All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What are the environmental benefits of using aluminum coils in construction?

Using aluminum coils in construction offers several environmental benefits. Firstly, aluminum is a highly recyclable material, meaning that it can be reused indefinitely without losing its properties. This reduces the need for extracting and manufacturing new aluminum, leading to significant energy savings and reduced carbon emissions. Additionally, aluminum is lightweight, meaning less energy is required for transportation and installation compared to heavier materials. Furthermore, aluminum is corrosion-resistant, which increases its durability and lifespan, resulting in less frequent replacements and reduced waste. Overall, the use of aluminum coils in construction helps conserve resources, reduce greenhouse gas emissions, and minimize waste generation, making it an environmentally friendly choice.

What is the impact of alloy choice on the cost of aluminum coils?

The impact of alloy choice on the cost of aluminum coils is significant. Different alloys have varying levels of composition and properties, resulting in different manufacturing processes and material costs. Some alloys may be more readily available and easier to produce, making them less expensive. On the other hand, specialized alloys with specific characteristics or higher purity levels might be more expensive due to their limited availability or complex production methods. Therefore, the alloy choice directly affects the overall cost of aluminum coils.

What is the role of aluminum coils in the power generation sector?

Aluminum coils are used in the power generation sector primarily for their heat transfer capabilities. These coils are utilized in various equipment such as condensers and heat exchangers to efficiently transfer heat from one medium to another, facilitating the cooling and condensation processes involved in power generation. Additionally, aluminum coils offer corrosion resistance and lightweight properties, making them suitable for use in power plants where efficiency and durability are crucial factors.

What is the maximum coil weight that can be handled in manufacturing?

The maximum coil weight that can be handled in manufacturing varies greatly depending on the specific equipment and machinery being used. It can range from a few kilograms to several tonnes, depending on the capacity and capabilities of the machinery in question.

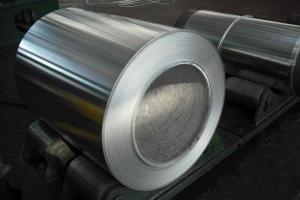

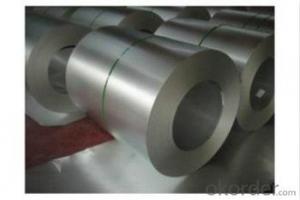

Wholesale Aluminum Coils from supplier in Kyrgyzstan

We are a Aluminum Coils supplier serving the Kyrgyzstan, mainly engaged in the sale, quotation, and technical support services of various Aluminum Coils products in the Kyrgyzstan region. We are a subsidiary platform of the Fortune Global 500 company CNBM, able to provide you with one-stop Aluminum Coils procurement services in the Kyrgyzstan. Not only do we have a wide range of Aluminum Coils products, but after years of market development in the Kyrgyzstan, we can also provide valuable experience for your projects.