All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

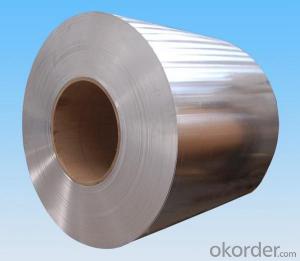

What are the methods for inspecting the surface quality of aluminum coils?

There are several methods for inspecting the surface quality of aluminum coils. These include visual inspection, which involves manually examining the surface for any defects or imperfections. Another method is using a magnifying glass or microscope to closely examine the surface for fine details. Additionally, non-destructive testing techniques such as ultrasonic testing can be used to detect any hidden flaws or defects within the aluminum coils.

How do you determine the appropriate thickness of aluminum coils for specific applications?

To determine the appropriate thickness of aluminum coils for specific applications, several factors need to be considered. These include the desired strength and durability of the coils, the weight-bearing capacity they must handle, the expected environmental conditions, and any specific industry standards or regulations. Additionally, the required dimensions and shape of the coils, as well as the fabrication and manufacturing processes involved, play a crucial role in determining the appropriate thickness. Comprehensive analysis and consultation with experts, such as engineers or metallurgists, are essential in making an informed decision regarding the suitable thickness of aluminum coils for specific applications.

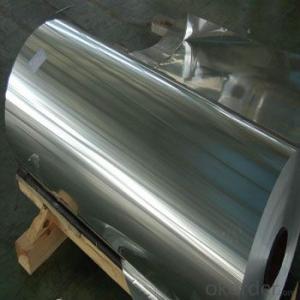

What is the role of aluminum coils in the food and beverage industry?

Aluminum coils play a crucial role in the food and beverage industry as they are commonly used for packaging and preserving various products. The coils are utilized to create aluminum cans, trays, and lids, which are lightweight, durable, and offer excellent protection against moisture, light, and oxygen. These properties make aluminum coils ideal for ensuring the quality and extending the shelf life of food and beverage products. Additionally, aluminum is a sustainable material that can be easily recycled, further enhancing its significance in promoting environmentally friendly packaging solutions.

Are there any regulations regarding the recycling of aluminum coils?

Yes, there are regulations regarding the recycling of aluminum coils. These regulations vary depending on the country or region, but they generally aim to promote the proper handling, collection, and recycling of aluminum coils to minimize environmental impact and maximize resource efficiency. It is important to comply with these regulations to ensure responsible and sustainable recycling practices.

Wholesale Aluminum Coils from supplier in Brazil

Our team of experts is ready to assist you with any inquiries or requests you may have. Whether you need assistance with product selection, technical support, or pricing information, we are here to help.

We understand the importance of timely and efficient delivery, which is why we strive to provide fast and reliable shipping services. With our strong logistics network, we can ensure that your Aluminum Coils are delivered to you in a timely manner, no matter where you are located in Brazil.

Furthermore, we are committed to maintaining the highest standards of quality in all our products. Our Aluminum Coils are manufactured using advanced technology and strict quality control measures, ensuring that you receive only the best products.

At our company, we value the relationships we build with our customers. We aim to establish long-term partnerships based on trust, reliability, and mutual success. Our team is dedicated to providing exceptional customer service and support throughout your entire procurement process.

In conclusion, as a leading supplier of Aluminum Coils in Brazil, we offer a comprehensive range of products, efficient procurement services, and valuable market expertise. We are committed to meeting your specific requirements and delivering high-quality products to ensure the success of your projects. Choose us as your trusted Aluminum Coils supplier and experience the difference.

We understand the importance of timely and efficient delivery, which is why we strive to provide fast and reliable shipping services. With our strong logistics network, we can ensure that your Aluminum Coils are delivered to you in a timely manner, no matter where you are located in Brazil.

Furthermore, we are committed to maintaining the highest standards of quality in all our products. Our Aluminum Coils are manufactured using advanced technology and strict quality control measures, ensuring that you receive only the best products.

At our company, we value the relationships we build with our customers. We aim to establish long-term partnerships based on trust, reliability, and mutual success. Our team is dedicated to providing exceptional customer service and support throughout your entire procurement process.

In conclusion, as a leading supplier of Aluminum Coils in Brazil, we offer a comprehensive range of products, efficient procurement services, and valuable market expertise. We are committed to meeting your specific requirements and delivering high-quality products to ensure the success of your projects. Choose us as your trusted Aluminum Coils supplier and experience the difference.