Heat/thermal insulation Rock Wool Fireproof board

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Glass Wool Blanket:

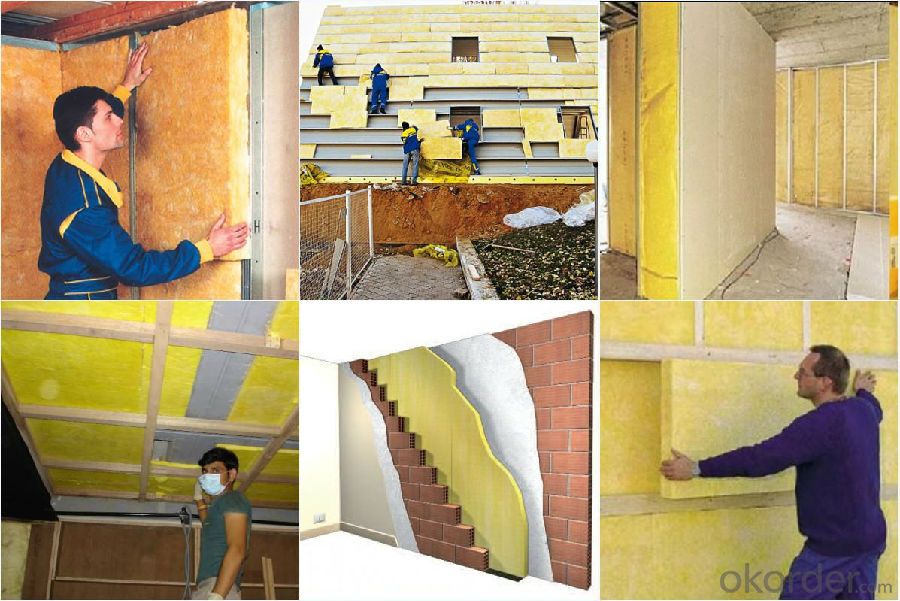

Rock wool insulation board is based on superior melted basalt and diabase as the main raw material, through advanced centrifuge system of four-roller cotton process which pulls melted basaltic rockwool into a 4 ~ 7μm non continuous fibers followed by adding a certain amount of binder, dust laying oil, water repellent before settlement folding, curing, cutting and other processes, and then made into the products of different density depending on purpose of usage.

At the system HOT END, the raw materials are dosed, mixed, melted, fiberized, impregnated with a special binder and formed into a primitive mat of very fine fiber glass. Continuous conveyors transport the mat to the COLD END of the plant for binder polymerization. The product is then cut to shape and packed for shipping.

2.Main features of Glass Wool Blanket:

1. Excellent thermal insulation

2. Fireproof

3. Good sound absorption property

4. Stable and durable.

5. High acidity coefficient

3.Glass Wool Blanket Images:

4. Glass Wool Insulation Blanket Technical Parameters:

Property | High/low temperature resistance, oil and fuel resistance, weathering resistance, O zone resistance etc. |

Shape | According to your requirement. |

Color | Any color is available ,according to your requirements. |

Material | NBR, CR, SBR, EPDM, IIR, NR, EP, Silicone, VITON etc. |

Hardness | 30-90ShoreA |

Delivery | In 10 days |

Packing | Plastic bag & carton box or according to your requirements. |

Application | Electronic field, industrial machine & equipment, house-hold appliance, telecommunication, automobile, medical equipment industry etc. |

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Glass Wool Blanket is one of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q:Can fiberglass mat tissue be used for waterproofing?

- Indeed, fiberglass mat tissue has the potential to be utilized for waterproofing purposes. This particular material, comprised of fiberglass fibers, takes the form of a thin, non-woven substance. Its primary function lies in the reinforcement and provision of waterproofing attributes within the realm of construction and building applications. When combined with a waterproofing agent or resin, the fiberglass mat tissue can establish an impermeable barrier, effectively impeding the infiltration of water or moisture. Consequently, it proves to be a highly advantageous option for various undertakings such as roofing, basement waterproofing, and the installation of bathrooms or showers. Furthermore, the robustness and enduring nature of fiberglass mat tissue contribute to its resistance against cracks or tears, guaranteeing the longevity of its waterproofing capabilities.

- Q:Can fiberglass mat tissue be used in marine applications?

- Yes, fiberglass mat tissue can be used in marine applications. Fiberglass mat tissue is a lightweight and flexible material that is commonly used in boat building and repair. It provides excellent strength and durability, making it suitable for marine environments where the material is exposed to water, salt, and other harsh conditions. Fiberglass mat tissue is often used as a reinforcement layer in the construction of boat hulls, decks, and other structural components. It helps to add strength and stiffness to the composite materials used in marine applications, enhancing their overall performance and longevity. Additionally, fiberglass mat tissue is resistant to corrosion and has good water resistance properties, making it well-suited for marine applications.

- Q:Is fiberglass mat tissue resistant to oil and grease?

- Yes, fiberglass mat tissue is resistant to oil and grease.

- Q:Is fiberglass mat tissue resistant to moisture?

- Fiberglass mat tissue, indeed, exhibits resistance to moisture. By tightly weaving strands of glass fibers and subsequently bonding them with a resin, this tissue fabricates a barrier that effectively thwarts the infiltration of moisture. Consequently, the moisture-resistant properties of fiberglass mat tissue render it exceptionally suitable for deployment in scenarios where water exposure or high humidity is anticipated. Moreover, this tissue's resistance to moisture aids in averting the proliferation of mold or mildew, thereby establishing it as an appropriate selection for environments prone to dampness.

- Q:Is fiberglass mat tissue suitable for insulation in food processing facilities?

- Fiberglass mat tissue is not suitable for insulation in food processing facilities. This material is typically used as a reinforcement in composites, such as roofing and construction materials, and is not designed to meet the specific requirements of food processing environments. Food processing facilities require insulation materials that are safe, durable, and compliant with strict health and safety regulations. Fiberglass mat tissue does not possess these characteristics and may pose potential risks to food safety. Instead, it is recommended to use insulation materials specifically designed for food processing facilities. These materials should be non-toxic, resistant to moisture, mold, and bacteria, and should be able to withstand high temperatures and frequent cleaning and sanitization procedures. Examples of suitable insulation materials for food processing facilities include closed-cell foam, mineral wool, and polyisocyanurate (PIR) foam. These materials have been extensively tested and proven to meet the necessary standards and regulations for use in food processing environments. It is crucial to prioritize the safety and hygiene of food processing facilities, and therefore, it is advisable to consult with experts or insulation specialists who can provide guidance on the most suitable and compliant insulation options for such facilities.

- Q:What are the different types of fiberglass mat tissue available?

- There are several different types of fiberglass mat tissues available, each with its own unique characteristics and applications. Some of the most common types include: 1. Chopped Strand Mat (CSM): This is the most basic and widely used type of fiberglass mat tissue. It consists of randomly oriented chopped strands of fiberglass held together with a binder. CSM is typically used in applications where strength and resilience are important, such as boat building and automotive parts manufacturing. 2. Continuous Filament Mat (CFM): Unlike CSM, CFM is made from continuous strands of fiberglass that are woven into a mat. This type of fiberglass mat tissue offers excellent tensile strength and dimensional stability, making it ideal for applications that require high strength and stiffness, such as aerospace components and wind turbine blades. 3. Surface Veil Mat: Surface veil mat is a very thin and lightweight type of fiberglass mat tissue that is used primarily for surface finishing and reinforcement. It is typically applied as a final layer in composite laminates to improve the surface smoothness and water resistance. 4. Stitched Mat: Stitched mat is made by interweaving continuous strands of fiberglass with a stitching thread. This construction provides increased strength and improved drapability, making it easier to conform to complex shapes. Stitched mat is commonly used in applications that require a combination of strength and flexibility, such as in the production of pipes and tanks. 5. Binderless Mat: Binderless mat is a specialty type of fiberglass mat tissue that does not contain any binders or resins. Instead, the fibers are mechanically bonded together using a needling process. This makes binderless mat highly resistant to chemical attack and suitable for use in corrosive environments, such as chemical storage tanks and pipes. These are just a few examples of the different types of fiberglass mat tissues available. The choice of which type to use depends on the specific requirements of the application, including strength, flexibility, surface finish, and resistance to various environmental factors.

- Q:Can fiberglass mat tissue be used for reinforcing fiberglass boats?

- Reinforcing fiberglass boats is possible with the utilization of fiberglass mat tissue. This material, composed of randomly arranged fiberglass strands held together by a binder, is lightweight, flexible, and easy to work with, making it an excellent choice for this purpose. To create a strong and durable composite material, fiberglass mat tissue is typically combined with fiberglass resin in boat construction. The mat tissue is laid down and infused with resin, which then undergoes curing and hardening to establish a rigid structure. This process effectively enhances the boat's strength, stiffness, and resistance to impact. Fiberglass mat tissue is commonly applied in areas of the boat that require additional reinforcement, such as the hull, deck, or other high-stress regions. By distributing and absorbing forces, it reduces the likelihood of cracking or failure. Moreover, it provides additional protection against impacts and abrasions, thereby extending the lifespan of the boat. Nevertheless, it is important to recognize that fiberglass mat tissue alone may not suffice for reinforcing fiberglass boats. It is often utilized in combination with other reinforcement materials, like fiberglass cloth or woven roving, to create a well-balanced and optimized reinforcement system. Ultimately, the utilization of fiberglass mat tissue for reinforcing fiberglass boats significantly enhances their structural integrity and durability. It is a versatile and cost-effective option that is widely employed in the boat building industry.

- Q:What is the shelf life of fiberglass mat tissue?

- The shelf life of fiberglass mat tissue varies depending on the manufacturer and storage conditions. However, on average, fiberglass mat tissue can have a shelf life of up to 1-2 years if stored properly in a cool, dry place and protected from moisture and direct sunlight. It is important to check the manufacturer's recommendations for specific shelf life information.

- Q:How thick is fiberglass mat tissue typically?

- Fiberglass mat tissue typically has a thickness ranging from 0.3 to 0.6 millimeters.

- Q:Is fiberglass mat tissue suitable for automotive applications?

- Fiberglass mat tissue is indeed suitable for automotive applications. This versatile material offers numerous benefits when utilized in the automotive industry. It boasts excellent strength and durability, crucial qualities for automotive parts that must endure harsh conditions and heavy use. Moreover, fiberglass mat tissue possesses commendable thermal and electrical insulation properties, making it ideal for applications that require resistance to temperature and electrical currents. Furthermore, the lightweight nature of fiberglass mat tissue can contribute to enhanced fuel efficiency and overall vehicle performance. It is also highly malleable, enabling manufacturers to craft intricate automotive parts with precision. Additionally, this material resists corrosion, chemicals, and UV radiation, ensuring that automotive components remain reliable and long-lasting. In summary, the exceptional qualities of fiberglass mat tissue make it an optimal choice for various automotive applications, such as body panels, interior components, structural reinforcements, and sound insulation. Its strength, durability, insulation properties, lightweight nature, and resistance to corrosion and chemicals make it a dependable and cost-effective material for the automotive industry.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Heat/thermal insulation Rock Wool Fireproof board

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords