Calcium Silicate Board for Drywall Partition

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

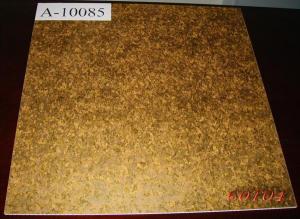

Specifications

1.100% non-asbestos

2.Bending strength 13MPa

3.Nonflammability A grade

4.Waterproof / fireproof

Calcium Silicate Factory

Fire Rated Calcium Silicate Board

Calcium silicate board is made from wood lengthy fiber, concrete

and silicon sand, under the high pressure water vapor process, therefore, it performs

well in humidity durability, force resistance and fire proofing. Yute fiber

cement board is suitable for indoor partition, ceiling and decoration.

CMAX fiber cement board presents the art of Germany know-how as a high quality

building material. It contains inorganic raw materials such as cement, silica powder

and reinforced cellulose fiber as the main materials. All CMAX boards are

autoclaved to become stable product. CMAX fiber cement board does not contain

any of asbestos fiber; however, it has strong bending strength like those with

asbestos.

CMAX fiber cement board can be applied not only for the interior use but also

for the outdoor wall system. It has low water absorption rate and high impact resistant

ability. These good advantages make it suitable for any purposes of applications.

Specifications:

1) 100% non-asbestos

2) Density: 1,000 - 1,400kg/cbm

3) Coefficient of thermal expansion: 0.24W/MK (JC/T54)

4) Bending strength: over 13MPa (GB/T7019-1997)

5) Linear expansion rate: 0.1%

6) Water absorption rate: less than 0.19% (GB/T7019-1997)

7) Water penetration rate: 0%

8) Water content: 10%

9) Incombustibility according to CNS 6532 and BS 476

10) Two point five three hours of fire rating for (6mm wall system with W-CSP concrete)

11) Radioactivity: standard (GB6566-2000)

12) Characteristic: nonflammability A grade (GB-8624-1997)

Features:

1) Heat insulation, stability, damp-proof, sound insulation, fire resistance and

light weight

2) The wall is solid and firm inside, and resistant to impact pressure

3) Painting, tiling and nailing is possible in the new system .

4) Noise reduction can be up to 46dB

5) Good efficiency

6) Working environment can keep it dry and clean for better management

7) Certificates with 2.53 hours of fire rating.

- Q:Do the TV backdrop, there is a part of the original window, now sealed with calcium silicate board.

- You can use wallpaper, marble, diatom mud will do. If the use of marble recommended dry hanging, because the grass-roots calcium carbonate plate has a water absorption, can not achieve the condensation strength.

- Q:Will silicon calcium plate become moldy?

- Calcium silicate mainly composed of calcium silicate, composed of siliceous materials (diatomaceous earth, bentonite, quartz powder, etc.), calcium material, reinforced fiber as the main raw material, after pulping, billet, steam curing, And other processes made of lightweight plate.

- Q:Calcium silicate board material production methods which

- Calcium silicate (microporous calcium silicate) materials, calcium silicate board production methods are static autoclave, dynamic hydrothermal synthesis and secondary reaction method. At present, most of the domestic production of static technology, raw materials and auxiliary materials will be a certain proportion of ingredients, adding the right amount of water, stirring conditions heated to a certain temperature for gelation, and then by molding, autoclaved curing, drying the existing calcium silicate board Insulation materials products. Static method used diatomite for siliceous materials, calcareous materials and more lime. The process is simple and low cost, but in the production requires large capacity autoclave, and the reaction is not complete, the main form of tourbillate to calcium carbonate board, the use of low temperature (<650 degrees Celsius), it is difficult to produce light, Light high strength products.

- Q:Calcium silicate board and magnesium silicate board which is better

- Magnesium silicate board using magnesium oxide as the main raw material, produced by the decorative materials, the advantages are: light, good toughness; drawback is: low strength, low moisture resistance, soaked after the water marinade, destruction of the wall surface The

- Q:Two layers of calcium silicate board in the middle of what kind of sound insulation board

- Calcium silicate composite rockwool sound insulation board, but now with less, mainly out of environmental protection, the use of area considerations.

- Q:Moisture gypsum board is not calcium calcium board?

- Moisture-resistant gypsum board is made of waterproof protective paper inside or ordinary gypsum pulp

- Q:Calcium sulfate anti-static flooring and calcium silicate board What are the differences

- This floor is generally with HPL melamine veneer, good wear resistance. And because the rough surface of the substrate is easy to glue, bonding is very strong, never crack. In addition, can also be made of core-board, plate-based six sides are galvanized sheet, so that can be used as a network floor, for carrying high demand for office space. This is a "wide applicability" of the product, can be used for all aerial flooring occasions, especially carrying high requirements of the engine room, office space, and it is not demanding maintenance, long service life.

- Q:My home decoration ceiling, decoration company reported is easy to licensing calcium carbonate board to do smallpox, how ah, environmental protection? And the concrete board to identify it

- Calcium silicate board is now a lot of domestic asbestos, will cause lung cancer and mesothelioma, carcinogenic probability is very large, and now engage in decoration are generally funny (there are some companies do not have the ability to produce asbestos calcium silicate board With asbestos board posing), give you with asbestos calcium silicate board

- Q:Calcium silicate board surface smooth it? Waterproof? Can I use this board to do the outdoor door?

- Calcium silicate board processing generally there are two, according to the customer requirements for flatness can be divided into sanding and not sanding. Sanding is the correction of flatness. So that there is no problem flatness.

- Q:What is the difference between perforated calcium silicate wallboard and gypsum board?

- Silicon calcium board was first used in high temperature furnace insulation. Such as "in order to improve the quality of shaft kiln clinker material, easy to coal blending and reduce clinker burning coal consumption, we must strengthen the kiln kiln body insulation.Often the practice is to use the internal insulation method, refractory layer, the total thickness of the insulation layer should be ≥ 650mm, near the kiln wall should be added ≥ 60mm calcium silicate board or aluminum silicate fiber mat ".

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Calcium Silicate Board for Drywall Partition

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords