All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

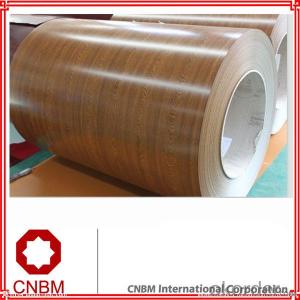

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What are the advantages of using cold-rolled steel in the automotive industry for lightweighting and fuel efficiency?

Cold-rolled steel offers several advantages in the automotive industry for lightweighting and fuel efficiency. Firstly, its high strength-to-weight ratio allows for the creation of lighter components, reducing the overall weight of the vehicle. This, in turn, enhances fuel efficiency as the engine has to work less to propel a lighter load. Additionally, cold-rolled steel has excellent formability, allowing for intricate designs and complex shapes that can further optimize weight reduction without compromising structural integrity. Moreover, its improved surface finish and uniform thickness ensure consistent performance and better aerodynamics, contributing to enhanced fuel efficiency. Overall, the use of cold-rolled steel in the automotive industry brings significant advantages in terms of weight reduction, fuel efficiency, and performance optimization.

Can you elaborate on the environmental sustainability of using cold-rolled steel?

Using cold-rolled steel is considered environmentally sustainable for several reasons. Firstly, the cold-rolling process consumes less energy compared to other steel production methods, resulting in reduced greenhouse gas emissions. Additionally, cold-rolled steel is highly recyclable, meaning it can be reused multiple times without losing its properties, thus minimizing the need for new steel production and reducing waste. Moreover, the durability and strength of cold-rolled steel contribute to longer product lifecycles, reducing the frequency of replacements and decreasing the overall environmental impact. Overall, the environmental sustainability of using cold-rolled steel lies in its energy efficiency, recyclability, and longevity.

How does cold-rolled steel contribute to the production of sustainable and energy-efficient lighting solutions?

Cold-rolled steel plays a crucial role in the production of sustainable and energy-efficient lighting solutions. Its high strength and durability make it an ideal material for manufacturing lighting fixtures that can withstand harsh environmental conditions and last for a long time. By using cold-rolled steel, lighting manufacturers can create more robust and reliable products, reducing the need for frequent replacements and therefore minimizing waste. Additionally, cold-rolled steel can be easily recycled, contributing to a circular economy and reducing the environmental impact of lighting production.

Wholesale Cold Rolled Steel from supplier in Guatemala

Whether you are in need of Cold Rolled Steel coils, sheets, or other related products, we have a wide selection to meet your specific requirements. Our Cold Rolled Steel products are sourced from reputable manufacturers and undergo strict quality control measures to ensure high performance and durability.

In addition to supplying Cold Rolled Steel, we also offer comprehensive quotations and technical support services. Our team of experts is available to assist you in selecting the right Cold Rolled Steel products for your projects, providing accurate and competitive pricing, and answering any technical questions you may have.

As a subsidiary of CNBM, a Fortune Global 500 company, we have the backing and resources to deliver reliable and efficient Cold Rolled Steel procurement services in Guatemala. Our strong market presence and established relationships with local suppliers enable us to offer competitive pricing and timely delivery.

Whether you are a construction company, manufacturing facility, or any other industry requiring Cold Rolled Steel, we are your trusted partner in Guatemala. Contact us today to discuss your Cold Rolled Steel needs and benefit from our expertise and comprehensive services.

In addition to supplying Cold Rolled Steel, we also offer comprehensive quotations and technical support services. Our team of experts is available to assist you in selecting the right Cold Rolled Steel products for your projects, providing accurate and competitive pricing, and answering any technical questions you may have.

As a subsidiary of CNBM, a Fortune Global 500 company, we have the backing and resources to deliver reliable and efficient Cold Rolled Steel procurement services in Guatemala. Our strong market presence and established relationships with local suppliers enable us to offer competitive pricing and timely delivery.

Whether you are a construction company, manufacturing facility, or any other industry requiring Cold Rolled Steel, we are your trusted partner in Guatemala. Contact us today to discuss your Cold Rolled Steel needs and benefit from our expertise and comprehensive services.