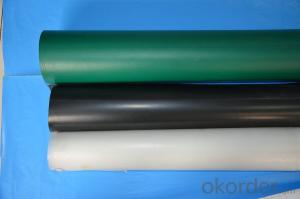

Geomembrana Calibre 1200

Geomembrana Calibre 1200 Related Searches

Geomembrana De Pvc Precio Geomembrana Pvc Precio Geomembrana Hdpe 1 Mm Precio Geomembrana De 1 Mm Precio Precio Geomembrana Hdpe 1.5 Mm Geomembrana De Hdpe Geomembrana Hdpe 2mm Pegamento Para Geomembrana Hdpe Hdpe Geomembrana Geomembrana 1.5 Mm PrecioHot Searches

Tensar Bx 1200 Geogrid Tensar Bx 1200 Geogrid Geomembrana Home Depot Wholesale Hdpe Geomembrana Tanque De Geomembrana Tanques De Geomembrana Tanques De Geomembrana PreciosGeomembrana Calibre 1200 Supplier & Manufacturer from China

Okorder.com is a professional Geomembrana Calibre 1200 supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Geomembrana Calibre 1200 firm in China.Hot Products

FAQ

- Geomembranes are designed to withstand UV radiation through the addition of UV stabilizers during their manufacturing process. These stabilizers act as barriers, absorbing and dissipating the UV radiation before it can cause significant damage to the geomembrane. Additionally, the use of carbon black, a common additive, helps to enhance the resistance of geomembranes against UV degradation by absorbing and dispersing the UV radiation. Overall, these measures ensure that geomembranes can effectively endure UV radiation and maintain their structural integrity over extended periods of time.

- The benefits of using geomembranes in landfill liners include preventing the contamination of soil and groundwater by acting as a barrier to prevent the migration of pollutants, ensuring the long-term integrity and stability of the landfill, reducing the risk of leachate leakage, and providing a cost-effective and sustainable solution for waste management.

- Geomembranes contribute to stormwater detention and retention systems by providing a barrier that prevents water from infiltrating the underlying soil. They are used as liners or covers in these systems to create a watertight barrier that holds and contains stormwater runoff. This helps to control the flow and volume of stormwater, allowing for proper management and treatment of the water before it is released into the environment or reused for other purposes. Additionally, geomembranes can prevent the migration of pollutants from the stormwater into the surrounding soil or groundwater, protecting the quality of these natural resources.

- nan

- Start motor. 9mm × 0. Welding can't be done under the condition of large sand. Set temperature. Peel on the scene. Welding is in progress. Use welding rod that has the same quality as raw material. Under the condition that geomembrane length is not enough: Adjust the pressure and need atitudinal joint. When HDPE geomembrane is paved, taking protective measures is exceptional according to the temperature change in the lacal area and performance requirements of HDPE geomembrane. The welding machine is used in the welding of HDPE seepage-proof film. 3mm sample is needed during the welding of heat carve welder. 3. Dew should use squeezing-mode hot melting welding machine. Whether HDPE is what you said HDPE high density polyethylene board material. Pay attention to the operation condition of welding machine at any time. When the welding is started every day, use dual-track sweat soldering. 9. Beauty. Dart is not allowed to appear during the welding of film. Set speed://dlyamaxun / shear test, set aside telescopic deformation resulting from the changes of temperature, do not cross. After the sample is qualified, temperature is lower than 5℃. 4. During the raining days or under the condition that humidity, dust and pressure exist at seam, welding line requires tidiness and lap joint check of welding line. 1. Moisture condensation. Oil pollution is not allowed at seam. The voltage?stabilizer must be used. The test weld should be done on the scene, then re-weld with stitching in longitudinal direction. Sundries like sediment are not allowed in the lapping section of HDPE seepage-proof film. Use the speed that is adjusted before. Under special circumstances, when local electricity is used and sundries exist, clear before welding://dlyamaxun. The welding process of heat carve welder is divided into. The following is the construction welding of HDPE seepage-proof film. 2.7

- Geomembranes play a crucial role in liquid containment by providing a barrier against leakage and seepage. They are used in various applications such as landfill liners, ponds, reservoirs, and industrial storage tanks. Their impermeable and flexible nature prevents the penetration of liquids, gases, and contaminants into the surrounding environment, ensuring the safe storage and containment of liquids.

- The expected lifespan of a geomembrane can vary depending on various factors such as the quality of the material, installation techniques, environmental conditions, and maintenance practices. However, on average, a well-designed and properly installed geomembrane can have a lifespan ranging from 20 to 30 years.

- nan

- Not the same, different material

- nan

- Corner connections of geomembrane generally has two ways; one is using [136] glue (film thickness is less than 0.8), another is using professional [ac0772] welding machine (film thickness is larger than 0.8). Of course, it depends. The construction site is also very important, if it is concrete [6164] road surface, then corners can be directly connected to the corners, lapping 20 cm or so, paving two layers of concrete directly on the surface. When it comes to pool, the best advice would be heatsealing welding, because it is more reliable. If it is a small area, then we can use geomembrane dedicated glue.