All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

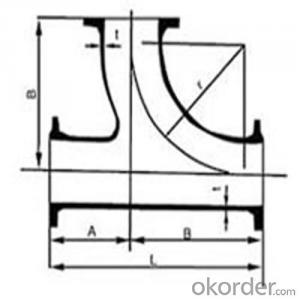

How do you calculate the thickness of a ductile iron reducing tee wall?

To calculate the thickness of a ductile iron reducing tee wall, you need to consider several factors. First, determine the required pressure rating for the tee based on the operating conditions. Next, calculate the maximum internal pressure that the tee will experience. Then, consider the material properties of the ductile iron, such as its tensile strength and yield strength. Using these values, apply the appropriate design formula or code to calculate the required minimum thickness of the tee wall to withstand the pressure. It is crucial to consult relevant design codes and standards specific to ductile iron piping systems for accurate calculations.

How do you join two ductile iron pipes using a ductile iron pipe coupling?

To join two ductile iron pipes using a ductile iron pipe coupling, first, ensure that both pipes are clean and free from any debris or dirt. Next, slide the coupling onto one end of the first pipe, making sure it fits securely. Then, insert the other end of the first pipe into one side of the coupling until it is fully engaged. Repeat the same process with the second pipe, inserting it into the other side of the coupling. Finally, tighten the bolts or clamps on the coupling evenly and firmly using a wrench or a suitable tool to create a strong and watertight connection between the two pipes.

Are ductile iron pipe fittings suitable for trenchless installation methods?

Yes, ductile iron pipe fittings are suitable for trenchless installation methods. They are often used in various trenchless techniques such as horizontal directional drilling (HDD) and pipe bursting due to their high strength, durability, and flexibility. The ductile iron material allows for easy installation and maneuverability underground without compromising the integrity of the fittings.

What are the different types of flange connections used with ductile iron pipe fittings?

There are several types of flange connections commonly used with ductile iron pipe fittings, including threaded flanges, slip-on flanges, weld neck flanges, and blind flanges. Each type has its own unique design and application, offering various levels of ease of installation, strength, and sealing capabilities.

Wholesale Ductile Iron Pipe Fittings from supplier in Morocco

Our team of experts is well-versed in the technical aspects of Ductile Iron Pipe Fittings and can provide guidance on the best fittings for specific projects. We understand the unique requirements of the Moroccan market and can offer tailored solutions to meet our customers' needs.

We have established strong relationships with reputable manufacturers and suppliers, ensuring that our customers receive high-quality products at competitive prices. Our efficient supply chain management system allows us to deliver products on time and in the quantities required.

Furthermore, we offer comprehensive after-sales support, including technical assistance and troubleshooting services. Our dedicated team is available to answer any questions or concerns our customers may have, ensuring their satisfaction with our products and services.

Whether you are involved in water supply, sewerage, or other infrastructure projects, we have the expertise and resources to meet your Ductile Iron Pipe Fittings requirements in Morocco. Contact us today for more information and let us assist you in finding the best solutions for your projects.

We have established strong relationships with reputable manufacturers and suppliers, ensuring that our customers receive high-quality products at competitive prices. Our efficient supply chain management system allows us to deliver products on time and in the quantities required.

Furthermore, we offer comprehensive after-sales support, including technical assistance and troubleshooting services. Our dedicated team is available to answer any questions or concerns our customers may have, ensuring their satisfaction with our products and services.

Whether you are involved in water supply, sewerage, or other infrastructure projects, we have the expertise and resources to meet your Ductile Iron Pipe Fittings requirements in Morocco. Contact us today for more information and let us assist you in finding the best solutions for your projects.

Hot Search

- Ductile Iron Pipes in Eritrea

- Ductile Iron Pipe Fittings in Iran

- Ductile Iron Pipe Fittings in Belgium

- Ductile Iron Pipes in Turkmenistan

- Ductile Iron Pipes in Bhutan

- Ductile Iron Pipes in Cyprus

- Ductile Iron Pipe Fittings in Seychelles

- Ductile Iron Pipe Fittings in Ghana

- Ductile Iron Pipe Fittings in Cuba

- Ductile Iron Pipes in Colombia