All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

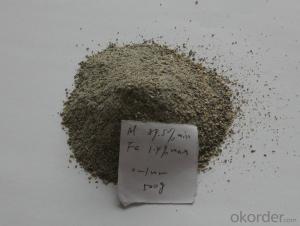

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Q & A

How does alumina content affect the performance of refractory bricks?

The alumina content in refractory bricks significantly affects their performance. Higher alumina content generally improves the refractory bricks' resistance to high temperatures, thermal shock, and chemical corrosion. It also enhances their strength, durability, and ability to withstand mechanical stress. However, excessively high alumina content can lead to decreased thermal conductivity and increased brittleness, which may limit their usage in certain applications.

What are the benefits of using titania as a raw material in refractory production?

There are several benefits of using titania as a raw material in refractory production. Firstly, titania has a high melting point, which makes it suitable for applications in high-temperature environments. It also has excellent thermal stability, meaning it can withstand rapid temperature changes without cracking or deteriorating. Additionally, titania has a low coefficient of thermal expansion, which helps to minimize thermal stress on the refractory material. Moreover, titania exhibits good chemical resistance, making it resistant to corrosion from various chemicals and molten metals. Overall, the use of titania in refractory production leads to improved durability, enhanced performance, and extended lifespan of the refractory products.

What are the raw materials used in the production of alumina refractories?

The raw materials used in the production of alumina refractories primarily include alumina (aluminum oxide), clay, silica, and other additives like binders and fluxes.

Can you explain the role of silimanite in refractory materials?

Silimanite plays a crucial role in refractory materials as it possesses exceptional high-temperature resistance and thermal stability. It is a naturally occurring mineral that is composed of aluminum silicate, making it an ideal ingredient in the production of refractory products. Silimanite's unique properties enable it to withstand extremely high temperatures, making it an excellent choice for lining furnaces, kilns, and other high-heat industrial applications. It also exhibits low thermal expansion and high strength, which helps in maintaining the structural integrity of refractory materials under extreme conditions. Overall, silimanite enhances the performance and durability of refractory materials, ensuring their effectiveness in high-temperature environments.

Wholesale Raw Materials For Refractory from supplier in Iceland

1. High-quality raw materials: We offer a wide range of raw materials for refractory applications, ensuring that you have access to high-quality products that meet your specific requirements.

2. Comprehensive services: Our team of experts is dedicated to providing you with comprehensive services, including sales, quotations, and technical support. We are here to assist you throughout the entire process, from selecting the right materials to providing guidance and support for your projects.

3. One-stop procurement: As a subsidiary of CNBM, a Fortune Global 500 company, we have the resources and capabilities to provide you with convenient and efficient one-stop procurement services. You can rely on us to handle all your raw material needs, saving you time and effort.

4. Extensive experience in the Icelandic market: Our extensive experience in the Icelandic market allows us to offer valuable insights and expertise for your projects. We understand the unique challenges and requirements of the local market and can provide you with tailored solutions that meet your specific needs.

5. Reliable and trusted partnership: We pride ourselves on building long-term relationships with our clients based on trust, reliability, and excellent customer service. When you partner with us, you can be confident that you are working with a reliable and trusted supplier who is committed to your success.

Discover the advantages of partnering with us for all your refractory material needs in Iceland. Contact us today to learn more about our products and services and how we can support your projects.

2. Comprehensive services: Our team of experts is dedicated to providing you with comprehensive services, including sales, quotations, and technical support. We are here to assist you throughout the entire process, from selecting the right materials to providing guidance and support for your projects.

3. One-stop procurement: As a subsidiary of CNBM, a Fortune Global 500 company, we have the resources and capabilities to provide you with convenient and efficient one-stop procurement services. You can rely on us to handle all your raw material needs, saving you time and effort.

4. Extensive experience in the Icelandic market: Our extensive experience in the Icelandic market allows us to offer valuable insights and expertise for your projects. We understand the unique challenges and requirements of the local market and can provide you with tailored solutions that meet your specific needs.

5. Reliable and trusted partnership: We pride ourselves on building long-term relationships with our clients based on trust, reliability, and excellent customer service. When you partner with us, you can be confident that you are working with a reliable and trusted supplier who is committed to your success.

Discover the advantages of partnering with us for all your refractory material needs in Iceland. Contact us today to learn more about our products and services and how we can support your projects.

Hot Search

- Monolithic Refractories in Sri Lanka

- Ceramic Fiber Products in Paraguay

- Refractory Bricks in Italy

- Raw Materials For Refractory in India

- Monolithic Refractories in Chile

- Refractory Bricks in Brazil

- Monolithic Refractories in Oman

- Ceramic Fiber Products in Uzbekistan

- Monolithic Refractories in Comoros

- Refractory Bricks in Samoa