Tripod & Beam Clamp for building construction

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Steel Prop & Tripod & Beam Clamp

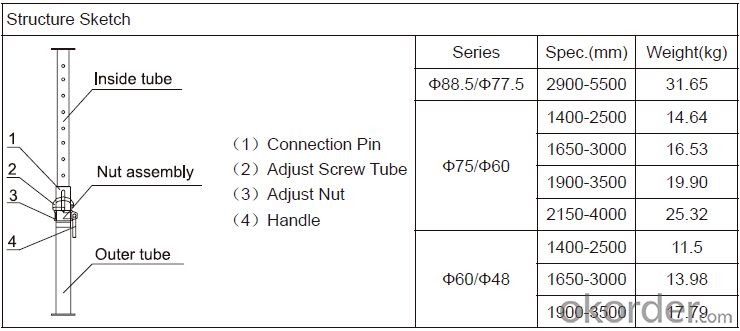

(1) Steel prop is a vertical support system widely used in construction.

Characteristics:

◆ Simple & flexible structure

◆ Easy & fast operation

◆ Economical efficiency

◆ Easy storage and transportation

◆ Reasonable load-bearing capacity

(2) Tripod is always used as support for steel prop.

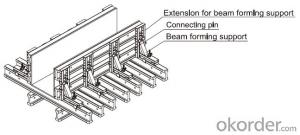

(3) The beam clamp is a technical instrument for supporting beam formwork

which makes conventional beam formwork simple, and increases the construction

efficiency.

Characteristics:

◆ Flexible structure

◆ Optimum design proposal

- Q:Can steel props be used for supporting temporary bridges during construction?

- Yes, steel props can be used for supporting temporary bridges during construction. Steel props are commonly used in construction projects to provide temporary support and stability to structures. They are strong, durable, and adjustable, making them suitable for various applications, including supporting temporary bridges.

- Q:Are steel props suitable for supporting temporary stairs or ramps?

- Yes, steel props are suitable for supporting temporary stairs or ramps. Steel props are known for their high load-bearing capacity and stability, making them ideal for providing structural support to temporary structures like stairs and ramps.

- Q:Can steel props be used for temporary support in railway platform construction?

- Steel props are indeed suitable for temporary support in the construction of railway platforms. They are widely employed in construction endeavors to furnish temporary support for various structures, including the building of railway platforms. These props possess adjustability, allowing them to be extended or retracted as required to provide the vital support and stability. Typically crafted from high-strength steel, they exhibit the necessary robustness to endure the weight and load demands of railway platforms. Moreover, steel props can be swiftly and effortlessly installed and removed, rendering them a pragmatic option for temporary support during railway platform construction.

- Q:What is the average cost of a steel prop?

- The average cost of a steel prop can vary depending on factors such as size, quality, and location. However, generally speaking, the average cost for a standard steel prop can range from $30 to $80.

- Q:Can steel props be used in the construction of skyscrapers or tall buildings?

- Yes, steel props can be used in the construction of skyscrapers or tall buildings. Steel props provide temporary support to the structure during construction, allowing for the safe installation of floors and beams at various heights. These props are strong, durable, and adjustable, making them suitable for supporting the weight and load of tall structures.

- Q:How do you ensure proper load transfer when using steel props on soft or weak soils?

- To ensure proper load transfer when using steel props on soft or weak soils, there are several measures that can be taken: 1. Soil investigation: Conduct a thorough soil investigation to determine the properties and characteristics of the soil. This includes identifying its strength, compressibility, and load-bearing capacity. This information will help in determining the appropriate load-bearing capacity of the steel props. 2. Proper prop selection: Select steel props with adequate load-bearing capacity that can effectively distribute the load to the weak or soft soil. This requires considering the maximum expected load, the depth of the soil, and the specific conditions of the site. 3. Spacing and positioning: Determine the correct spacing and positioning of the steel props to ensure even load distribution. This may involve using additional props or increasing their density in areas with weaker soils. 4. Base support: Provide sufficient support at the base of the props to prevent sinking or tilting. This can be achieved by using steel plates or timber boards to spread the load over a larger area and reduce the pressure on the weak soil. 5. Ground improvement techniques: Depending on the severity of the soil's weakness, ground improvement techniques may be required to enhance load transfer. These techniques can include soil stabilization methods such as compaction, grouting, or the use of geosynthetic materials. 6. Monitoring: Regularly monitor the performance of the steel props during construction to ensure they are effectively transferring the load. This can involve measuring the settlement, deflection, or any signs of instability, and taking appropriate remedial actions if necessary. It is important to note that the above measures serve as general guidelines, and the specific approach should be tailored to the individual site conditions and project requirements. Consulting with an experienced geotechnical engineer or structural engineer is recommended to ensure proper load transfer and overall stability of the structure.

- Q:Are steel props commonly used in industrial construction projects?

- Yes, steel props are commonly used in industrial construction projects. They provide temporary support for structures during construction, allowing for safe and efficient work. Steel props are strong, durable, and adjustable, making them ideal for various construction applications.

- Q:How do you ensure stability when using multiple steel props?

- To ensure stability when using multiple steel props, there are a few key steps that can be taken. Firstly, it is important to properly position and align the props so that they evenly distribute the load. This involves ensuring that the props are placed at regular intervals and at appropriate angles to support the structure effectively. Secondly, using additional bracing and cross supports can greatly enhance the stability of the props. These supports can be placed diagonally between the props to provide extra reinforcement and prevent any potential swaying or collapsing. Additionally, regular inspection and maintenance of the props is crucial. Any signs of wear, damage, or instability should be addressed immediately, and any faulty props should be replaced promptly. Lastly, following safety guidelines and adhering to weight limits is essential. Overloading the props can compromise their stability, so it is important to know the maximum weight capacity of each prop and never exceed it. By implementing these measures, stability can be ensured when using multiple steel props, minimizing the risk of accidents or structural failures.

- Q:Can steel props be used in the installation of heavy machinery?

- Yes, steel props can be used in the installation of heavy machinery. Steel props are sturdy and provide strong support, making them suitable for handling the weight and ensuring stability during the installation process.

- Q:What are the common load testing methods for steel props?

- Steel props undergo various load testing methods to assess their strength and structural integrity. These methods, widely utilized, include: 1. Static Load Testing: By employing hydraulic jacks or weights, a predetermined static load is gradually applied to the steel prop. The prop's deflection and deformation are closely monitored until the desired testing load is reached. This test aids in determining the prop's maximum load capacity and deformation characteristics under static conditions. 2. Proof Load Testing: A load higher than the expected working load is applied to the steel prop in this method. The prop endures this load for a specified duration to ensure it can withstand the intended working load without permanent deformation or failure. After the test, a thorough inspection is conducted to assess the prop's condition and suitability for use. 3. Ultimate Load Testing: This testing method involves subjecting the steel prop to an excessive load until it reaches its breaking point. The objective is to ascertain the maximum load the prop can withstand before failure, providing valuable information about its ultimate strength and safety factor. 4. Dynamic Load Testing: Real-life dynamic loads, like vibration or impact, are simulated on the steel prop in this method. The prop experiences repetitive loading cycles, and its response to these dynamic loads is measured. This test aids in evaluating the prop's fatigue resistance and durability under dynamic conditions. 5. Non-Destructive Testing (NDT): To inspect steel props without causing damage, NDT techniques like ultrasonic testing, magnetic particle testing, or radiography are frequently used. These methods can detect flaws, cracks, or imperfections in the material that may compromise the prop's load-bearing capacity. It is crucial to bear in mind that load testing methods may differ depending on the specific requirements and standards of the industry or project. Consulting relevant codes, standards, or structural engineers is essential to determine the appropriate load testing method for steel props in a particular context.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Tripod & Beam Clamp for building construction

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Hot Searches