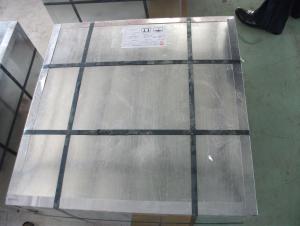

Double Reduced Tinplate

Double Reduced Tinplate Related Searches

Paint For Stainless Steel Peelable Paint For Cars Waterproof PaintHot Searches

Second Hand Scaffolding Poles For Sale Pedestal Fan With Water Spray Price High Mast Light Price List Philips High Mast Lighting Price List Bajaj High Mast Lighting Price List Bike Gps System Price In India Outdoor Led Screen Price Coronation Hot Water Bottle Price Price Of Water Cooler Solar Module Wholesale Price Evacuated Tube Solar Collectors Price Abb 50 Kw Solar Inverter Price Wholesale UPVC Pipe Price Philippines Mtn Lumos Solar Inverter Price Lorentz Solar Pumps Price Alcoa Aluminum Stock Price Today Aluminum Skirting Price Price Of Century Plywood 19Mm pvc resin price index Lasani Wood Sheet PriceDouble Reduced Tinplate Supplier & Manufacturer from China

Okorder.com is a professional Double Reduced Tinplate supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Double Reduced Tinplate firm in China.Hot Products

FAQ

- The welding methods commonly used for tinplate include spot welding, seam welding, and resistance welding.

- Some common challenges faced in the production of tinplate include ensuring consistent coating thickness, preventing defects such as pinholes and wrinkles, maintaining adhesion between the tin coating and base metal, controlling the formation of oxide layers, managing coil and strip handling to avoid damage, and ensuring efficient lubrication during forming processes.

- What kind of material is tinplate?

- Tin plate is tin plated steel, that is iron.

- Yes, tinplate can be used for packaging personal care products. Tinplate is a commonly used material for packaging due to its durability, corrosion resistance, and ability to preserve the quality and shelf life of the products. It is also a sustainable option as it is recyclable and can be reused.

- Tinplate is commonly used in the wine and spirits industry for packaging purposes. It is used to manufacture metal cans, bottles, and closures that help preserve the quality and integrity of the products. Tinplate containers provide a barrier against oxygen, light, and moisture, which helps to prevent oxidation and maintain the taste and aroma of the wine or spirit. Additionally, tinplate packaging is durable, lightweight, and recyclable, making it a popular choice for the industry.

- Using tinplate for electrical components offers several benefits. Firstly, tinplate is highly corrosion-resistant, which helps protect the components from moisture and other environmental factors that can cause damage. Additionally, tinplate has excellent electrical conductivity, ensuring efficient and reliable performance of the electrical components. Moreover, tinplate is lightweight and durable, making it suitable for various applications. Lastly, tinplate is cost-effective, as it is readily available and its production process is relatively inexpensive. Overall, these advantages make tinplate a preferred choice for electrical components.

- Tinplate is not significantly affected by exposure to light. It is a durable material that can withstand various environmental conditions, including light exposure, without any major changes or deterioration.

- Tinplate contributes to the overall sustainability of packaging in several ways. Firstly, tinplate is a highly durable and long-lasting material, which means that packaging made from tinplate can be reused and recycled multiple times without losing its quality. This helps reduce the need for producing new packaging materials, conserving resources and minimizing waste. Additionally, tinplate is 100% recyclable, meaning that it can be easily recovered and turned into new products, reducing the environmental impact associated with its disposal. Moreover, tinplate offers excellent protection and preservation properties, ensuring the longevity and safety of packaged goods, thus reducing food waste and promoting sustainable consumption. Overall, tinplate packaging plays a significant role in achieving a circular economy by minimizing waste generation, conserving resources, and promoting sustainable practices.