Interior Car Light Bulbs

Interior Car Light Bulbs Related Searches

Micro Inverter For Solar Panel Plastic Wall Coverings For Bathrooms Geogrid For Retaining Wall Solar Panel With Ac Inverter Solar Panel With Inverter Kit Solar Panel Kits With Inverter Retaining Wall With Geogrid Galvanized Steel Panel Thin Wall Stainless Steel Tube Stainless Steel Peg BoardHot Searches

Steel Mesh Panels For Sale Cheap High Tea Sets For Sale High Density Fiberboard For Sale Solar Hot Water Collectors For Sale Scaffolding For Sale In Uae Scaffolding For Sale In Ireland Scaffolding For Sale In Houston Type Of Inverter For Solar Used Solar Inverter For Sale Portable Led Signs For Sale Stone Hot Water Bottles For Sale Large Led Screens For Sale 1/4 Aluminum Plate For Sale H4 Led Headlight Bulbs For Sale Flexible Solar Cells For Sale Air Pump For Aquarium Price Solar Edge Inverter For Sale Aluminum Bar Stock For Sale 5kw Solar Inverter For Sale Printed Solar Cells For SaleInterior Car Light Bulbs Supplier & Manufacturer from China

Okorder.com is a professional Interior Car Light Bulbs supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Interior Car Light Bulbs firm in China.Hot Products

FAQ

- How did the trademark on the LED bulb go up?

- Laser printing and screen printing, pad printing can be, look at the needs and equipment.

- Ordinary lamp LED bulb can?

- As long as the inside of the interface is the same, for example, the E27 interface (ordinary spiral, that can be installed energy-saving lamps) installed there is no problem, LED bulb is now a lot of 110V-220V high voltage power supply, so the stability is very strong, the key is to save electricity, saving seventy percent than the energy-saving lamp, no effect, ease of use.

- What are the types of LED bulb?

- power LED bulb is the traditional incandescent lamp 1/10, half of the power of the energy-saving lamp, high efficiency and energy saving is the best

- The difference between an incandescent lamp, an energy-saving lamp, and an energy-saving LED bulb

- 3, the monomer minimum power is different. Incandescent power is a common monomer, 15W, energy-saving lamps common power 8W, and then low lighting effect is not good, and LED lamp monomer minimum power is very low, can be less than 1W.The luminescence principle of

- LED can the bulb be used in the bathroom?

- From a long-term perspective is not enough, you can choose a lamp are closed, such as ceiling lamps what, now have special indoor lamps, but you must not use ordinary lamps, because LED lights to the heat at the edge of the open slot or empty, easy water.

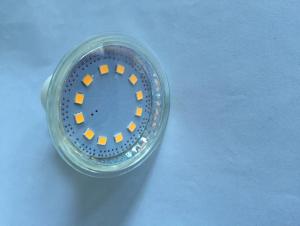

- What does the LED bulb patch mean?

- According to different applications, different size, cooling scheme and luminous effect of.LED packaging forms. At present, according to the classification of LED package are mainly Lamp-LED, TOP-LED, Side-LED, SMD-LED, High-Power-LED, Flip Chip-LED Lamp-LED (vertical LED) emerged in the early Lamp-LED is in line LED, it adopts the form of sealing packaging. The potting process is the first injection of liquid epoxy resin in LED molding cavity, and then insert the pressure LED bracket welding, in the oven make epoxy resin after curing, the LED from the cavity from the molding. Due to the relatively simple fabrication process, low cost, have a higher market share. (SMD-LED surface mount LED) patch LED is pasted on the surface of a wiring board, suitable for SMT processing, can be reflow, a good solution to the brightness, perspective, smoothness, consistency, reliability and other issues, the The lighter PCB plate and a reflecting layer material, improved to remove the carbon steel pin dip LED heavier, the display of epoxy resin less reflective layer needs to fill, to reduce the size, reduce the weight. In this way, the surface mount LED can easily reduce the weight of the final product in half, make the application more perfect.

- LED what is the plastic shell of the bulb? What plastic material is better? What do you need to pay attention to?

- PDT flame retardant plastic, good heat dissipation, flame retardant effect, you see is not very good?

- Want to buy a few LED bulb, do not know how to identify the quality of good or bad, ask for solution ~!

- Power supply must be constant current power supply. This must, do not have that resistance. The constant current source resolution methods, there is no power is apart of a 8 foot IC, if not, no junk to, also not all the IC are good stuff, a famous lighting city have specialized quality of constant current power supply.