Refractory Light Brick Thermal Insulating Fire Brick

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Refractory Light Brick Thermal Insulating Fire Brick

High alumina insulating fire brick is a kind of insulation material adopting organic matter as ignition loss substance in order to increase the porosity of refractory, which has such advantages as high porosity, small volume density, good insulation effect, high mechanical intensity, small thermal conductivity and long service life. For various industrial kilns & furnaces, it is a kind of essential refractory for energy saving and temperature preservation.

This series of High Alumina Insulating Fire Brick are made of selected high alumina bauxite, kaolin caly, hollow microsphere as the mian material.By shaping at high pressure and sintering at high temperature.

Product Applications:

High alumina insulating fire brick are ideal for use in the below applications

Building materials for blast furnace

Building materials for hot-blast stove

Building materials for coke oven

Building materials for steel making furnace

For construction material in steel industry

For ladle

Product Advantages:

CNBM has success in its High alumina insulating fire brick due to their cost-effectiveness and excellent insulating properties. The refractoriness of magnesia chrome bricks are more than 2000°C, and the refractory under load is a above 1550°C.Good steady volume in high temperature, the performance of meeting sudden cold and sudden hot is better than magnesia bricks.

Main Product Features:

Excellent thermal stability

High refractoriness under load

Chemical stability and anti-corrision

Small high temperature creep rate

Excellent thermal shock resistance

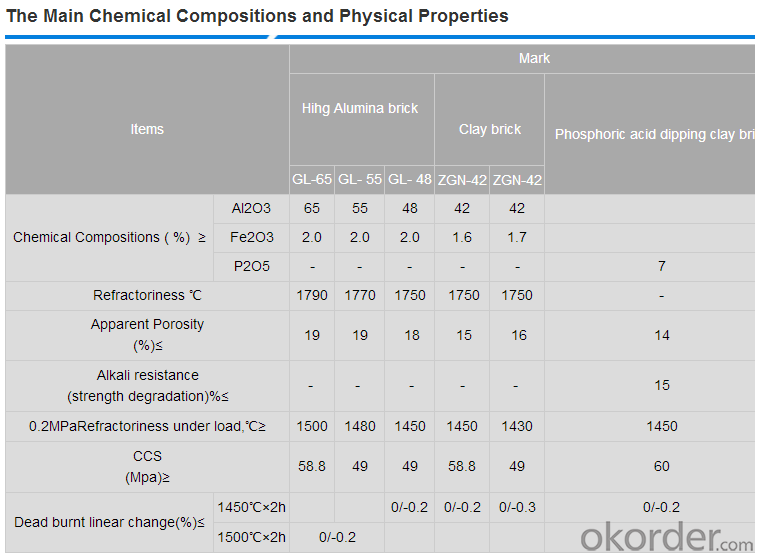

Product Specifications:

FAQ:

Q1: Are you a manufacture or trader?

A1: Factory+trade (mainly for manufacturing, also do some business of related products).

Q2: What's the MOQ of trial order?

A2: No limit,We can offer the best suggestions and solutions according to your requirements.

Q3: After an order is confirmed,when to deliver?

A3: According to your order quantity, normally, 15-25 days after deposit received.

Q4: Is your company accept customization?

A4: We have our own factories and excellent technical team, and we accept OEM service.

Product Picture

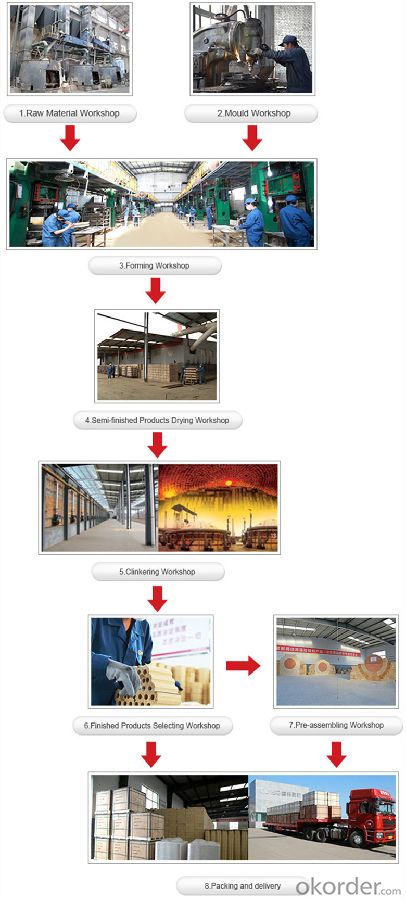

Produce Processing

- Q:How thick are insulating fire bricks?

- Insulating fire bricks typically have a thickness ranging from 2.5 to 4 inches (6.35 to 10.16 cm). The specific thickness depends on the manufacturer and the intended application of the bricks. These bricks are designed to withstand high temperatures and provide excellent insulation, making them suitable for use in kilns, furnaces, and other high-temperature environments.

- Q:Can insulating fire bricks be used in the construction of foundry furnaces?

- Yes, insulating fire bricks can be used in the construction of foundry furnaces. These bricks are made from lightweight refractory materials that have excellent insulation properties, allowing them to withstand high temperatures and retain heat efficiently. They are commonly used in foundry furnaces to line the walls, floor, and roof, helping to minimize heat loss and improve energy efficiency.

- Q:Can insulating fire bricks be used in the construction of lime production linings?

- Yes, insulating fire bricks can be used in the construction of lime production linings. Insulating fire bricks are designed to have low thermal conductivity, which makes them excellent for applications where heat insulation is required. In lime production, high temperatures are required for the calcination process. Using insulating fire bricks in the construction of lime production linings helps to reduce heat loss and improve energy efficiency. Additionally, insulating fire bricks are lightweight and easy to handle, which makes them suitable for lining various parts of lime kilns and other equipment used in the lime production process. Overall, using insulating fire bricks in lime production linings can help to optimize the production process and improve the overall performance of lime production facilities.

- Q:Are insulating fire bricks suitable for use in thermal shock applications?

- Insulating fire bricks prove to be appropriate for thermal shock applications. Specifically designed to endure sudden temperature variations without any cracks or breaks, they possess a low thermal conductivity and a high thermal resistance, making them an optimal choice for concerns related to thermal shock. Comprised of lightweight refractory materials, these bricks often contain a significant amount of alumina or silica, which grants them exceptional thermal stability and resistance to thermal shock. Their utilization can be seen in a wide range of high-temperature scenarios, including kilns, furnaces, and fireplaces, where they face extreme temperature fluctuations. Ultimately, insulating fire bricks demonstrate their suitability for thermal shock applications by effectively enduring abrupt temperature changes and maintaining their structural integrity.

- Q:Can insulating fire bricks be used as a refractory material?

- Yes, insulating fire bricks can be used as a refractory material. Insulating fire bricks have excellent thermal insulation properties and can withstand high temperatures, making them suitable for use in various refractory applications such as furnaces, kilns, and insulation linings.

- Q:Can insulating fire bricks be used in the construction of smelter crucibles?

- Yes, insulating fire bricks can be used in the construction of smelter crucibles. Insulating fire bricks are made from materials that can withstand high temperatures, making them suitable for use in smelting operations. These bricks have low thermal conductivity, which helps to retain heat and prevent excessive heat loss from the smelter crucible. This makes them ideal for creating a well-insulated and efficient crucible that can withstand the intense heat and thermal shock associated with smelting processes. Additionally, insulating fire bricks are lightweight and easy to shape, allowing for convenient construction and customization of the crucible design. Overall, using insulating fire bricks in the construction of smelter crucibles can help to improve the thermal efficiency and durability of the crucible, leading to more efficient and effective smelting operations.

- Q:Are insulating fire bricks resistant to oil and gas?

- Yes, insulating fire bricks are generally resistant to oil and gas. These bricks are designed to withstand high temperatures and are commonly used in applications where they may come into contact with oil and gas, such as furnaces and kilns. However, it is important to note that the specific type and composition of the fire bricks can affect their resistance, so it is always recommended to consult the manufacturer's specifications for detailed information.

- Q:Are insulating fire bricks resistant to thermal bridging?

- Yes, insulating fire bricks are resistant to thermal bridging. Thermal bridging occurs when there is a direct path for heat to flow through a material, bypassing the insulation. Insulating fire bricks are designed to minimize this by having low thermal conductivity, which means they are not effective at conducting heat. This helps to maintain a consistent temperature on both sides of the brick, preventing thermal bridging and improving the overall insulation performance.

- Q:What is the typical thermal expansion coefficient of an insulating fire brick?

- The thermal expansion coefficient of an insulating fire brick can differ depending on its material composition and manufacturing process. However, as a general rule, insulating fire bricks have a lower thermal expansion coefficient compared to other brick types. This coefficient measures the degree to which a material expands or contracts when exposed to temperature changes. Typically, the thermal expansion coefficient of an insulating fire brick falls within the range of 5 to 8 x 10^-6 per degree Celsius (5-8 μm/m°C). In simpler terms, for every one degree Celsius increase in temperature, the insulating fire brick expands by approximately 5 to 8 micrometers per meter of length. The low thermal expansion coefficient of insulating fire bricks is highly desirable in applications where there are frequent and significant temperature fluctuations. This characteristic helps minimize the risk of thermal stress and cracking, ensuring that the insulating fire brick remains durable and performs well in high-temperature environments. It should be noted that the specific thermal expansion coefficient may vary depending on factors such as the manufacturer, type of insulating fire brick, and intended temperature range. Therefore, it is advisable to consult the manufacturer's specifications or technical data sheets for precise and detailed information regarding the thermal expansion coefficient of a particular insulating fire brick.

- Q:Can insulating fire bricks be cut or shaped to fit different spaces?

- Indeed, it is possible to cut or shape insulating fire bricks to suit various spaces. These bricks are crafted from lightweight materials, enabling effortless customization using ordinary tools like saws, knives, or rasps. Consequently, they can be perfectly tailored to fit fireplaces, kilns, furnaces, and other high-temperature settings. Nevertheless, it must be emphasized that caution must be exercised while cutting or shaping insulating fire bricks, as they may generate dust or debris.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Refractory Light Brick Thermal Insulating Fire Brick

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords