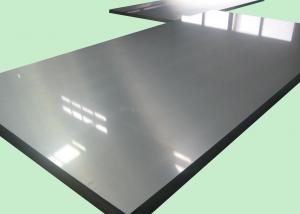

202 2B Stainless Steel Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 2000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

202 Stainless Steel Sheet

1. Chemical composition

2.

|

C |

Si |

Mn |

P |

S |

Ni |

Cr |

|

max0.15 |

max1.00 |

7.50-10.50 |

max0.06 |

max0.03 |

4.00-6.00 |

17.00-19.00 |

2. Mechanical properties

|

Yield Strength |

Tensile |

Elongation |

Hardness (HV) |

Hardness (HRB) |

|

245 |

590 |

40 |

218 |

95 |

3. Standard: AISI, ASTM, GB, EN, DIN, JIS

4. Surface: 2B, NO.1, BA, NO.4, Hairline, SB, Mirror finish, Anti-skid, Cherkered etc.

5. Size: Thickness: 0.3-3mm (cold rolled), 3-40mm (hot rolled)

Width: 1000mm or 1219mm or 1240mm for cold rolled, 1500mm for hot rolled.

Length: As customers' request.

6. MOQ: 1 Ton

7. Payment terms: T/T or L/C

8. Packing: Seaworthy package with wooden or Iron pallets with the paper and the steel strip, or as customers' request.

9. Delivery time: Usually about 7 days after we confirming the order, or according to your quantity.

If you have any question or demand, pls feel free to contact me.

- Q:Can stainless steel strips be used in the electronics industry?

- Yes, stainless steel strips can be used in the electronics industry. Stainless steel is a versatile material that offers several benefits for electronics applications. It has excellent corrosion resistance, which is crucial for protecting electronic components from moisture and other environmental factors. Stainless steel also has good thermal conductivity, making it suitable for heat transfer applications in electronic devices. Additionally, its high strength and durability make it suitable for use in electronic enclosures, connectors, and frames. Overall, stainless steel strips provide a reliable and long-lasting solution for the electronics industry.

- Q:How long do stainless steel strips last?

- Stainless steel strips have a remarkably long lifespan, often lasting for several decades or even longer. The durability and corrosion resistance of stainless steel make it highly resistant to rust, tarnish, and deterioration. The actual longevity of stainless steel strips depends on various factors such as the grade of stainless steel used, the environmental conditions in which they are used or stored, and the level of maintenance they receive. However, with proper care and maintenance, stainless steel strips can last for a lifetime, making them an excellent choice for various applications in industries like construction, automotive, and manufacturing.

- Q:Can stainless steel strips be used for jewelry findings?

- Jewelry findings can indeed utilize stainless steel strips. The widespread preference for stainless steel as a jewelry finding can be attributed to its durability, resistance to corrosion, and affordability. It proves to be a suitable material for various kinds of jewelry findings, including clasps, jump rings, chain links, and earring hooks. Stainless steel strips can be effortlessly manipulated, cut, and polished to produce diverse jewelry components. Additionally, they are accessible in multiple finishes, such as polished, brushed, or matte, thereby offering an extensive array of options for jewelry makers. Moreover, stainless steel jewelry findings are hypoallergenic, rendering them appropriate for individuals with sensitive skin or allergies to other metals. All in all, stainless steel strips represent a versatile and pragmatic choice for jewelry findings.

- Q:How does the price of stainless steel strips vary?

- The price of stainless steel strips can vary based on several factors. Firstly, the grade or quality of stainless steel used in the strips significantly impacts the price. Stainless steel is available in various grades, ranging from the most common 304 and 316 grades to higher-end grades like 430 and 904L, each offering different properties and corrosion resistance. Generally, higher-grade stainless steel strips tend to be more expensive. Another factor that affects the price is the width, thickness, and length of the stainless steel strips. Thicker and wider strips require more raw material and processing, thus increasing the cost. Additionally, the length of the strips can impact the price, as longer strips may require special handling during transportation and storage. The market demand for stainless steel also plays a role in determining its price. When demand is high, prices tend to rise, and when demand is low, prices may decrease. Market dynamics, such as global supply and demand, trade tariffs, and economic conditions, can impact the price fluctuations of stainless steel strips. Lastly, the inclusion of additional services or treatments can affect the price. Surface finishes like brushed, polished, or coated strips may have higher costs due to the additional processing steps involved. Similarly, specialized treatments like heat treatment, edge conditioning, or slitting can also impact the price. Therefore, to determine the exact price of stainless steel strips, it is crucial to consider factors such as the grade, dimensions, market conditions, and any additional treatments required.

- Q:Can stainless steel strips be used in the construction industry?

- Yes, stainless steel strips can be used in the construction industry. Stainless steel is known for its high resistance to corrosion, durability, and strength, making it an ideal material for various construction applications. Stainless steel strips can be used for structural components, such as beams and columns, as well as for cladding, roofing, and facades. They are also commonly used for reinforcement purposes, such as in concrete structures or as support brackets. Additionally, stainless steel strips can be used in the construction of bridges, tunnels, and other infrastructure projects due to their ability to withstand harsh weather conditions and their low maintenance requirements. Overall, stainless steel strips offer numerous advantages in terms of longevity and aesthetic appeal, making them a popular choice in the construction industry.

- Q:Can stainless steel strips be used in the production of HVAC ducts?

- Yes, stainless steel strips can be used in the production of HVAC ducts. Stainless steel is a durable and corrosion-resistant material, making it an ideal choice for HVAC ducts, which are exposed to various environmental conditions. Stainless steel strips can be easily formed and welded to create ducts that meet the necessary specifications and regulatory requirements for HVAC systems.

- Q:Are stainless steel strips resistant to chemicals?

- Yes, stainless steel strips are generally resistant to chemicals. They have a high level of corrosion resistance, making them suitable for various chemical environments. However, the degree of resistance may vary depending on the specific type and grade of stainless steel used.

- Q:How do you determine the mechanical properties of a stainless steel strip?

- To determine the mechanical properties of a stainless steel strip, several testing methods can be employed. One common testing method is tensile testing, which involves subjecting the strip to an increasing load until it reaches its breaking point. During this test, the stress and strain experienced by the strip are measured, allowing for the determination of properties such as yield strength, ultimate tensile strength, and elongation. Another method is hardness testing, which measures the resistance of the stainless steel strip to indentation or penetration by a hard object. Common hardness tests include Rockwell, Brinell, and Vickers hardness tests. The results of these tests provide information about the material's hardness, which is an important mechanical property. Furthermore, impact testing can be conducted to evaluate the toughness of the stainless steel strip. This test involves striking the strip with a pendulum or hammer and measuring the amount of energy absorbed before fracture occurs. The impact test provides insights into the material's ability to withstand sudden loading or shock. Additionally, bending tests can be performed to assess the strip's ductility and flexibility. This test involves subjecting the strip to a specified radius of curvature and observing its behavior. By measuring the amount of force required to bend the strip to a certain degree, its bendability, elasticity, and fracture resistance can be determined. Other mechanical properties, such as fatigue strength, creep resistance, and corrosion resistance, can be evaluated through specialized tests designed to simulate real-world conditions. These tests typically involve subjecting the strip to cyclic loading, elevated temperatures, or corrosive environments and monitoring its performance over time. In summary, determining the mechanical properties of a stainless steel strip involves various testing methods, including tensile testing, hardness testing, impact testing, bending tests, and specialized tests for specific properties. These tests provide vital information about the strip's strength, hardness, toughness, ductility, and resistance to various forms of stress and environmental factors.

- Q:Can 111 stainless steel strips be used in the automotive industry?

- Yes, 111 stainless steel strips can be used in the automotive industry. Stainless steel is widely used in the automotive sector due to its excellent corrosion resistance, high strength, and durability. The specific grade 111 stainless steel is known for its good formability and weldability, making it suitable for various automotive applications. These strips can be used in the construction of car bodies, exhaust systems, fuel tanks, and other components where resistance to corrosion and high mechanical properties are required. Additionally, the use of stainless steel strips in the automotive industry helps enhance safety, improve fuel efficiency, and reduce overall vehicle weight.

- Q:What is the maximum temperature that stainless steel strips can withstand?

- The specific grade of stainless steel determines the maximum temperature that stainless steel strips can tolerate. Stainless steel is generally recognized for its exceptional heat resistance. The commonly employed stainless steel grades, such as 304 and 316, can usually endure temperatures of approximately 1500°F (815°C) without undergoing significant oxidation. Nevertheless, there are specialized stainless steel grades designed for high temperature applications, such as 310 and 321, which can withstand even higher temperatures, up to 2100°F (1150°C). To ascertain the maximum temperature resistance of a particular stainless steel strip, it is crucial to consult the manufacturer or refer to the technical specifications.

1. Manufacturer Overview |

|

|---|---|

| Location | Shandong,China |

| Year Established | 2005 |

| Annual Output Value | Above US$5.3 Million |

| Main Markets | Europe, China |

| Company Certifications | ISO9001:2000 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Tian Jin |

| Export Percentage | 30% |

| No.of Employees in Trade Department | 40 People |

| Language Spoken: | English;Chinese |

| b)Factory Information | |

| Factory Size: | Above 50,000 square meters |

| No. of Production Lines | Above 8 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

202 2B Stainless Steel Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 2000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords