All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What are the recycling and sustainability initiatives related to steel sheet production?

The recycling and sustainability initiatives related to steel sheet production focus on reducing environmental impacts throughout the entire lifecycle of steel sheets. These initiatives include promoting the use of recycled steel scrap as a raw material, implementing energy-efficient production processes, reducing water consumption, and minimizing waste generation. Additionally, efforts are made to enhance the recyclability of steel sheets, ensuring that they can be easily and efficiently recycled at the end of their useful life. These sustainability initiatives aim to conserve resources, reduce greenhouse gas emissions, and foster a circular economy in the steel sheet industry.

What is the role of steel sheets in earthquake-resistant building construction?

Steel sheets play a crucial role in earthquake-resistant building construction by providing strength, flexibility, and stability to the structure. They are used as reinforcement material in concrete and masonry, enhancing the building's ability to withstand seismic forces. Steel sheets distribute and dissipate the energy generated during an earthquake, minimizing damage and preventing collapse. Additionally, their ductility allows them to bend and deform without breaking, further improving the building's resilience against seismic vibrations.

What are the safety measures when handling and cutting steel sheets?

When handling and cutting steel sheets, there are several important safety measures to follow. Firstly, it is crucial to wear appropriate personal protective equipment (PPE) such as safety goggles, gloves, and steel-toed boots to protect against potential injuries. Additionally, using a well-maintained and properly adjusted cutting tool, preferably a power shear or a plasma cutter, ensures safer and more precise cuts. It is important to secure the steel sheet firmly in place to prevent movement during cutting, reducing the risk of accidents. Regularly inspecting and maintaining the cutting equipment, as well as ensuring a clean and organized work area, helps to prevent potential hazards. Lastly, proper training and knowledge of safe cutting techniques, including the correct positioning of hands and body, are essential to minimize the risk of injury.

Wholesale Steel Sheets from supplier in Djibouti

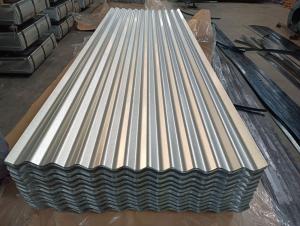

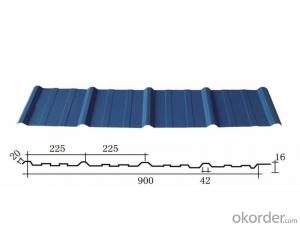

Our Steel Sheets are manufactured using the highest quality materials and undergo rigorous testing to ensure durability and reliability. We offer a wide range of Steel Sheets, including hot-rolled, cold-rolled, galvanized, and stainless steel sheets, to cater to various applications and industries.

When you choose us as your supplier, you can expect competitive prices, prompt delivery, and exceptional customer service. We understand the importance of meeting deadlines and strive to fulfill orders in a timely manner, ensuring that your projects stay on track.

Our team of experienced professionals is dedicated to providing technical support and assistance throughout the entire procurement process. Whether you need help selecting the right Steel Sheets for your project or require guidance on installation and maintenance, our experts are here to assist you.

We take pride in our reputation as a reliable and trusted supplier in Djibouti. With our extensive network and strong partnerships with leading manufacturers, we can source the highest quality Steel Sheets at the most competitive prices. Our commitment to customer satisfaction has earned us the trust and loyalty of clients across various industries.

Contact us today to discuss your Steel Sheets requirements and discover how we can add value to your projects. We look forward to partnering with you and providing the best Steel Sheets solutions in Djibouti.

When you choose us as your supplier, you can expect competitive prices, prompt delivery, and exceptional customer service. We understand the importance of meeting deadlines and strive to fulfill orders in a timely manner, ensuring that your projects stay on track.

Our team of experienced professionals is dedicated to providing technical support and assistance throughout the entire procurement process. Whether you need help selecting the right Steel Sheets for your project or require guidance on installation and maintenance, our experts are here to assist you.

We take pride in our reputation as a reliable and trusted supplier in Djibouti. With our extensive network and strong partnerships with leading manufacturers, we can source the highest quality Steel Sheets at the most competitive prices. Our commitment to customer satisfaction has earned us the trust and loyalty of clients across various industries.

Contact us today to discuss your Steel Sheets requirements and discover how we can add value to your projects. We look forward to partnering with you and providing the best Steel Sheets solutions in Djibouti.