All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What is the impact of alloy composition on the cost and performance of aluminum coils?

The impact of alloy composition on the cost and performance of aluminum coils is significant. The choice of alloy composition directly influences the mechanical properties, such as strength, durability, and corrosion resistance, of the aluminum coils. Higher alloying elements like copper, manganese, and zinc can enhance these properties but also increase the cost of production. On the other hand, lower alloying elements like magnesium and silicon can reduce costs but may compromise certain performance characteristics. Therefore, finding the right balance between alloy composition, cost, and desired performance is crucial in determining the overall quality and price of aluminum coils.

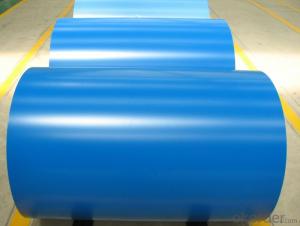

How do you ensure the uniformity of coating thickness on aluminum coils?

The uniformity of coating thickness on aluminum coils can be ensured through various methods such as utilizing advanced coating technology, implementing precise application techniques, and employing quality control measures. These may include using automated coating systems that can accurately control the thickness and distribution of the coating material, ensuring a consistent application across the entire surface of the coil. Additionally, regular monitoring and calibration of coating equipment, along with conducting thorough inspections and tests during the coating process, can help identify and address any deviations or inconsistencies in the coating thickness to maintain uniformity.

What is the role of aluminum coils in the automotive suspension systems?

The role of aluminum coils in automotive suspension systems is to provide support and help absorb shocks and vibrations from the road. These coils, also known as coil springs, are designed to compress and expand as the vehicle moves, allowing for a smoother and more comfortable ride. Aluminum coils are preferred in suspension systems due to their lightweight and high strength properties, which help improve overall vehicle performance and fuel efficiency.

Are there any fire safety considerations when using aluminum coils in construction?

Yes, there are fire safety considerations when using aluminum coils in construction. Aluminum has a high melting point and is generally considered to be fire-resistant. However, in the event of a fire, aluminum can conduct heat and may contribute to the spread of fire. It is important to ensure that proper fire-resistant insulation and fire barriers are in place when using aluminum coils to minimize fire risks in construction. Additionally, regular inspections and maintenance should be carried out to identify and address any potential fire hazards associated with the use of aluminum coils.

Wholesale Aluminum Coils from supplier in Benin

Thank you for considering us as your supplier of Aluminum Coils in Benin. Our company, a subsidiary of CNBM, is dedicated to providing a comprehensive range of products and services to meet your needs.

With our years of experience in the Benin market, we have gained valuable insights into the unique requirements and challenges of projects in the region. This enables us to offer tailored solutions and assist you with product selection, technical support, and project management.

By choosing us as your trusted supplier, you can benefit from our expertise, extensive product range, and reliable services. We are committed to delivering high-quality products and exceptional customer service to ensure your satisfaction.

Please feel free to contact us today for all your Aluminum Coils requirements in Benin. We look forward to serving you.

With our years of experience in the Benin market, we have gained valuable insights into the unique requirements and challenges of projects in the region. This enables us to offer tailored solutions and assist you with product selection, technical support, and project management.

By choosing us as your trusted supplier, you can benefit from our expertise, extensive product range, and reliable services. We are committed to delivering high-quality products and exceptional customer service to ensure your satisfaction.

Please feel free to contact us today for all your Aluminum Coils requirements in Benin. We look forward to serving you.