All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

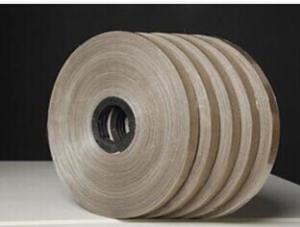

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Q & A

How do alumina-silica refractories differ from silica-alumina ones?

Alumina-silica refractories and silica-alumina refractories differ in terms of the composition ratio of alumina and silica. Alumina-silica refractories have a higher alumina content compared to silica-alumina refractories, where the silica content is higher. This difference in composition affects their thermal and mechanical properties, making them suitable for different applications and operating conditions.

What are the different types of vermiculite used in refractory applications?

There are mainly two types of vermiculite used in refractory applications: raw vermiculite and exfoliated vermiculite. Raw vermiculite is directly mined from the earth and is typically used as an insulating material in refractory products. Exfoliated vermiculite, on the other hand, is processed through a heating and expanding process that causes it to expand into a lightweight, porous material. This expanded vermiculite is commonly used in refractory applications for its excellent thermal insulation and fire resistance properties.

What are the refractory raw materials used in lining ladle well blocks?

The refractory raw materials commonly used in lining ladle well blocks are magnesite, magnesia-carbon, alumina, and graphite.

Wholesale Raw Materials For Refractory from supplier in Sudan

Whether you are in need of raw materials for manufacturing refractory products or require assistance with sales, quotations, or technical support, our company is here to meet your needs. As a subsidiary of CNBM, a Fortune Global 500 company, we have the resources and capabilities to provide you with a comprehensive solution for all your raw material requirements in Sudan.

Our range of raw materials for refractory products includes high-quality materials such as alumina, magnesia, graphite, silicon carbide, and more. These materials are essential for the production of refractory bricks, castables, and other related products. We ensure that our products meet the highest quality standards to guarantee optimal performance and durability.

In addition to supplying raw materials, we also offer sales and quotation services to ensure a seamless procurement process. Our dedicated team will work closely with you to understand your specific requirements and provide competitive pricing for the materials you need. We strive to offer flexible and efficient solutions to meet your project deadlines and budget constraints.

Furthermore, our technical support team is available to assist you with any queries or challenges you may encounter during the production process. We have a wealth of knowledge and expertise in the field of refractory materials, and our team is well-equipped to provide guidance and recommendations to optimize your manufacturing processes.

With our extensive market development experience in Sudan, we can also offer valuable insights and expertise for your projects. We understand the local market dynamics and can provide guidance on product selection, market trends, and regulatory requirements. Our goal is to be your trusted partner and provide you with the necessary support to succeed in your refractory projects.

Contact us today to discuss your raw material requirements and discover how our comprehensive range of products and services can benefit your business in Sudan.

Our range of raw materials for refractory products includes high-quality materials such as alumina, magnesia, graphite, silicon carbide, and more. These materials are essential for the production of refractory bricks, castables, and other related products. We ensure that our products meet the highest quality standards to guarantee optimal performance and durability.

In addition to supplying raw materials, we also offer sales and quotation services to ensure a seamless procurement process. Our dedicated team will work closely with you to understand your specific requirements and provide competitive pricing for the materials you need. We strive to offer flexible and efficient solutions to meet your project deadlines and budget constraints.

Furthermore, our technical support team is available to assist you with any queries or challenges you may encounter during the production process. We have a wealth of knowledge and expertise in the field of refractory materials, and our team is well-equipped to provide guidance and recommendations to optimize your manufacturing processes.

With our extensive market development experience in Sudan, we can also offer valuable insights and expertise for your projects. We understand the local market dynamics and can provide guidance on product selection, market trends, and regulatory requirements. Our goal is to be your trusted partner and provide you with the necessary support to succeed in your refractory projects.

Contact us today to discuss your raw material requirements and discover how our comprehensive range of products and services can benefit your business in Sudan.

Hot Search

- Monolithic Refractories in Liberia

- Ceramic Fiber Products in British

- Refractory Bricks in Uruguay

- Raw Materials For Refractory in Azerbaijan

- Monolithic Refractories in Panama

- Monolithic Refractories in Djibouti

- Refractory Bricks in Russia

- Monolithic Refractories in Spain

- Monolithic Refractories in South Africa

- Raw Materials For Refractory in Latvia