Geogrid Tx150

Geogrid Tx150 Related Searches

Fridge With Freezer On Bottom Driveway Pillars With Lights Blu Ray Player With Recorder Blu Ray Player With Internet Geogrid In Retaining Walls 1708 Biaxial Fiberglass Tape Pullout Resistance Of Geogrid Geogrid Warp Knitting Machine Srw 3 Series Geogrid Biaxial Plastic GeogridHot Searches

Fiberglass Scaffolding For Sale Fiberglass Panels For Sale Fiberglass Greenhouses For Sale Geogrid Fabric For Sale Gas Powered Core Aerator For Sale Revolution 4 Propeller For Sale Alabaster Carving Stone For Sale Geogrid For Sale Near Me Tensar Geogrid For Sale Geogrid For Sale Ex Display Log Cabins For Sale Photoelectric Cells For Sale Athletic Lockers For Sale Cubicle Partitions For Sale Stearman Propeller For Sale Palram Greenhouses For Sale Gumbo Bowls For Sale Suzuki Propellers For Sale Freight Crates For Sale Outhouse Sheds For SaleGeogrid Tx150 Supplier & Manufacturer from China

Okorder.com is a professional Geogrid Tx150 supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Geogrid Tx150 firm in China.Hot Products

FAQ

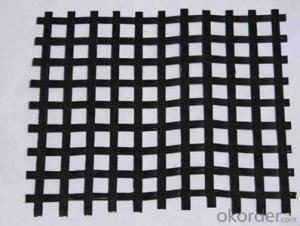

- The standards for geogrid testing and certification are outlined by various organizations such as ASTM International (American Society for Testing and Materials) and ISO (International Organization for Standardization). These standards cover a range of parameters including tensile strength, elongation, aperture size, junction strength, and durability. Testing methods and acceptance criteria are defined to ensure that geogrids meet the necessary performance requirements for their intended applications. Certification is typically granted by accredited third-party laboratories or certification bodies after successful compliance with these standards.

- The effect of soil type on geogrid performance can vary significantly. Different soil types have varying properties such as cohesion, friction angle, permeability, and compaction characteristics, which can directly influence the interaction between the geogrid and the soil. The geogrid's effectiveness in reinforcing the soil, providing stability, and distributing loads can be affected by factors like soil type, particle size distribution, moisture content, and density. Ultimately, the geogrid's performance may be enhanced or compromised depending on the specific soil type it is installed in.

- The factors that affect the creep behavior of geogrids include the type and quality of the material used in the geogrid, the magnitude and duration of the applied load, the environmental conditions such as temperature and moisture, and the installation and construction techniques employed.

- Specifications and parameters of Geotextiles

- Product specification is between SNG100-SNG1500. Width is 1-8m, long 50-100m (or according to customer requirements to produce)

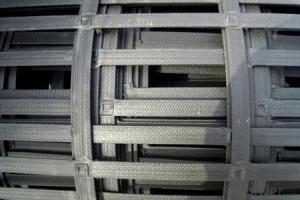

- What is the principle of geogrid?

- GSZ: 1 what are the characteristics of high strength steel wire, steel plastic composite geogrid tension by warp knitting bear, resulting in high tensile modulus at low strain capacity, vertical and horizontal rib synergistic effect, give full play to the role of Geogrid on soil type. 2, steel plastic composite geogrid vertical steel rib weft woven into nets, an outer coating layer forming a steel wire and the outer coating layer can destroy the function of coordination, elongation is very low (less than 3%). The main force unit of steel plastic composite geogrid is steel wire, and the creep is very low. 3, through the production process of plastic surface treatment, suppress the rough pattern, in order to enhance the surface roughness of the grid, improve the steel plastic composite geogrid and soil friction coefficient. 4, steel plastic composite geogrid width of up to 6m, to achieve high efficiency, economic effect of reinforcement. 5, steel plastic composite geogrid used high-density polyethylene can ensure that: at room temperature will not be affected by acid and alkali and salt solution, or oil erosion; will not be dissolved by water or microbial damage. At the same time, the high molecular weight of polyethylene is also sufficient to resist ultraviolet radiation caused by aging. The grille stress aspect rib synergistic effect, can not generate node crack or damage. But in the actual project, after the packing compaction, therefore has not been subjected to the ultraviolet light and the oxygen erosion, therefore completely may satisfy the permanent construction request.

- Yes, geogrids can be installed on steep slopes. Geogrids are commonly used in the construction industry to reinforce soil and provide stability on slopes. They are designed to withstand high tensile forces and can effectively reinforce the soil, preventing erosion and slope failure even on steep slopes.

- Yes, geogrids can be used in mining haul roads. Geogrids are commonly used in the construction of haul roads in mining operations to improve road stability, increase load-bearing capacity, and reduce maintenance costs. They provide reinforcement and stabilization to the road base, preventing deformation and rutting caused by heavy mining vehicles.

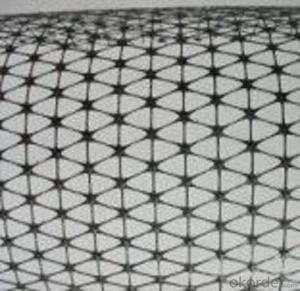

- Basic introduction of fiberglass geogrid

- With resistance and aging properties of alkali resistant properties, widely used in asphalt pavement, cement concrete pavement and roadbed reinforcement; both rigid pavement and flexible pavement can be applied, compared with the traditional pavement, can reduce the cost, prolong life, prevent road reflective crack. Fiberglass geogrid can also be used in railway, airport, water conservancy, dams and other soft soil reinforcement and road base reinforcement.