤0.30 | ≤0.25 | ≤0.20 |

Packaging & Shipping

1. Strong packing will protect the goods from any possible damage during transit.

2. Solid packing and overall stuffing can prevent the cases from vibration and jarring.

3. We must take necessary precaution that the packing can protect the goods from pilferage or rain.

4. l can confirm that we take every possible precaution to ensure that our products reach our customers all over the world in prime conditon.

Our Services

1.We will reply to you immediately, if you have any question.

2.We can provide free samples for you.

3.we have all kinds of fire bricks ,for example,high alumina brick ,fireclay brick, corundum brick, refractory ball, allotypic brick, lightweight brick and so on. We can offer you products of a wide range of specifications.

Why choose us

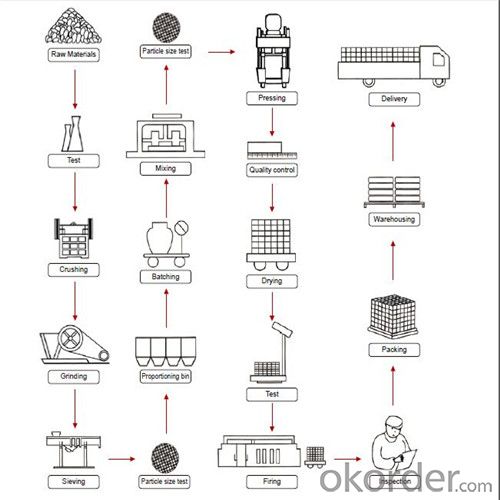

1.We are professional manufacturer of refractory brick and had been in this line for more than 20 years .

2.Our products quality will be guaranteed . We have our own technical team to test the products before delivery.

3.Competitive prices based on same quality. Guarantee samples quality same as mass production quality.

4.Adhering to the business philosophy "mutual trust, mutual benefit, mutual profit, faith oriented".

5.We can according to your requirements to produce your order and OEM/ODM service is available.

6. Products are inspected through SGS and BV etc and accord with the international standard.

7.Your inquiry related to our products or prices will be replied in a timely manner.

8. We provide the best after sales service.

- Q:Are insulating fire bricks resistant to thermal fatigue?

- Yes, insulating fire bricks are generally resistant to thermal fatigue due to their ability to withstand repeated heating and cooling cycles without significant damage or deterioration. Their high thermal shock resistance and low thermal conductivity make them ideal for applications where thermal cycling occurs frequently.

- Q:Are insulating fire bricks suitable for use in the construction of drying ovens?

- Yes, insulating fire bricks are suitable for use in the construction of drying ovens. They have excellent thermal insulation properties, which helps to retain heat and prevent heat loss during the drying process. Additionally, insulating fire bricks can withstand high temperatures and have good resistance to thermal shocks, making them a reliable choice for drying oven construction.

- Q:Are insulating fire bricks resistant to erosion from flowing gases or liquids?

- Generally, insulating fire bricks exhibit resistance to erosion caused by flowing gases or liquids. These bricks are designed to possess excellent thermal insulation properties and the ability to withstand high temperatures, making them suitable for a wide range of industrial uses. The bricks are constructed from lightweight refractory materials with low porosity, which aids in minimizing the infiltration of gases and liquids. Moreover, insulating fire bricks often exhibit chemical inertness, further enhancing their erosion resistance. However, it is crucial to acknowledge that the erosion resistance of these bricks may vary depending on factors such as composition, manufacturing process, and the characteristics of the flowing gases or liquids. Therefore, it is advisable to consult the manufacturer or a qualified expert to assess the suitability of insulating fire bricks for a specific application.

- Q:Do insulating fire bricks require any maintenance?

- Insulating fire bricks, also known as refractory bricks, are designed to withstand high temperatures and provide excellent insulation properties. One of the advantages of insulating fire bricks is that they require very little maintenance. These bricks are made from special materials that have high resistance to heat and thermal shock. As a result, they do not crack or break easily, reducing the need for frequent repairs or replacements. However, like any other material, insulating fire bricks can accumulate dust or debris over time. Regular cleaning is recommended to maintain their effectiveness and prolong their lifespan. This can be done by using a soft brush or vacuum cleaner to remove any loose particles. In addition, it is important to inspect the bricks periodically for any signs of damage, such as cracks or erosion. If any issues are identified, they should be addressed promptly to prevent further deterioration. Overall, while insulating fire bricks do not require extensive maintenance, regular cleaning and inspection are essential to ensure their optimal performance and longevity.

- Q:Do insulating fire bricks have good mechanical strength?

- Yes, insulating fire bricks have good mechanical strength. They are specifically designed to withstand high temperatures and provide excellent thermal insulation while maintaining their structural integrity.

- Q:Can insulating fire bricks be used in the construction of thermal insulation floors?

- Yes, insulating fire bricks can be used in the construction of thermal insulation floors. Insulating fire bricks are specially designed to have low thermal conductivity, which means they can effectively prevent the transfer of heat. This makes them an excellent choice for thermal insulation applications, including floors. By using insulating fire bricks in the construction of thermal insulation floors, the heat loss from the floor can be significantly reduced, leading to improved energy efficiency and cost savings. Additionally, insulating fire bricks are lightweight and easy to install, making them a practical choice for construction projects. Overall, insulating fire bricks are a suitable and effective option for incorporating thermal insulation into floors.

- Q:Are insulating fire bricks suitable for insulation in gas turbines?

- Yes, insulating fire bricks are suitable for insulation in gas turbines. They have excellent insulating properties and can withstand high temperatures, making them an ideal choice for protecting and insulating the components of gas turbines.

- Q:Are insulating fire bricks resistant to carbon monoxide?

- Indeed, insulating fire bricks demonstrate a remarkable resistance to carbon monoxide. Tailored for enduring extreme temperatures, these bricks find common application in environments where they are likely to encounter both intense heat and corrosive agents, including carbon monoxide. The insulating nature of these bricks bestows upon them an exceptional ability to impede heat transfer, ensuring their structural integrity remains intact even in the presence of carbon monoxide and other combustible gases. This resistance to carbon monoxide renders insulating fire bricks a stellar choice for various settings like furnaces, kilns, and other high-temperature surroundings where the potential for carbon monoxide exposure looms.

- Q:Can insulating fire bricks be used in heat exchangers?

- Yes, insulating fire bricks can be used in heat exchangers. These bricks are designed to have excellent thermal insulation properties, making them suitable for applications where heat needs to be contained or transferred efficiently. Heat exchangers rely on the efficient transfer of thermal energy, and insulating fire bricks can help in reducing heat loss or gain in these systems, improving their overall efficiency.

- Q:Can insulating fire bricks be used in the construction of combustion flues?

- Yes, insulating fire bricks can be used in the construction of combustion flues. Insulating fire bricks are designed to withstand high temperatures and are often used to line combustion chambers and flues to provide insulation and prevent heat loss. They have excellent thermal properties, making them suitable for this purpose.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Refractory High Alumina Thermal Insulating Fire Brick 2015

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords