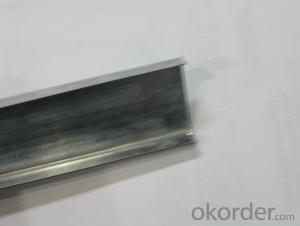

Stock Aluminum Profiles

Stock Aluminum Profiles Related Searches

Best Paint For Stainless Steel Paint For Galvanized Steel Steel Frames For Furniture Self Tapping Screws For Steel Surface Grinding Wheels For Hardened Steel Hole Saw For Stainless Steel Paint For Stainless Steel Stainless Steel For Bbq Step Bit For Stainless Steel Sponge For Stainless SteelHot Searches

Galvanized Steel Scrap Price Galvanized Steel Prices Stone Wall Tiles Cost Steel Mesh Panels For Sale Price For Stainless Steel Scrap Scrap Price For Stainless Steel Cheap High Tea Sets For Sale Stainless Steel Tanks For Sale High Density Fiberboard For Sale Solar Hot Water Collectors For Sale Scaffolding For Sale In Uae Scaffolding For Sale In Ireland Scaffolding For Sale In Houston Type Of Inverter For Solar Price Of Shipping Containers For Sale Types Of Inverter For Solar Stock Price For Aluminum Used Solar Inverter For Sale Portable Led Signs For Sale Stone Hot Water Bottles For SaleStock Aluminum Profiles Supplier & Manufacturer from China

Okorder.com is a professional Stock Aluminum Profiles supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Stock Aluminum Profiles firm in China.Hot Products

FAQ

- How can the aluminum tube bending be processed and how to make manual bending equipment?

- How can aluminum tube bending be processed?Aluminum pipe to see what material, if 6063 or 6061, such as aluminum alloy, do not want to bend, and must be in the factory before the aging treatment bending, not without.

- Yes, aluminum pipes can be suitable for desalination plants. Aluminum is a lightweight, corrosion-resistant material that can withstand the harsh conditions of desalination plants, which involve high-pressure and corrosive seawater. Aluminum pipes have excellent resistance to saltwater corrosion, making them a reliable choice for conveying saltwater throughout the desalination process. Additionally, aluminum pipes are easy to install, require minimal maintenance, and have a long lifespan, making them a cost-effective option for desalination plants.

- The specific application and industry standards play a significant role in the variation of wall thickness in aluminum pipes. Generally, aluminum pipes have a wall thickness that falls between 1/16 inch and 1/4 inch. The exact thickness relies on factors like pipe diameter, intended use, and the necessary strength and durability. To ensure the correct wall thickness for a specific project or application, it is crucial to refer to industry standards and specifications or seek advice from a professional engineer or supplier.

- Ask for advice,According to the type of aluminum alloy, Al-Si, Al-Mg, Al-Mg-Si, Al-Mn, Al-Cu, Al-Zn-Mg (T0-T8 heat treatment); if the steel type crystal like austenite, ferrite, Aluminum Alloy have similar crystal like heat treatment, whether similar to the regulation, for advice! Thank you

- There is no phase change in the process of heating aluminum alloy, so there is no corresponding hard treatment by heat treatment. However, some aluminum parts which are extruded by cold can be softened by heat, but the softening process is more to eliminate the stress without phase change. For these Aluminum Alloy you said, in fact, we often say that the 4XXX series, 6XXX series, 5XXX series aluminum forging, antirust aluminum, 3XXX series, 2XXX series aluminum, aluminum 7XXX series, 7XXX series I've seen can be tempered (just to stress), other if there is no need to do heat treatment, but the aluminum can generally do hard oxidation hardening, but surface hardening, the hardness is not the core.

- Yes, aluminum pipes can be used for wastewater pumping stations. Aluminum pipes are lightweight, corrosion-resistant, and durable, making them suitable for various applications, including wastewater pumping stations. They have excellent resistance to rust and are less likely to corrode compared to other metals, such as iron or steel. Additionally, aluminum pipes have a smooth interior surface, which helps to minimize friction and improve the flow of wastewater. However, it is essential to consider the specific requirements of the wastewater pumping station, including the pressure, flow rate, and chemical composition of the wastewater, to ensure that aluminum pipes are the appropriate choice for the project.

- Air conditioning copper aluminum tube life is generally a few years?

- The life of the air conditioner is 8-10 years, and no one has ever mentioned the life of the copper tube. Try not to use the aluminum tube.

- What happened to the mold sticking when drawing the aluminum pipe? How do you make the mold?

- Such as tensile material, material circle diameter, tensile concave convex mold with the size, size, material sticking position, whether or not to pull the thin stretch, lubricating oil type and so on, which is the hard alloy you say ah, we generally use outside processing, not only tungsten steel, pull thin shallow drawing himself with the lathe. Their hard alloy quenching, the workpiece material is easy to stick, 0.05MM does not produce sticky material, the size of R according to the general drawing coefficient depends on the material, if the material is allowed, R can be a little friction, the area is small, the workpiece pulled out a little too smooth, the temperature is not too high to die I also met sticky material problems, 0.5MM aluminum plate, 7 points pulled into a pen inside the ink tube, which is always a sticky material, later changed the way the size of the die,

- Special considerations must be taken into account for expansion joints when using aluminum pipes. Aluminum has a higher coefficient of thermal expansion compared to other materials, causing it to expand and contract more when exposed to temperature changes. This expansion and contraction can lead to stress, strain, and potential damage to the piping system if not properly addressed. To address this issue, it is crucial to install expansion joints at appropriate intervals along the aluminum pipe system. These expansion joints allow the pipe to expand and contract freely without exerting excessive stress on the system. Factors such as the temperature range the pipes will be exposed to and the length of the pipe runs should be considered when determining the spacing and design of the expansion joints. Considering the type of expansion joint to use for aluminum pipes is also important. It is recommended to use expansion joints made from materials compatible with aluminum, such as stainless steel or elastomeric materials, to ensure compatibility and longevity. Furthermore, the design and installation of these expansion joints should adhere to manufacturer guidelines and industry standards to ensure proper functionality. Regular inspections and maintenance of the expansion joints are essential to detect any signs of wear, damage, or failure. Proper care and maintenance of the aluminum pipe system, including the expansion joints, will help prevent leaks, pipe damage, and costly repairs in the long term. In conclusion, special considerations are necessary for expansion joints when working with aluminum pipes due to their higher coefficient of thermal expansion. The proper installation, spacing, and design of expansion joints, along with regular maintenance, are crucial for ensuring the durability and functionality of the aluminum pipe system.