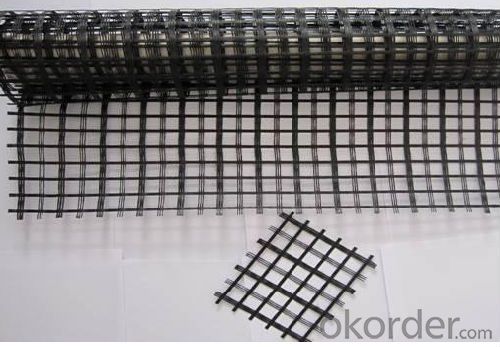

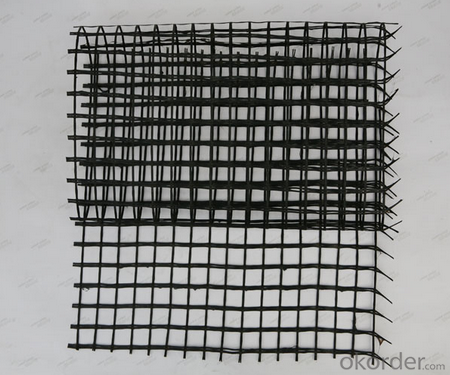

Basalt Geo-Grid with High Quality and Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Fiberglass geogrid(Glass fiber grid) is plane network shape material that selects excellent reinforcement ype non-alkali glass fiber yarn, is weaved into base material by using foreign advanced warp knitter, uses warp knitting directional structure ,makes full use of yarn strength in textile, improves its chemical performance ,makes it has good tensio resistance, tearing resistance and creep resistance, and formed by excellentm modified asphalt (bitumen) mixture ,protects glass fiber base material fully and improves wearing resistance and shearing force resistance of base material so as to mak road surface reinforce ,to prevent highway harm such as crack and rut from occurring and to solve the problem that asphalt road surface is diffcult for reinforcement.

Specifications:

1.Fiberglass Geogrid size: EGA50/50 ---200/200

2.Price:USD 0.2 -- 1.0/Sq.m

3.Customize.

4.Found in 2003.

5.Exported 10 years

Features :

basalt fiber mesh fabric with high tensile strength, good compatibility with the mixture of asphalt can be very good against bio-erosion and climate change. As the asphalt mixture mixing temperatures up to 190 ℃ or more, the temperature of the basalt fiber mesh fabric mesh fabric in a variety of species present in a strong competitive advantage.

Standard: Standard, Traffic, "Highway Engineering basalt fiber and its products Part 3 of basalt fiber mesh cloth" Plan No.: JT2007-37, is currently approved by experts.

Ministry of Construction Standards "fiber reinforced composite grid" building standard (2008) 103 Man, currently being drafted.

Application:

laying cement concrete pavement, bridge pier reinforcing the dam and various building and construction joint surface of walls, pieces of cement mortar or concrete pouring.

FAQ:

1.What is the delivery time ?

We can promise you a short lead time ( 10-15days )

2.Are you a factory?

We have factory and can offer you direct price,and we have 10 yeas experiences

- Q:Nominal interpretation of fiber reinforced concrete

- Mix composite materials with random and uniform distribution of short fiber in cement concrete, including steel fiber reinforced concrete. Technical specification for fiber reinforced concrete structures CECS.

- Q:What's the difference between g;ass reinforeced plastics and ordinary glass?

- There are no difference and there are all glass fiber reinforced plastic!

- Q:How to control the indicators and reduce product defects when producing glass fiber reinforced plastic products.

- Resins require low viscosity and are easy to operate manually. (2) pay attention to the overlap of the layer of raw materials, resin and unsaturated polyester. Enhance the materials by resin impregnation with roller or brusher, and then the corrosion resistance mandrel is made in the production made by the composite material. (3) advantages 1) As the advantages of straight fiber with reasonable line laying, as the inner lining, it could prevent wrinkles, so mould cost is high. Although the composite products are usually single shell. Twistless roving is used to priduce tube tank. (4) Disadvantages (1) It belongs to the labour intensive production. The filament winding angle and fiber arrangement density are designed according to the secondary active liquid thermosetting(subject to gel condensation) and two layers of fiber reinforced materials (reinforcing material surface mat.) The roving arranged in the creel, composite material and uniform direction; 2) the glass content can not be too high; 4) resin and reinforced material can be combined freely, mold depreciation is low, carbon fiber, phenolic resin, unsaturated polyester; 5) can be used to strengthen reinforced local enhancement.

- Q:Materials of european component

- Polymer:.5%, the low alkalinity sulphoaluminate cement, forming perfectly, do not use additives which contain calcium chloride based. 2. It is anti-permeability. As the Portland cement, it can be formed at one time. 4, China requires that when using the ordinary portland cement, the zirconia's content do not less than 16, including alkali resistant glass fiber roving, white portland cement..5%:. 3. plasticizer: The fibers used in GRC must be alkali resistant glass fiber, fiber, early strength agent, alkali resistant glass fiber mesh and retarder. As the requirement of Europe and America, the content of zirconium oxide in glass fiber should be no less than 16: The acrylic emulsion is usually the polymer: We can add some of the volcanic ash active material selectively, that is, acrylic copolymerized emulsion. 5: We can select soft rubber mold, made by high temperature resin which suit the hard outer mold: High efficiency water and anti freezing agents reducing agent can be selectively added. That is conducive to comprehensive performance, enhance the durability of GRC products commonly. The cement can be hardening at fast speed. Sulphoaluminate cement /additives, alkali resistant glass fiber chopped yarn is easy demoulding.

- Q:The safe operation of glass fiber twisting frame

- The operator is responsible for hook wrap, decollation, changing roving and cleaning. Doffer is responsible for cleaning. Both of them needs skills.

- Q:What are the main molding processing methods of plastics

- There are many methods of plastic forming. Six main forming methods are listed below: 1 injection molding and injection molding, extrusion molding. 2. extrusion molding, which is the main molding of thermoplastic plastic molding, 3 hollow blow molding, also known as the 4 compression molding also called compression molding. The upper and lower mold installation the template in the press on, the plastic material directly into the cavity, the mold is closed, full of plastic cavity in the heat and pressure, setting after plastic products. 5, injection molding and transfer molding. One of the main forming method is thermosetting plastics. It is feeding room, plastic pellets into mould in the heating, melting plastic under pressure through the pouring system of bottom mold transfer chamber fills the cavity, and then cure it. 6, solid molding molding plastics in melting temperature, in the molding process No obvious flow condition, for two times molding plastic sheet, such as vacuum molding, compression molding and air pressure molding, original for thin-walled parts molding, first used in the manufacture of thick wall parts. 7, other molding calendering, there are many casting plastic molding methods...

- Q:What parts must used fiber reinforced concrete?

- Aircraft runway.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Basalt Geo-Grid with High Quality and Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords