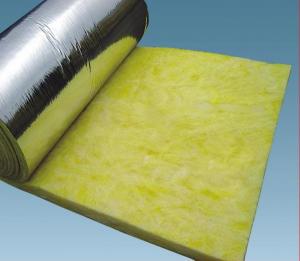

Glass Wool Blanket FSK Faced

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1*40HQ pc

- Supply Capability:

- 100000 Pieces Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Specification of Glass Wool Blanket

Glasswool board is a plate product with fixed strength after hot-setting the centrifugal glass wool. It has excellent thermal insurance performance at both high and low temperature environment.

Item | Unit | Index |

Density | Kg/m3 | 24-96 |

Thickness | mm | 20-100 |

Width | mm | 600-1 200 |

Length | mm | 1 200,2 400 |

Special product with special specification can be made to order.

Unfaced and faced felts are both provided

2. Application of Glass Wool Blanket

It is mainly used for the separating wall in the high-grade building, ceiling, air conduit or inner wall of bellows for thermal insurance, or machine shops for noise absorption, or metal ceiling for control of moisture. High density panels with laminated facing can be used for Air-Conditioning Duct System.

3.Package of Glass Wool Blanket

Normal packing: Each roll is wrapped with vacuum plastic bag, and then in PE woven bag.

Special required package like PE BAG and PE SHRINKED BAG can be made with additional charge.

- Q:Which is the more commonly used thermal insulation material between thermal insulation glass?silk wool and rock wool?

- Glass wool: Glass wool has no shots, having less dust and little irritation to skin and respiratory system as well as light weight, able to be processed to products with long length based on design requirements. It entails less waste, easy to construction. It uses amorphous cellulose which is soft and lathy with no shots, able to serve for more than 20 years. So, in terms of price per ton, rock wool is cheaper than glass wool. But in terms of price per square meter, the prices of glass wool and rock wool are basically flat. If various factors like effect, construciton, service life, safety and bearing structure are took into account comprehensively, glass wool then is more economical. Rock wool: It contains a high content of shots and much dust. It is high irritable to skin and respiratory system, keeping heavy weight, so it cannot be processed for a long time. It entails much waste, difficult to construction. It uses crystalline fiber, which has a high content of shots, is shoyt and unstable. If used for a certain time, its shots and short?fiber will sink, making it unable to maintain a uniform shape, which will seriously affect the insulation effect and needs to be replaced consequently. And the replacement cycle is shorter than 10 years.

- Q:What's the performance and difference of rock wool and glass wool fireproofing material?

- Rock wool and glass wool belong to Class A fireproofing rating, secondly, rock wool can endure high temperature of 800 degrees, glass wool high temperature of 450 degrees, again,unit weight of rock wool is relatively heavier and unit weight of glass wool is lighter, finally, glass wool has better waterproof performance.

- Q:Is centrifugal glass wool or rubber and plastic insualtion board better for air-conditioning air duct insualtion?

- Glass wool is cheaper. Feel free to ask me more. the answer is provided by the Hebei Chengxin Chemical Building. Welcomed the consultation, if satisfied please adopt. Use rubber and plastic more.

- Q:What is the uses of aluminum foil glass wool felt?

- Glass wool serves as four fuctions to paste aluminum foil paper. Insulation, moistureproof, radiation protection, as well as decorative! Glass wool roll mat selection is based on three aspects. One: Dimensions, thickness of]glass wool roll mat of 50 mm, 75 mm, 80 mm, 90 mm, 100 mm, 120 mm. . Finally, it can be made as long as 200mm.

- Q:What is the density of high-temperature glass fiber

- Glass fiber cotton density is only 1/5 that of water. It is absolute hydrophobic, high temperature resistant with high tensile strength. Glass fiber insulation cotton has low thermal conductivity, good sound absorption, long fiber length, high tensile strength. it is widely used in building air conditioning insulation,decorative wall insulation, ceiling decoration, as well as chemical, electric power industry equipment insulation.

- Q:Is hyperfine glass fiber cotton different from the centrifugal glass wool?

- Fine glass fiber cotton is an excellent inorganic non-metallic materials and it has a wide range of varieties. The advantages of it are good insulation, heat resistance, corrosion resistance, high mechanical strength, but the drawback is brittleness and wear resistance.It is made of glass ball or abandoned glass and goes though process of high temperature melting, drawing, winding and weaving. The diameter of the monofilaments is from several microns to twenty microns, equivalent to 1 / 20-1 / 5 of a human hair and each bundle of fiber strands is composed of hundreds or even thousands of monofilament.Glass fibers are commonly used as reinforcing materials, electrical insulating materials, insulation materials and circuit boards in the field of composite materials.Centrifugal glass wool is a silk material which is made by blowing the molten glass by centrifugal blowing processes and spraying thermoset resin. After thermal curing and deep processing, the silk material can be into products with a variety of usages.Centrifugal glass wool is a typical porous sound-absorbing material with fluffy fiber staggering inside and a lot of tiny pores existing.

- Q:Are there any differences between rubber and plastic thermal insulation materials and glass wool thermal insulation materials? Which one is better, please tell me more about it.

- Rubber and plastic materials have advantages of fire resistance, low temperature resistance, and good thermal insulation performance. Glass wool materials have a good thermostability. Generally speaking, rubber and plastic materials are often used for antifreeze pipe insulation, while glass wool materials are used for heating pipe insulation. Rubber and plastic materials are much more expensive than glass.

- Q:How about the sound insulation performance of glass wool felts?

- Fix the glass wool in the wall with pegs, then cover it with plywood, after laying up with wooden surface, nail the wood again.

- Q:How many types of centrifugal glass wool?

- Glass wool belongs to a category of glass fibers, and it is a man-made mineral fibers. Glass wool is melten glass fibrosis, cotton-like material, and the chemical composition is metallic glass type, and is a inorganic fiber having good shape, bulk density, low thermal conductivity and thermal insulation and heat insulation, sound-absorbing properties, corrosion resistance and chemical stability.

- Q:Who know the construction technology of glass wool?

- 1, The construction condition. 1.1, The substrate must be dry and be passed acceptance inspection. 1.2, The construction site should be granted with no more than five grade of wind force during construction. 1.3, Effective measures should be taken during construction in rainy days to prevent glass wool from being wetted by rainwater. 2, the main construction tools: wllpaper knife, electric screwdriver and fe, electric screwdriver and 2m guiding rule. 3, Construction process. 4. Construction points. 4.1, Construction preparation: 4.1.1, Material preparation: Prepare the detailed supply planned order of materials according to the drawings and projects condition. All materials approved into the site must be qualified products, complying with the relevant regulatory requirements nationally, industrially and locally. 4.1.2 Construction machinery: All machinery must be tested to ensure their good performance. 4.1.3, Personnel preparation: Technical personnel must be provided with technical training and technical disclosure. 4.1.4, Technical preparation: It needs to know well the drawings, prepare the relevant portfolios and quality acceptance criteria. 4.2 Installation of glass wool. 4.2.1 Select expansion insulation nails with corresponding length according to the thickness of glass wool, and make glass wool into sample plate based on the field condition before installing it. 4.2.3, Using insulation nails screw to pierce glass wool to install them into the wall according to the position of insulation nails on the facade of wall, which requires that glass wool should be assembled tightly and neatly without folds. 4.2.4, All seams should be cling to with each other with the gap of no more 3mm, and finally all seams should be sealed with adhesive tape.

1. Manufacturer Overview |

|

|---|---|

| Location | Hebei,China |

| Year Established | 1999 |

| Annual Output Value | Above US$50 Million |

| Main Markets | Mid East;Southeast Asia;African |

| Company Certifications | ISO 9001:2008; |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Xingang; |

| Export Percentage | 30% |

| No.of Employees in Trade Department | 20 People |

| Language Spoken: | English;Chinese |

| b)Factory Information | |

| Factory Size: | Above 1000,000 square meters |

| No. of Production Lines | Above 6 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Glass Wool Blanket FSK Faced

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1*40HQ pc

- Supply Capability:

- 100000 Pieces Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords