fiber glass wool blanket, glass wool price, fiber glass wool insulation

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Glass Wool Blanket:

Vacuum compressed packing in plastic PP/PE bag and plastic woven bag.

To increase loading quantity and reduce cost of transportation, all exported glass wool blanket would be packed

vacuum. However, due to excellent rebound property, when reach to destination our glass wool will rebound

almost to the original level within 1day after been unpacked.

At the system HOT END, the raw materials are dosed, mixed, melted, fiberized, impregnated with a special binder and formed into a primitive mat of very fine fiber glass. Continuous conveyors transport the mat to the COLD END of the plant for binder polymerization. The product is then cut to shape and packed for shipping.

2.Main features of Glass Wool Blanket:

1) Heat insulation and heat preservation, sound adsorption and noise reduction

2) Low slag indusion content, thin and long inner fiber

3) Thermal stability, stable and high efficiency for a long time

4) High temperature heat-stability, durability, high temperature shrinkage resistance

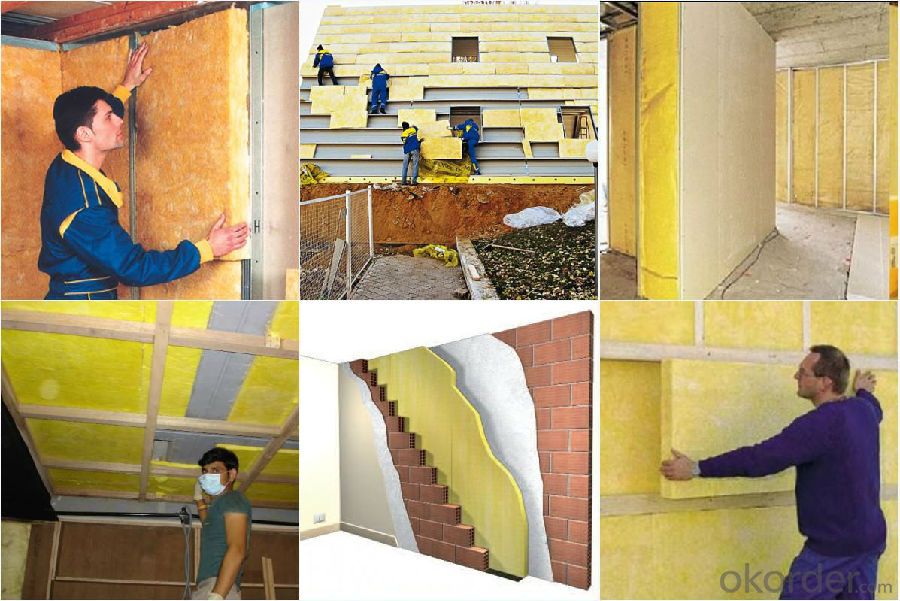

3.Glass Wool Blanket Images:

4. Glass Wool Insulation Blanket Technical Parameters:

Property | High/low temperature resistance, oil and fuel resistance, weathering resistance, O zone resistance etc. |

Shape | According to your requirement. |

Color | Any color is available ,according to your requirements. |

Material | NBR, CR, SBR, EPDM, IIR, NR, EP, Silicone, VITON etc. |

Hardness | 30-90ShoreA |

Delivery | In 10 days |

Packing | Plastic bag & carton box or according to your requirements. |

Application | Electronic field, industrial machine & equipment, house-hold appliance, telecommunication, automobile, medical equipment industry etc. |

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Glass Wool Blanket is one of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q:Are there any health risks associated with fiberglass mat tissue?

- Yes, there are some health risks associated with fiberglass mat tissue. Fiberglass contains tiny fibers that when inhaled can irritate the respiratory system and potentially cause lung damage. Prolonged or repeated exposure to fiberglass fibers can also lead to a condition called fiberglass dermatitis, which causes skin irritation and itching. Therefore, proper precautions such as wearing protective clothing and masks should be taken when handling fiberglass mat tissue to minimize the health risks.

- Q:How is fiberglass mat tissue used in the production of storage sheds?

- Fiberglass mat tissue is commonly used in the production of storage sheds due to its excellent strength and durability properties. It is typically employed as a reinforcement material to add structural integrity to the shed's walls, roof, and floor. During the manufacturing process, fiberglass mat tissue is often applied to the shed's exterior and interior surfaces. It is first impregnated with a resin, usually polyester or epoxy, which acts as a binder. The resin-soaked fiberglass mat tissue is then layered onto the shed's panels or molds. Once in place, the resin is cured, either through the application of heat or a chemical reaction, which hardens the material. This process creates a rigid, lightweight, and weather-resistant composite structure that is highly resistant to cracking, warping, or rotting. The fiberglass mat tissue serves as a reinforcing layer, providing added strength and stability to the shed. It helps distribute loads evenly across the structure, making it more resistant to impacts or external forces. Additionally, the fiberglass mat tissue helps prevent the shedding of particles, enhancing the overall appearance and cleanliness of the shed. Furthermore, fiberglass mat tissue offers excellent thermal insulation properties. This insulation helps regulate the temperature inside the shed, keeping it cooler during hot summer months and warmer during the colder seasons. It also aids in reducing energy costs by minimizing heat transfer. Overall, the use of fiberglass mat tissue in the production of storage sheds significantly enhances their durability, strength, and insulation capabilities. It ensures a long-lasting and reliable structure that can withstand various weather conditions while providing a comfortable and secure storage space.

- Q:Can fiberglass mat tissue be used for composite pipe manufacturing?

- Yes, fiberglass mat tissue can be used for composite pipe manufacturing. Fiberglass mat tissue is a type of reinforcement material that is commonly used in the production of composite pipes. It provides strength and durability to the pipes, making them suitable for various applications. The fiberglass mat tissue is typically impregnated with a resin, such as polyester or epoxy, which helps to bind the fibers together and create a solid structure. This reinforcement material is known for its lightweight properties and excellent corrosion resistance, making it an ideal choice for composite pipe manufacturing. Additionally, fiberglass mat tissue can be easily molded into different shapes and sizes, allowing for the production of pipes with varying diameters and lengths. Overall, the use of fiberglass mat tissue in composite pipe manufacturing offers numerous advantages, including enhanced strength, durability, and resistance to harsh environmental conditions.

- Q:Can fiberglass mat tissue be used for insulation in cryogenic applications?

- Indeed, insulation in cryogenic applications can be accomplished using fiberglass mat tissue. Renowned for its exceptional thermal insulation properties, fiberglass is a versatile substance. Its capability to diminish heat transfer is heightened due to its low thermal conductivity. Consequently, it is remarkably suitable for cryogenic applications that necessitate the maintenance of exceedingly low temperatures. Furthermore, fiberglass possesses non-combustible qualities and does not absorb moisture, rendering it the perfect choice for cryogenic environments. By implementing it as an insulation layer, fiberglass can effectively impede heat transfer and sustain the desired low temperatures in cryogenic storage tanks, pipes, and other related equipment.

- Q:Is fiberglass mat tissue suitable for marine repairs?

- Yes, fiberglass mat tissue is suitable for marine repairs. It is commonly used in boat and yacht repairs due to its excellent strength, durability, and resistance to water and corrosion. Additionally, fiberglass mat tissue is easy to work with and can be used for various applications such as hull, deck, and structural repairs in marine environments.

- Q:Can fiberglass mat tissue be used for roofing?

- Yes, fiberglass mat tissue can be used for roofing. It is commonly used as a reinforcement material for roofing systems due to its high strength and durability. It helps to enhance the structural integrity of the roof and improve its resistance to weathering and other external factors.

- Q:Is fiberglass mat tissue suitable for agricultural applications?

- Yes, fiberglass mat tissue can be suitable for agricultural applications. It is commonly used in the agricultural industry for various purposes such as reinforcement for greenhouse structures, insulation for livestock housing, and even as a material for composting systems. Its durability, strength, and resistance to weathering make it a viable option for agricultural use.

- Q:How is fiberglass mat tissue used in the production of windshields?

- Fiberglass mat tissue is used in the production of windshields as a reinforcement material. It is sandwiched between layers of glass to increase the strength and durability of the windshield. This tissue provides added resistance to impacts, helps prevent cracks from spreading, and improves overall structural integrity.

- Q:What are the different color options available for fiberglass mat tissue?

- Fiberglass mat tissue is available in various color options to suit different preferences and applications. Some of the common colors available include white, gray, black, and beige. These color options allow for versatility in design and aesthetics, enabling users to choose a color that complements their specific project requirements. The choice of color can also be influenced by factors such as UV resistance and the desired level of visibility or camouflage. Ultimately, the availability of different color options for fiberglass mat tissue provides users with flexibility and customization possibilities to achieve their desired outcome.

- Q:Is fiberglass mat tissue resistant to mildew and rot?

- Indeed, the resistance of fiberglass mat tissue to mildew and rot is undeniable. Crafted from delicate glass fibers interlaced to form a robust and enduring substance, fiberglass stands as a paragon. Its non-porous nature prevents moisture absorption, thus endowing fiberglass mat tissue with exceptional resistance against mildew proliferation and rot-induced decomposition. Moreover, fiberglass often receives protective coatings or additives that amplify its fortitude against these biological detriments. For this reason, fiberglass mat tissue emerges as an exemplary selection in settings where humidity or moisture pose a threat, such as bathrooms, outdoor structures, or regions prone to elevated humidity levels.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

fiber glass wool blanket, glass wool price, fiber glass wool insulation

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords