All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

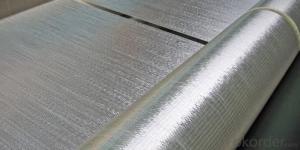

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Fiberglass Chopped StrandView More

Fiberglass Mesh ClothView More

Composite PipesView More

FRP Pultrusion ProfilesView More

Fiberglass Mat TissueView More

Fiberglass FabricsView More

Fiberglass MeshView More

Composite TankView More

Fiberglass Mesh tapeView More

PolymerView More

FRP Roofing PanelView More

Fiberglass RovingView More

Q & A

Are there any specific safety precautions to take while working with fiberglass?

Yes, there are several safety precautions to take while working with fiberglass. It is important to wear protective clothing, such as gloves, goggles, and a respirator, to prevent skin and respiratory irritation. Working in a well-ventilated area or using a ventilation system is crucial to avoid inhaling harmful fumes. Additionally, proper disposal methods for fiberglass waste should be followed to prevent environmental contamination.

Can fiberglass be used in construction?

Yes, fiberglass can be used in construction. It is commonly used for insulation, roofing, wall panels, and as a reinforcement material in concrete structures. It offers good strength-to-weight ratio, durability, and resistance to moisture, chemicals, and fire.

What are the common causes of fiberglass delamination?

The common causes of fiberglass delamination include improper application of resin during manufacturing, exposure to extreme temperatures, moisture penetration, impact or stress on the fiberglass surface, poor maintenance, and aging of the material.

What are the different reinforcement materials used with fiberglass?

There are several reinforcement materials commonly used with fiberglass, including carbon fibers, aramid fibers (such as Kevlar), and glass fibers. These materials are used to enhance the strength, stiffness, and durability of fiberglass composites in various applications.

Are there any disadvantages of using fiberglass supply?

Yes, there are a few disadvantages of using fiberglass supply. Firstly, fiberglass can be quite brittle and prone to cracking or breaking under certain conditions. Secondly, fiberglass can release harmful fumes and particles when cut or sanded, requiring proper safety precautions. Additionally, fiberglass can be more expensive compared to other materials, which may pose a disadvantage for those on a tight budget. Lastly, fiberglass may not be as aesthetically pleasing as other materials, as it can have a rough or industrial appearance.

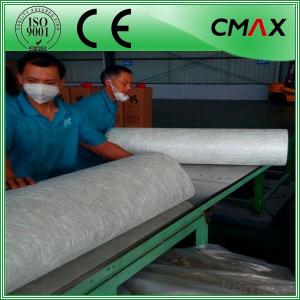

Wholesale Fiberglass Supply from supplier in Rwanda

Whether you are in need of Fiberglass Supply for construction, infrastructure, energy, or any other industry, we have the products and knowledge to assist you. Our team of experts is dedicated to understanding your unique requirements and providing you with the best solutions.

In addition to our wide product range, we also offer competitive pricing, ensuring that you receive the best value for your investment. We understand the importance of cost-effectiveness in your projects, and we strive to help you achieve your goals within your budget.

As a customer-focused company, we prioritize your satisfaction and aim to build long-term relationships with our clients. We are committed to delivering exceptional customer service, including prompt responses to inquiries, efficient order processing, and timely delivery of products.

Furthermore, we are continuously improving our services and expanding our product offerings to meet the evolving needs of the Rwandan market. We stay updated with the latest industry trends and technological advancements to provide you with cutting-edge solutions.

Partner with us for all your Fiberglass Supply needs in Rwanda, and experience the benefits of working with a reliable and experienced supplier. Contact us today to learn more about our products and services.

In addition to our wide product range, we also offer competitive pricing, ensuring that you receive the best value for your investment. We understand the importance of cost-effectiveness in your projects, and we strive to help you achieve your goals within your budget.

As a customer-focused company, we prioritize your satisfaction and aim to build long-term relationships with our clients. We are committed to delivering exceptional customer service, including prompt responses to inquiries, efficient order processing, and timely delivery of products.

Furthermore, we are continuously improving our services and expanding our product offerings to meet the evolving needs of the Rwandan market. We stay updated with the latest industry trends and technological advancements to provide you with cutting-edge solutions.

Partner with us for all your Fiberglass Supply needs in Rwanda, and experience the benefits of working with a reliable and experienced supplier. Contact us today to learn more about our products and services.