50T*3m heavy duty VC-B manual chain hoist

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 200 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Condition: New

Place of Origin: Hebei, China (Mainland)

Brand Name: CNBM

Model Number: VC-B50T

Usage: Construction Hoist

Power Source: Hand Chain

Sling Type: Chain

Maximum Lifting Weight: 75 tons

Maximum Lifting Height: 12M

Lift Speed: lifting speed

Certification: CE&GS

Warranty: one year

Capacity: 50tons

No. of load chains: 12

Load Chain Diameter: 9mm

Color: red or yellow

Description: VC-A Best price hoist

Test Load: 75T

n.w: 1092kg

Standard lift height: 3m

Main Features

•Superior rigidity makes the hoist dust-proof and water-pfoof;

•Severe environment and work condition are acceptable;

•Simple structure and few components

•Adopt Janpanese FEC chain;

•To greatly enhance the performance of the fatigue and wearresistance.

•Limit protection adevice can avoid overload occerring;

•Hook bolt can prevent the rigging accidently from slip;

•Moter is equipped with thermal protection device;

•limit contactors are set in the machine.

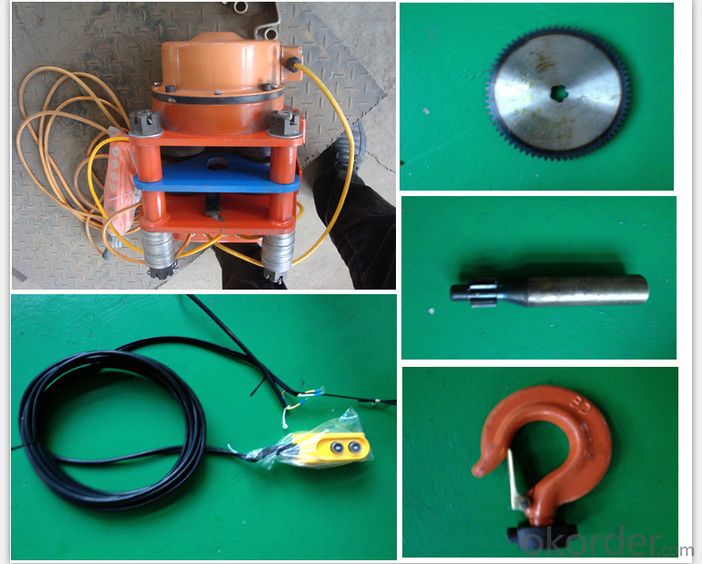

Product Picture

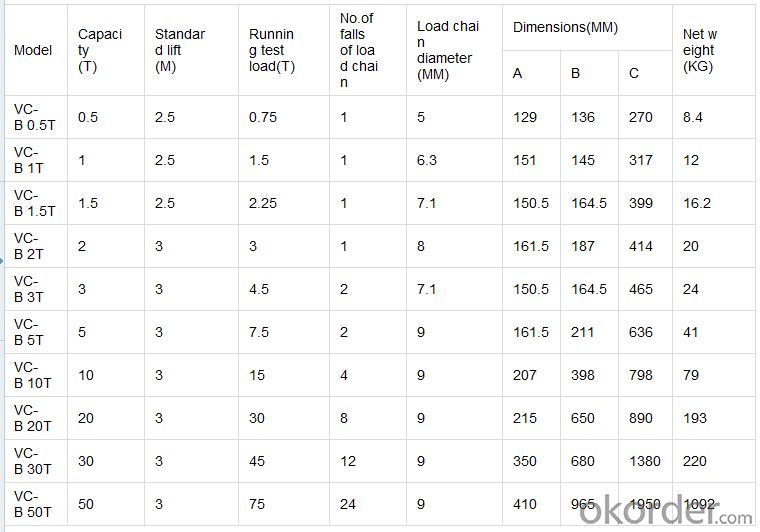

Parameter List

manual chain hoist

1. OEM

2. Certificated,CE,GS,ISO

3. 1 year guarantee

4. manual chain hoist 50 ton

50T*3m heavy duty VC-B manual chain hoist

Main Performances and Technical Specifications

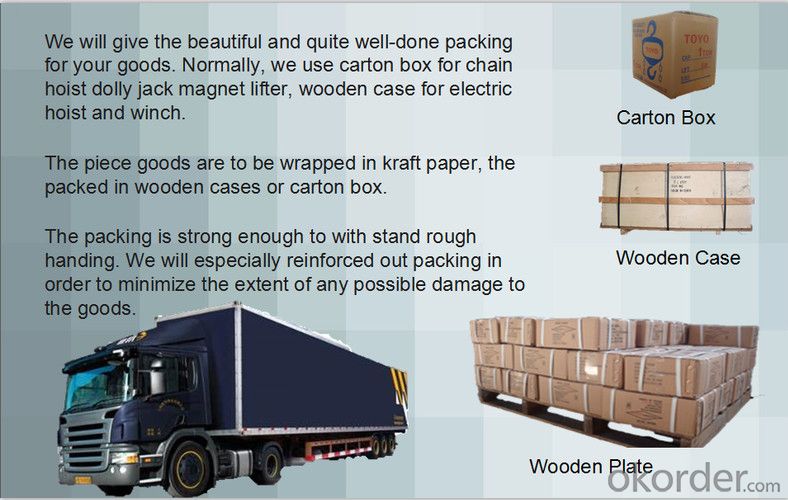

Our Service

1.We can make special sample according to the customer’s requirement.

2. We have more than 20 professional technical team, provide best after-sales service

3. Fast delivery time

4. We have CE, ISO9001 and GS certification.

- Q:What are the specifications for the rigging?

- Because the demand is more difficult to buy, to ask the producer of several wire rope, please note in the purchase, purchase invoice must indicate the name of wire rope, such as phosphate coated wire rope, prevent illegal infringement of their legitimate rights and interests of enterprises, in addition, patent products are generally in the rope on the outer packing of a patent spraying mark, warranty due the main technical indicators, such as the phosphating film type and film weight (have an important impact on the weight of phosphating film size, wear resistance and corrosion resistance of the service life of the wire rope, for reference only)

- Q:What are the installation steps for crane beams?

- Crane operation is relatively dangerous, the installation of crane beam should be standardized to ensure the safety of crane operation. How many points should I pay attention to when installing the crane?:(1) the actual elevation of the corbel should be measured before the installation of the steel crane beam, so that the construction error of the elevation can be adjusted when the crane beam is installed, so as to prevent the error accumulation.The installation sequence of crane beam is as follows: installing crane beam, installing auxiliary truss and installing brake beam.(2) crane shall be used by slings, lashing or reliable clamps. The binding point shall be determined according to the weight and length of the crane beam. Generally, the angle of the sling shall be greater than 45 degrees at the ends of the center of gravity of the crane beam.(3) should be placed after the crane beam, the connecting plate is connected with the fixed edge plate and column crane girder structure, to prevent the crane hook loose after crane girder longitudinal and lateral movement of dumping.(4) crane beam correction should be performed in all bolts after installation, to prevent the installation of bolts when the crane beam shift change; prohibited welding in the crane girder under the flange and web on suspension and fixture.(5) adjust the elevation of the crane beam, correct the center line and span after titanium.

- Q:How to choose the right sling?

- The selection of rigging should be adapted to the kind of articles, environmental conditions and specific requirements.The sling to carry out strict inspection, in accordance with safety color to use, if found damaged sling can not be reused, need for scrap processing.The slings used for lifting operations must be of the same length.The sling shall not exceed its rated lifting capacity, and the sling shall not exceed its maximum safe working load.

- Q:What are the selection principles for lifting cranes?

- Selection should take into account the performance of the crane (ie operation capacity), ease of use, hoisting efficiency, hoisting capacity and duration requirements.

- Q:What is the safety factor of the wire rope as a motor lifting equipment, slings and slings?

- 4. coated steel wire rope, the carbon steel wire rope based on the rope or rope coated with polyethylene or polypropylene5. smooth wire rope, in 1834 the British began production in China in 1939 started production in Tianjin No.1 steel wire rope factory, with the phosphating coating steel wire rope into the market size gradually increased, will be fully replace phosphating coating steel wire rope.

- Q:Ceiling installation does not allow the use of air nails?

- Connection of hanging cup, sling and structural layerOperation method: (1) the main consideration connected with embedded parts and transition piece.In the first layer in embedded iron or wood brick (except water brick). The location shall be accurate and adequate adjustment should be made.The transition in the iron and wooden fittings, so as to adjust the mindware error, and mindware nail, screw, welding, wear.The suspender and the sling are connected with the transition connecting piece.

- Q:Is rope sling good business and high profit?

- 1. phosphating coating steel wire rope, steel wire by manganese or zinc manganese phosphating, corrosion resistance and wear resistance steel rust resistance comprehensive jump, life is the same structure of plain steel wire rope 3 times (note the use of zinc phosphating and drawing rope with distinction, although Tianjin bonderizing Jiangsu have been a number of production enterprises, there is still a shortage of supply and demand)2. galvanized steel wire, hot-dip galvanized and galvanized3. stainless steel wire rope, 304 or 316 stainless steel4. coated steel wire rope, wire rope on the basis of the outer coating of polyethylene or polypropylene5. smooth steel wire rope, will be phosphating coating steel wire rope completely eliminated.

- Q:Does the pressing rope have any influence on the tension value of the wire rope?

- Lifting equipment commonly used wire rope varieties of phosphating coating steel wire rope, galvanized steel wire, stainless steel wire rope or coated steel wire rope.

- Q:Which brand is better for imported rigging?

- CarlStahl set up Chinese branch in Hangzhou in 2006, mainly engaged in CarlStahl brand heavy duty crane, lifting fixture, spring balancer, hoist, crane beam, lift hook, rope, wire rope, tie, round sling hoisting products etc..

- Q:Requirements and matters needing attention in hoisting

- When the equipment is mounted on a frame or a building, its strength and stability shall meet the requirements of the installation conditions. In equipment installation and location according to the requirements of the drawings are tightly connected or welded, meet the design requirements of the strength and has stability, can be decoupled, otherwise they should be temporary fixed 1. security measures, to prevent the crane from tilting measures (1). The lifting scene road must be smooth solid backfill, soft soil should be processed. If the soil is soft, roads should be paved separately. Parking crane is not working on a slope, also does not allow the crane two side high.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

50T*3m heavy duty VC-B manual chain hoist

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 200 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches