Trustable Cuplock Scaffolding System with Best Prices

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 30000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Ring-lock Scaffolding

It can be widely used for industrial and civil construction and maintenance, such as workshop, large gymnasium, conference& exhibition center conversation, billboard, market, dock, tunnel, subways, etc. used for mobile working platform installation of electrical & mechanical engineering, ship repair and other decoration engineering, for building temporary stand ,with simple roof frame, frame-connected Scaffolding can from temporary dormitory, depot and work shed.

2.Main Features of Cup-lock Scaffolding

Each Cup-lock is welded on post every 0.6m. Choose step pitch based on mechanical requirementsWhen installing the scaffolding, insert ledger connector into the pole of the cup-lock, then hammer ledger connector to finish fastening.The more load, the more reliable fasten.Cup-lock Scaffolding has no special retaining member and no active parts. It’s easy and convenient to operation with integral low costs.

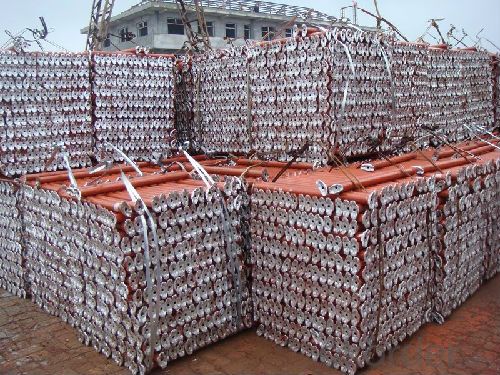

3.Cup-lock Scaffolding Images

4.Cup-lock Scaffolding Specification

A support system for construction, owns advantages of both cup-lock scaffolding and shoring tower.It is in the development direction of new type scaffolding.

It is widely used in buildings, bridges, tunnels etc.

5.FAQ OF Cup-lock Scaffolding

What about the package and shipping time?

Packing: As Customer's Requirements

Shipping: We have various shipping ways for our customers, such as express which including TNT, DHL, FEDEX, UPS, EMS, etc. ; by air/ sea, and we

are VIP of these express.

Shipping time:

Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days.

Other mass qty of Ring-lock Scaffolding, we send them out by sea or by air to sea port or air port to save some shipping freight for our customers. By ocean, it may need 45~60days, by air, it may need 25~40days.

- Q:How do steel tube couplers prevent slippage or loosening of scaffolding connections over time?

- To prevent slippage or loosening of scaffolding connections over time, specific design features are incorporated into steel tube couplers. These couplers are composed of a cylindrical body equipped with internal teeth or gripping mechanisms that effectively hold the tubes together. A primary method of preventing slippage is achieved by ensuring a tight fit between the tubes. By tightening the coupler, the tubes are compressed together, creating a strong connection that leaves no room for movement or slippage. This tight fit guarantees that the connection remains secure, even when subjected to heavy loads or vibrations. Furthermore, steel tube couplers often incorporate a locking mechanism to enhance the stability of the connection. This can take the form of a bolt or a pin that is inserted through the body of the coupler, effectively locking the tubes in place. This additional measure provides an extra layer of security, preventing any potential slippage or loosening over time. Moreover, steel tube couplers are typically constructed using high-quality and durable steel materials. These materials are renowned for their strength and resistance to wear and tear. The durability of the couplers ensures that they can withstand the forces and pressures exerted on scaffolding connections over time, without compromising their performance. In conclusion, the prevention of slippage or loosening in scaffolding connections is achieved by steel tube couplers through the implementation of a tight fit between the tubes, the incorporation of a locking mechanism, and the utilization of durable materials. These features work in harmony to establish a stable and secure connection that can withstand the demands of construction, thus ensuring the safety of workers.

- Q:How do steel tube couplers compare to other types of scaffolding connectors in terms of structural integrity?

- When it comes to structural integrity, steel tube couplers are highly regarded as one of the most effective and reliable types of scaffolding connectors. These connectors are specifically designed to securely connect steel tubes, creating a strong and stable scaffolding structure. Compared to other types of scaffolding connectors like wedge and pin connectors or clamp-on connectors, steel tube couplers offer unmatched strength and durability. They are typically manufactured using high-quality steel, ensuring their ability to withstand heavy loads and adverse weather conditions. The design of steel tube couplers allows for a tight and secure fit around the steel tubes, minimizing the risk of movement or slippage. This guarantees that the scaffolding remains stable and safe for workers to carry out their tasks. Furthermore, steel tube couplers undergo rigorous testing and quality control measures to ensure compliance with industry standards and regulations. Manufacturers conduct various tests, such as load testing and stress analysis, to ensure that these connectors can withstand the forces and loads they are designed to bear. In addition, steel tube couplers offer versatility in their application. They can be used in different scaffolding configurations, including straight runs, angles, and corners, providing flexibility in scaffolding design. Overall, the construction industry widely recognizes and prefers steel tube couplers for their exceptional structural integrity. Their strength, durability, secure fit, and versatility make them a reliable choice for various scaffolding applications.

- Q:Are steel tube couplers suitable for scaffolding projects involving delicate or sensitive materials?

- No, steel tube couplers may not be suitable for scaffolding projects involving delicate or sensitive materials. Steel tube couplers are commonly used in construction projects due to their strength and durability, but they may not provide the level of protection or gentleness required for delicate or sensitive materials. Other scaffolding systems or specialized couplers may be more appropriate to ensure the safety and integrity of such materials.

- Q:Are steel tube couplers adjustable or fixed in position once installed?

- Steel tube couplers are typically fixed in position once they are installed.

- Q:Can steel tube couplers be used in scaffolding projects with limited access to safety harness attachment points?

- Yes, steel tube couplers can be used in scaffolding projects with limited access to safety harness attachment points. Steel tube couplers are commonly used in scaffolding systems to connect and secure scaffold tubes together, providing structural stability and support. These couplers are designed to safely join tubes at various angles and configurations, allowing for the creation of a sturdy scaffolding structure. In situations where there is limited access to safety harness attachment points, alternative methods can be employed to ensure the safety of workers. One option is to use fixed anchor points or tie-off points that are securely attached to the scaffold structure. These anchor points can be strategically placed at intervals along the scaffolding to provide workers with suitable locations to attach their safety harnesses. Another option is to use specialized scaffolding accessories such as adjustable beam clamps or beam anchors, which can be installed on horizontal or vertical beams. These accessories can serve as additional attachment points for safety harnesses, offering workers more flexibility in finding suitable locations to secure themselves. It is crucial to prioritize safety in scaffolding projects, and adherence to safety regulations and guidelines is of utmost importance. While steel tube couplers can be used effectively in scaffolding projects with limited access to safety harness attachment points, it is essential to consult with experienced professionals and follow industry best practices to ensure the safety of workers at all times.

- Q:What is the typical lifespan of steel tube couplers in scaffolding applications?

- The lifespan of steel tube couplers in scaffolding applications can vary based on multiple factors. Factors such as the quality of the couplers, how often and intensely they are used, and the level of maintenance and care they receive can all impact their lifespan. Typically, when high-quality steel tube couplers are used in standard scaffolding applications, they can last for several years. By regularly inspecting, maintaining, and properly caring for them, they can withstand the demands of construction sites and provide reliable support for extended periods. However, it is important to be aware that certain factors can decrease the lifespan of steel tube couplers. Exposure to harsh environmental conditions, like extreme temperatures, moisture, and corrosive substances, can speed up the deterioration process. Additionally, if the couplers are subjected to excessive loads or misused, their lifespan may be significantly shortened. To ensure that steel tube couplers last a long time, it is crucial to follow the manufacturer's guidelines regarding their usage, storage, and maintenance. Regular inspections should be carried out to identify any signs of wear, damage, or corrosion. If any issues are detected, immediate repairs or replacements should be done to maintain the safety and integrity of the scaffolding system. In conclusion, while there is no set lifespan for steel tube couplers in scaffolding applications, their durability and longevity can be maximized by properly caring for them, conducting regular maintenance, and adhering to safety guidelines.

- Q:How do steel tube couplers prevent slippage or loosening of scaffolding connections over time?

- Steel tube couplers are specifically designed to prevent slippage or loosening of scaffolding connections over time. These couplers consist of a cylindrical body with internal teeth or gripping mechanisms that securely hold the tubes together. One way they prevent slippage is by providing a tight fit between the tubes. When the coupler is tightened, it creates a strong connection by compressing the tubes together, ensuring there is no room for movement or slippage. This tight fit prevents any loosening of the connection, even under heavy loads or vibrations. Additionally, steel tube couplers often have a locking mechanism that further enhances the stability of the connection. The locking mechanism can be in the form of a bolt or a pin that is inserted through the body of the coupler, effectively locking the tubes in place. This adds an extra layer of security and prevents any potential slippage or loosening over time. Moreover, steel tube couplers are usually made from high-quality, durable steel materials. These materials are known for their strength and resistance to wear and tear. This durability ensures that the couplers can withstand the forces and pressures exerted on the scaffolding connections over time, without compromising their performance. In summary, steel tube couplers prevent slippage or loosening of scaffolding connections over time by providing a tight fit between the tubes, incorporating a locking mechanism, and utilizing durable materials. These features work together to create a stable and secure connection that can withstand the demands of construction and ensure the safety of workers.

- Q:How do steel tube couplers affect the assembly and disassembly process of scaffolding?

- The assembly and disassembly of scaffolding greatly rely on the use of steel tube couplers, which play a vital role in this process. These couplers serve the purpose of connecting and securing the tubes together, guaranteeing a stable and secure structure. To begin with, steel tube couplers simplify the assembly of scaffolding by offering a swift and effective way to connect the tubes. They are specifically designed to perfectly fit onto the tubes, enabling a secure connection without the need for complicated techniques like welding. This results in a quicker and easier assembly process, saving both time and effort. Furthermore, steel tube couplers provide a high level of strength and stability to the scaffolding structure. Made from high-quality steel, these couplers have the capacity to withstand heavy loads, creating a robust framework. This characteristic is of utmost importance in construction projects where the scaffolding must support workers, equipment, and materials at different heights. When it comes to disassembly, steel tube couplers simplify this process by allowing for easy detachment. Unlike other methods of connection such as welding or bolting, couplers can be effortlessly removed without causing any damage to the tubes. This facilitates a faster and more convenient disassembly, especially in situations where the scaffolding needs to be frequently relocated or reconfigured. In addition, steel tube couplers are reusable, enhancing their efficiency in both assembly and disassembly. Once the scaffolding is taken apart, the couplers can be detached and utilized again for future projects. This not only reduces costs but also promotes sustainability by minimizing waste. In conclusion, steel tube couplers have a significant impact on the assembly and disassembly of scaffolding. They simplify the connection process, provide strength and stability, allow for easy detachment, and offer reusability. Their presence ensures a safe and efficient scaffolding structure, making them an indispensable component in construction projects.

- Q:What is the weight of a typical steel tube coupler?

- The weight of a typical steel tube coupler can vary depending on its size and design. However, on average, a steel tube coupler can weigh between 1 to 5 pounds.

- Q:Can steel tube couplers be used for scaffolding projects in areas with limited access?

- In areas with limited access, scaffolding projects can utilize steel tube couplers. These couplers are commonly employed in scaffolding systems due to their ability to establish a sturdy and secure connection between steel tubes, thereby ensuring the stability and safety of the structure. When faced with restricted accessibility, it becomes essential to have a scaffolding system that is both easily transportable and simple to assemble. Steel tube couplers possess the qualities of being lightweight and compact, rendering them particularly suitable for such situations. They can be effortlessly carried and maneuvered into tight spaces, enabling the establishment of scaffolding in areas with limited accessibility. Moreover, steel tube couplers are versatile and can be utilized to create various configurations and designs for scaffolding structures. They can adapt to the specific requirements and needs of the project, enabling the connection of tubes at different angles and facilitating the construction of scaffolding in irregular or challenging environments. All in all, steel tube couplers are a dependable and practical choice for scaffolding projects in areas with limited access. Their attributes of strength, flexibility, and user-friendliness make them the preferred option for ensuring the safety and efficiency of scaffolding operations under such conditions.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Trustable Cuplock Scaffolding System with Best Prices

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 30000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords