Concrete Pump Truck Parts Bend ZX-HD DN125 R500 45DRG

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Widely used on concrete pump truck, concrete placing boom, trailer concrete pump etc, for concrete delivery bend connection.

Our concrete pump bends have been successfully exported to many countries from 1998, Our main markets as below: Middle East, Southeast Asia, America, Brazil, Italy, Russia, South Africa etc.

Main Product Features:

1. Mainly adopt carbon steel high wear resistant steel, and other material upon your request.High Chromium and manganese content, which enables a higher wear resisting ability and longer lifetime.

2. Hydraulic tester & artificial detection./ Uniform baking finish. Seaworthy packing or as customers’ request.

3. Possess quality certification of ISO 9001:2000. Can pass CE test.

4. We have been providing parts for nearly ten years, and cooperating with the agent of the world famous brand, possess near every kind of bend in the market.

5. OEM service available.

6. Fitting to PUTZMEISTER, SCHWING Sany, Zoomlion concrete pumps

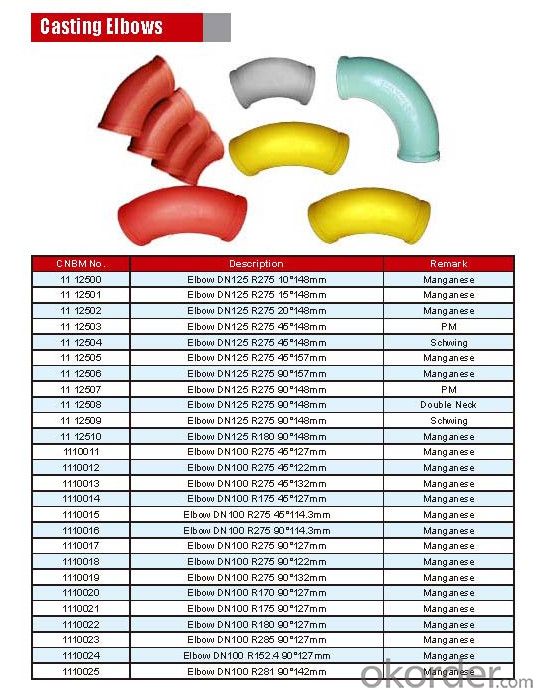

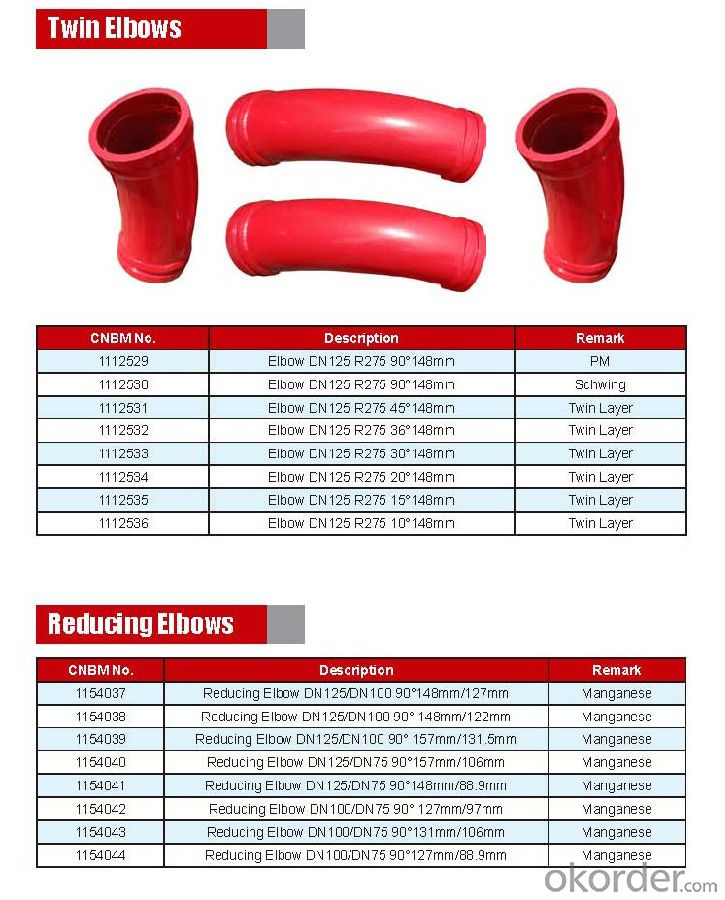

Product Specifications:

Technical: Casting

Radius: 500mm

Degree: 45

Material: Mn13-4

Characteristics: According to our technology, the casting bends also has high working pressure and burst pressure.

Package: PP woven bag and plastic cap

FAQ:

Q1: How to confirm that your bends could be used in our pump?

A1: We have been providing parts for nearly ten years, and cooperating with the agent of the world famous brand, possess near every kind of bend in the market. What is more, we can produce as the customers’ request with drawing provided.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 5-15 workdays.

Q4: If we can produce some Concrete Pump Truck Parts according to customers request?

A4: Yes, we can produce Concrete Pump Truck Parts according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

Other Products:

- Q:Are there any specific guidelines for the selection and installation of hydraulic components in concrete pump spare parts?

- Concrete pump spare parts have specific guidelines for the selection and installation of hydraulic components. When choosing these components, it is important to consider factors like the maximum operating pressure, flow rate, and compatibility with the existing hydraulic system. First and foremost, it is crucial to ensure that the selected hydraulic components can handle the maximum operating pressure of the concrete pump. This includes components such as hydraulic cylinders, valves, and pumps. To ensure their durability and longevity, it is advisable to choose components with a higher pressure rating than that of the concrete pump's operating pressure. Additionally, the flow rate of the hydraulic components must match the requirements of the concrete pump system. Hydraulic pumps and valves need to provide sufficient flow to effectively operate the concrete pump. Factors such as the size of the concrete pump, desired output capacity, and specific pumping requirements should be taken into consideration. Furthermore, compatibility with the existing hydraulic system is vital for the smooth operation of the concrete pump. It is important to select hydraulic components that are compatible with the system in terms of fittings, connections, and overall design. Seeking guidance from the manufacturer's guidelines or professional advice is recommended when selecting and installing hydraulic components in concrete pump spare parts. Moreover, proper installation is essential to ensure optimal performance and safety of the hydraulic components. Following the manufacturer's installation instructions and guidelines is highly recommended. The installation process should include proper alignment, secure mounting, and appropriate sealing of the components to prevent any leaks or failures. In conclusion, there are specific guidelines for selecting and installing hydraulic components in concrete pump spare parts. Considering factors like maximum operating pressure, flow rate, compatibility, and following proper installation procedures can help ensure the efficient and safe operation of the concrete pump system.

- Q:What is the purpose of a concrete pump hydraulic accumulator bladder?

- The purpose of a concrete pump hydraulic accumulator bladder is to store and release hydraulic energy within a concrete pump system. The bladder acts as a flexible barrier between the hydraulic fluid and a gas or air chamber. When hydraulic fluid is pumped into the bladder, it compresses the gas or air inside, storing potential energy. This energy can then be released when needed to power the hydraulic system, providing a surge of pressure and flow to ensure efficient and controlled movement of the concrete. The hydraulic accumulator bladder serves several important functions in a concrete pump system. Firstly, it helps to smooth out and regulate the flow of hydraulic fluid, reducing pressure fluctuations and ensuring a steady and consistent supply of power to the pump. This helps to prevent damage to the pump components and ensures a more reliable and efficient operation. Additionally, the bladder helps to compensate for variations in demand. As the concrete pump operates, there may be times when the demand for hydraulic power exceeds the supply. In such cases, the bladder can release the stored energy to meet the increased demand, providing a temporary boost to the hydraulic system. This helps to maintain a consistent and continuous flow of concrete, even during peak demand periods. Furthermore, the hydraulic accumulator bladder can also act as a safety device. In the event of a sudden pressure surge or spike in the hydraulic system, the bladder can absorb and dampen the excess pressure, preventing damage to the pump or other components. This helps to protect the equipment and ensure the safety of the operators. In summary, the purpose of a concrete pump hydraulic accumulator bladder is to store and release hydraulic energy, smooth out and regulate hydraulic fluid flow, compensate for variations in demand, and act as a safety device. By performing these functions, the bladder helps to optimize the performance and efficiency of the concrete pump system, ensuring a reliable and controlled movement of concrete.

- Q:How often should concrete pump cylinders be inspected and replaced?

- Concrete pump cylinders should be inspected regularly, ideally on a daily basis, to ensure they are in proper working condition. The frequency of replacement depends on several factors including the intensity of usage, maintenance practices, and the quality of the concrete being pumped. Generally, concrete pump cylinders should be replaced when they show signs of significant wear and tear or when they no longer meet the required performance standards.

- Q:How to calculate the power of concrete pump motor?

- Second, the amount of transport is the amount of export pressure is determined,

- Q:What is the function of a concrete pump hydraulic accumulator?

- The function of a concrete pump hydraulic accumulator is to store energy from the hydraulic system and release it when needed, providing a surge of power to the concrete pump. This helps to maintain a consistent and smooth flow of concrete, preventing any disruptions or blockages in the pumping process.

- Q:What are the different types of concrete pump hopper vibrators?

- On the market, one can find various concrete pump hopper vibrators. Their purpose is to ensure a smooth flow of concrete through the hopper and into the pumping system. 1. Electric Vibrators: The most commonly used hopper vibrators are powered by electricity. They are typically attached to the hopper's side and employ an electric motor to generate vibrations that facilitate the movement of concrete. 2. Pneumatic Vibrators: These vibrators rely on compressed air as their power source and are commonly employed in situations where electricity is not readily accessible. By utilizing air pressure, they create vibrations that aid in the continuous flow of concrete. 3. Hydraulic Vibrators: Larger concrete pumping systems often utilize hydraulic vibrators, which derive their power from hydraulic fluid. These vibrators can be more robust than their electric or pneumatic counterparts, making them suitable for heavy-duty applications. 4. Rotary Vibrators: To move the concrete, these vibrators employ an eccentric weight that spins, resulting in vibrations. They are frequently used when a high frequency of vibration is necessary. 5. Turbine Vibrators: These vibrators employ a turbine mechanism to generate vibrations. They are commonly employed when a low frequency of vibration is desired. 6. Ball Vibrators: These vibrators use a ball housed within a casing to generate vibrations. They are frequently utilized in smaller concrete pumping systems and can be easily mounted onto the hopper. In conclusion, the choice of the most suitable concrete pump hopper vibrator for a specific application depends on various factors, including the size and type of the concrete pumping system, the desired frequency and intensity of vibration, and the availability of power sources.

- Q:How can a malfunctioning control box affect the pump's operation?

- A malfunctioning control box can disrupt the pump's operation in several ways. It may fail to send accurate signals to the pump, leading to incorrect speed or pressure settings. This can result in inadequate water flow or excessive pressure, affecting the pump's efficiency and potentially causing damage. Moreover, a malfunctioning control box might also cause the pump to start or stop unexpectedly, leading to inconsistent operation and potential system failures.

- Q:How often should concrete pump electric motors be inspected and maintained?

- Concrete pump electric motors should be inspected and maintained regularly to ensure their optimal performance and longevity. It is recommended to have them inspected at least once a year or every 500-1000 operating hours, whichever comes first. Additionally, regular maintenance should be carried out based on the manufacturer's guidelines and recommendations. This may include checking and replacing worn-out parts, lubricating moving components, cleaning dust and debris, and inspecting electrical connections for any signs of damage or loose connections. Adhering to a regular inspection and maintenance schedule will help prevent potential breakdowns, increase the lifespan of the motor, and ensure the concrete pump operates efficiently.

- Q:Can I get spare parts for concrete pump hydraulic cylinders and valves?

- Yes, you can definitely get spare parts for concrete pump hydraulic cylinders and valves. There are numerous companies and suppliers that specialize in providing spare parts for construction equipment, including hydraulic cylinders and valves for concrete pumps. These spare parts can be easily sourced online or through local distributors. It is important to ensure that you provide accurate information about the make and model of your concrete pump to ensure compatibility and proper functioning of the spare parts. Additionally, it is advisable to choose reputable suppliers who offer high-quality, genuine spare parts to guarantee optimal performance and durability.

- Q:What are the different types of concrete pump hopper agitator blades?

- In the construction industry, there exists a variety of concrete pump hopper agitator blades. These blades have different designs and functions, all aimed at efficiently mixing and agitating the concrete mixture in the hopper. By achieving a consistent and homogeneous mixture, the concrete can be pumped onto the project site effectively. 1. Paddle Blades: The most commonly used agitator blades in concrete pump hoppers are paddle blades. These blades have a flat, paddle-like design that effectively mixes the concrete ingredients. They are typically made of high-quality steel or hardened rubber to ensure durability and optimal performance. 2. Helical Blades: Another type of agitator blade is the helical blade, which has a spiral shape. This design creates a gentle, swirling motion within the hopper, preventing the formation of lumps and ensuring a smooth and well-mixed concrete mixture. 3. Ribbon Blades: Thin and flat, ribbon blades resemble ribbons and are placed vertically in the hopper. They rotate along their axis to thoroughly mix the concrete ingredients. Ribbon blades are known for their ability to prevent clogging and improve the efficiency of concrete pumping. 4. Fan Blades: With a unique fan-shaped design, fan blades create a powerful airflow within the hopper to agitate the concrete mixture. This type of blade is particularly effective in preventing the segregation of concrete ingredients and maintaining a consistent mixture. 5. Tine Blades: Tine blades feature multiple prongs or tines extending from a central hub. They provide a more aggressive agitation action, making them suitable for mixing heavier concrete mixes or those containing large aggregates. The selection of agitator blades depends on various factors, such as the type of concrete, desired consistency, and specific project requirements. It is crucial to choose the appropriate blade type and perform regular maintenance to optimize the performance and lifespan of the concrete pump hopper agitator.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Concrete Pump Truck Parts Bend ZX-HD DN125 R500 45DRG

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords