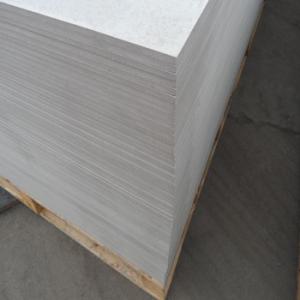

Insulated Floor Boards

Insulated Floor Boards Related Searches

Best Stainless Steel For Knives Primer For Galvanized Steel H S Code For Stainless Steel Wd 40 For Stainless Steel Spray Paint For Stainless Steel Glue For Stainless Steel Stainless Steel For Bbq Step Bit For Stainless Steel Sponge For Stainless Steel Coatings For Stainless SteelHot Searches

Steel Mesh Panels For Sale Cheap High Tea Sets For Sale High Density Fiberboard For Sale Solar Hot Water Collectors For Sale Scaffolding For Sale In Uae Scaffolding For Sale In Ireland Scaffolding For Sale In Houston Type Of Inverter For Solar Used Solar Inverter For Sale Portable Led Signs For Sale Stone Hot Water Bottles For Sale Large Led Screens For Sale 1/4 Aluminum Plate For Sale H4 Led Headlight Bulbs For Sale Flexible Solar Cells For Sale Air Pump For Aquarium Price Solar Edge Inverter For Sale 5kw Solar Inverter For Sale Printed Solar Cells For Sale Aluminum Round Stock For SaleInsulated Floor Boards Supplier & Manufacturer from China

Okorder.com is a professional Insulated Floor Boards supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Insulated Floor Boards firm in China.Hot Products

FAQ

- What is the best thing to do with the top floor of the house?

- When dealing with nodes that have been repeatedly leaked for years, you need to be deeper and wider. Fill more dense to be more times, you can ensure that after treatment no longer cracked again. Extra large gushing water plugging. You can apply for plugging partner at the same time, you can adjust to 2-5 seconds quick condensate plugging.

- Can someone tell me if they know or what they would think is stronger, six cement blocks stacked high or a board that is 6 feet long and 6 by 6?

- are the cement blocks stacked without mortar? are the cement blocks loaded in bending or compression? is the board loaded in bending or compression? What is the criterion of failure? cracking or breaking? Not a fair comparison with out some explanation.

- Oulang cement fiberboard and Taiwan Rong calcium carbonate plate difference

- Cement board is cement as the main condensing material through the formation of natural conservation, high strength, but the deformation coefficient.

- What is the difference between cement calcium silicate board and cement fiberboard

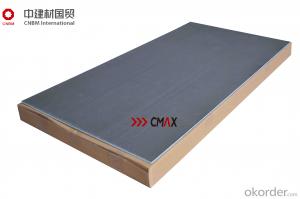

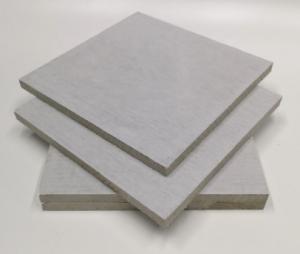

- Cement fiberboard, also known as fiber cement board. Is based on siliceous, calcium material as the main raw material, adding plant fiber, through the pulp, copy, pressure, curing from a new type of building materials. After the high-pressure production of cement fiber board, also known as fiber cement pressure plate, its performance is better than the non-pressurized cement fiber board. Fiber cement board length and width of the standard specifications are 1200 * 2400mm and 1220 * 2440mm, manufacturers can basically customize the length of 2000-2500mm, width of 1000-1250mm within any specifications, other specifications can be cut on this basis. Fiber cement cement board thickness of 2.5,3,3.5,4,5,6,8,9,10,12,15,18,20,24,25,30,40,60,90 mm, the strength of the manufacturers Can be customized within any thickness of 2.5-100mm. Thickness of 4mm or less known as ultra-thin plate, 4-12mm become a conventional plate, 15-30mm and above known as thick plate, 30mm or more known as the thick plate. No small press manufacturers can only produce 6-12mm ordinary cement board; general manufacturers can only produce 4-12mm conventional board, thick plate to do well, thick plate can not do; thickness 2.5-100mm can do the manufacturers The country is small. Cement fiber board is widely used, the sheet can be used for ceiling materials, perforation can be used as sound-absorbing ceiling. Conventional board can be used for wall and / or decorative materials, thick plate can be used as LOFT steel floor board, attic board, external wall insulation board, wall panels and so on.

- cost of installation per sq foot

- I used to charge 2.50$ a s/f for installing cement board. This would include the board, thin set to set it ( floors) and nails/ screws. Any questions you can e mail me through my avatar ..GL

- 60 thick foam cement board Ⅱ how much noise

- Product density is light, the volume of dry, the density of about 250kg / cubic, the board through the National Testing Center 1.5 million times the anti-fatigue vibration test, the board and the steel structure as a whole, can reach 9 earthquake.

- Installing tile in my laundry room. put down the cement board with a mortar/thin set base under it, then nailed it down according to manufacturer's instructions. The mortar/thin set totally dried then I had to do a few loads of laundry before I was able to put any tile down. Unfortunately one of the hoses hooked up to the washer leaked and soaked the cement board and I'm sure also the sub-floor. Do I need to rip out the cement board and re install before I install the tile? obviously I would need to ensure the floor is fully dry before I install the tile. Thanks

- I do not think you need to rip it out. Just let it dry for a week or so before you install the tile.

- I have Joint Compound and cement board tape, How do i fix a 6 inch hole in drywall? Anything else I Need?

- Spackle should solve your problem. If the hole is deep, put the spackle on in two stages, allowing the first batch to completely dry. this first batch should mostly fill the hole. As it dries you will see it sink in a bit. That's why you need to do a second batch, this time, applied with a spackling knife. Feather the edges and you shouldn't need to do much sanding to finish off the job. When almost completely dry, I use a damp cloth to smooth the edges.