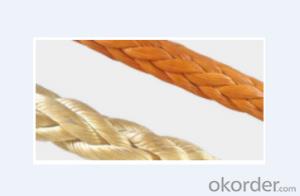

Textile Sling TYPE R02 (PROTECTION TYPE)

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0 pc

- Supply Capability:

- 1000 pc/month

- Option:

- TYPE R02

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Textile Sling

Textile sling factory is the largest base for lifting belts in the world with the production capacity over 20000t.We have thousands of manufacturing equipments, including Muller weaving machines from Switzerland,dyeing machines from Germany and automatic sewing machines form Japan,etc.

The main products are: webbing sling, round sling, ratchet strap, assembly sling, mooring rope and traction rope, according to different using environments, different materials would be used, such as polyester, polypropylene, nylon, Kevlar and HMPE (high molecular weight polyethylene material). We are able to manufacture special slings such as high-strength type, flame retardant type, anti - slip type, wear - resistant type, acid and alkali resistant type, high temperature resistant type, fluorescent type, optical inspection type and oil and water resistant type sling.

With characteristics like soft, light, no harm to the cargo, safety, long life and so on.

Product usage : Textile slings are widely used for lifting, pulling, bundling, fixed and other operations in machining, port handling, marine engineering, ship, electric power, transportation, aerospace and other fields.

Achievements in scientific research:

In 1997, we drafted out the industrial standard for textile slings together with Beijing Hoisting Machinery Institute: JB/T8521-1997, which makes historic progress for the Chinese textile sling industry.

In 2007, we revised JB/T8521.1-2007 “Textile Sling – Safety - Part 1: Common use webbing sling” and JB/T 8521.2-2007 “Textile Sling - Safety - Part 2: Common use round sling”.

In 2009, we edited GB/T 23914.2-2009 “Road vehicle mounted fixtures – Safety – part 2: Synthetic ratchet strap assemblies”, participated in writing TB/T 3123.11-2009 “Rescue devices for railway accidents - part 11: high-performance textile sling”.

In 2014, we participated in writing GB/T 30667-2014 “Polyester and polyolefin dual Fiber rope” and GB/T 30668-2014 “8 strands, 12 strands and multiflament braided Ultra high molecular weight polyethylene fiber rope”.

- Q:What are the specifications for the length, length, and method of operation of the wire rope?

- The use of wire rope in the atmospheric environment, mainly caused by the failure of wire rope is fretting fatigue, at present, the wire rope for the first time in the field of fretting fatigue control measures is the phosphating coating steel wire rope patent technology production, steel wire after manganese phosphating or zinc manganese treatment, wear resistance, enhance the surface of steel wire that is not easy to wear and corrosion resistance of the fatigue life is greatly improved

- Q:What are the dangerous sections of the crane hook?

- The sling tension A-A section on the one hand, the hook has straightened trend; also by the effect of bending moment on the other hand. Because the moment in this section, the bending stress is maximum, this section is a dangerous section.

- Q:What's the catch?

- The type of slings 1. slings are mainly metal slings and synthetic fiber slings in two main categories. 2. metal slings are mainly wire ropes, slings, chains, slings and so on. 3. synthetic fiber slings are mainly made of nylon, polypropylene, polyester, high-strength and high modulus polyethylene fiber for rope and belt slings.

- Q:How to choose the right sling?

- Commonly used slings and slings are lifting belts, lifting chains and wire ropes. Slings and slings must be matched with lifting equipment, such as 5 tons or 10 tons. Cranes shall be marked with maximum lifting weight. Lifting belt will not damage the hoisting object but poor wear resistance, easy maintenance but large weight lifting chain, rope buckle range but the broken wire after easily scratch objects and operators, each have advantages and disadvantages, to meet their own needs is the best lifting.Phosphating coating of steel wire rope production technology patent, give priority to the use of manganese or zinc manganese phosphating, and smooth steel wire rope production process comparison, just increase the steel wire wear phosphating process, phosphating of steel wire surface after the abrasion resistance and corrosion resistance is greatly improved, the use of direct phosphating steel wire twisting steel wire rope (steel wire after phosphating not drawing). The fatigue test data show that the fatigue life of the phosphating coating of steel wire rope is about 3-4 times the same structure of plain steel wire rope, wire rope is 2-3 times of imports (laboratory comparable conditions) with the research on the wear resistance of phosphating, and greatly enhance the possibility of. Manganese phosphating is wear resistant phosphating, which can completely solve the wear problem in the use of wire rope.

- Q:What is the line on the train for?

- The catenary provides 25 thousand volt power frequency alternating current for the locomotive, according to the locomotive model difference, adopts the direct step-down, the frequency conversion power supply or the AC and DC conversion power supply, this is mainly for the speed regulation convenience.

- Q:What's the sling for a movie?

- Now the movie also used the wire, but the rope is made by thin steel wire, so as not to betray. WIA, commonly known as wire.

- Q:What are the precautions for rigging in hoisting works?

- The sling shall not be allowed to repair or reprocess itself (welding, heating, heat treatment, surface chemical treatment). If such treatment must be carried out, it shall be sent back to the original manufacturer or under the guidance of the experts of the original factory.

- Q:How much is the crane arm of the tower from the residential building recently?

- No aluminum conductor or steel shall be used as grounding or ground wire for the installation of tower cranes. A bolted wire must have an end. Grounding is mainly made up of the following three ways:1. the grounding body adopts a regular grounding pile, or a 33*4.5 long 1.5m steel tube, or a 70*70 long 1.5m angle steel.2. the floor is made of steel plates or other metal plates with an area of 1 square meters. The ground is deep from the ground 1.5m.3. a copper conductor with a cross-section of not less than 28 mm or a steel conductor with a cross section of not less than 50 mm is buried in the slot and its embedment length is determined by the grounding resistance.In the above three ways, the grounding body leads the copper conductor, the sectional area shall be no less than 25, if the soil is not conductive, the sodium chloride (salt) can be embedded in the soil. Then irrigation. For walking crane, each rail must be grounded, and the two tracks are connected by wires. Electrical connections should also be made between the two rails, with a resistance of no more than 4.

- Q:What is the influence of lifting angle on rigging?

- The vertical lifting is the best scheme for lifting. The smaller the angle between the sling and the vertical is, the greater the angle is, the greater the force the sling will bear. The sling will be easily broken off, which will lead to an accident, which is for reference only

- Q:Is the sling the same thing as the rigging?

- As for your concept, I have also struggled with it before. I also consulted the professionals who were applying the rigging.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Textile Sling TYPE R02 (PROTECTION TYPE)

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0 pc

- Supply Capability:

- 1000 pc/month

- Option:

- TYPE R02

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches