Geogrid For Pavers

Geogrid For Pavers Related Searches

Best Paint For Stainless Steel Blanket Insulation For Steel Buildings Primer For Galvanized Steel Foam Filter For Stainless Steel H S Code For Stainless Steel Surface Grinding Wheels For Stainless Steel Surface Grinding Wheels For Hardened Steel Hole Saw For Stainless Steel Paint For Stainless Steel Stainless Steel For BbqHot Searches

Steel Mesh Panels For Sale Price For Stainless Steel Scrap Scrap Price For Stainless Steel Price For Stainless Steel Stainless Steel Plate For Sale Stainless Steel Tank For Sale Stainless Steel Sheets For Sale Cheap High Tea Sets For Sale Stainless Steel Tanks For Sale Stainless Steel For Sale High Density Fiberboard For Sale Solar Hot Water Collectors For Sale Scaffolding For Sale In Uae Scaffolding For Sale In Ireland Scaffolding For Sale In Houston Type Of Inverter For Solar Price Of Shipping Containers For Sale Types Of Inverter For Solar Stock Price For Aluminum Steel Mesh Panels For SaleGeogrid For Pavers Supplier & Manufacturer from China

Okorder.com is a professional Geogrid For Pavers supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Geogrid For Pavers firm in China.Hot Products

FAQ

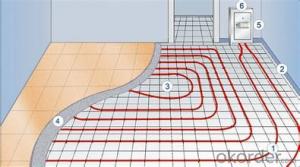

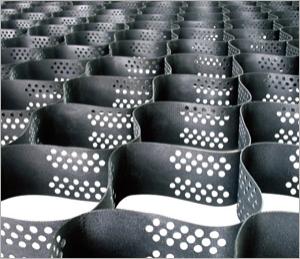

- Geocells are typically manufactured through a process known as extrusion. In this process, a high-density polyethylene (HDPE) sheet is fed through an extruder machine, which heats and melts the material. The molten HDPE is then pushed through a die, giving it the desired hexagonal or rectangular shape of the geocell. The extruded geocells are then cooled and cut to the desired length before being packaged and ready for use in various geotechnical applications.

- Yes, geocells can be used for pipeline bedding. Geocells are often used as a cost-effective and efficient solution for stabilizing and reinforcing soil in various applications, including pipeline bedding. They provide excellent load distribution, soil confinement, and erosion control, which help to ensure the stability and longevity of the pipeline.

- Geocells promote vegetation growth by providing a stable and supportive environment for plants. The cells are filled with soil or other growing media, creating a confined space that holds moisture and nutrients, allowing plant roots to penetrate and establish themselves. The cells also prevent soil erosion, reduce compaction, and enhance water retention, creating favorable conditions for vegetation to thrive.

- Yes, geocells can be used for coastal reclamation projects. Geocells are a type of cellular confinement system that can provide stabilization and erosion control in coastal areas. They can be filled with granular materials to create a stable foundation for reclamation projects, preventing erosion and promoting land growth. Geocells also allow for the natural flow of water and can be environmentally friendly solutions for coastal reclamation.

- Some of the key design considerations for geocells include the choice of material, cell size and shape, cell height, connection strength, and overall stability. The material used for geocells should possess sufficient strength, durability, and resistance to environmental factors. The size and shape of the cells are determined based on the specific application and desired load-bearing capacity. The height of the cells influences the confinement and support provided to the infill material. Strong connections between cells are crucial to maintain the overall integrity of the geocell structure. Lastly, ensuring stability against forces like shear and vertical loading is essential for a successful geocell design.

- Yes, geocells can be used for trail construction. Geocells are a type of geosynthetic material that provide soil stabilization and erosion control. They can be filled with soil or aggregate and placed on the trail surface to create a stable and durable pathway. Geocells are often used in trail construction projects to prevent erosion, maintain trail integrity, and improve accessibility for hikers, bikers, and other users.

- Geocells improve the load distribution of bridge decks by providing a stable and reinforced base. These three-dimensional honeycomb-like structures are filled with compacted soil or aggregate, creating a strong and rigid foundation. The geocells effectively distribute the load across a larger area, reducing stress concentrations and preventing differential settlement. This enhanced load distribution helps to increase the lifespan of the bridge deck and enhance its structural integrity.