glass wool heat insulation, sound proof and fireproof material

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Glass Wool Blanket:

Glass wool sention pipe is a kind of economical insulating material which is light and easy to install. This material has excellent performance of heat and sound insulation under both extremely high and low temperature conditions. Therefore, ventilating ducts, industrial civial heat suppling and all kinds of heating, cooling pipelines.

Glass wool, which belongs to glass fiber , is a kind of man-made inorganic fiber. It is made from fibrosis glass melt in wool shape, which belongs to inorganic fiber and fiber in its chemical ingredient. Its merit is better in shape, low density and volume, low in thermal conduction, better heat preservation and thermal insulation, fine sound absorption, corrosion-resistant and stable chemical property.

2.Main features of Glass Wool Blanket:

1) Heat insulation and heat preservation, sound adsorption and noise reduction

2) Low slag indusion content, thin and long inner fiber

3) Thermal stability, stable and high efficiency for a long time

4) High temperature heat-stability, durability, high temperature shrinkage resistance

5) Damp proof property, with the hydrophobicity are not less than 98%

6) Excellent fire proof performance, European standard non-flammable class A material

7) Non-poison, not contain rock wool and doesn't grow the mould etc.

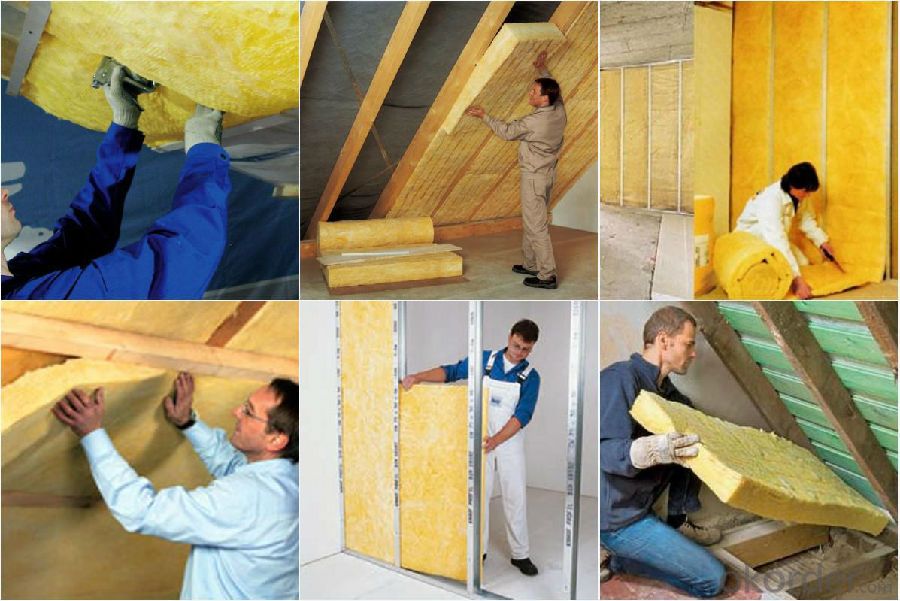

3.Glass Wool Blanket Images:

4. Glass Wool Insulation Blanket Technical Parameters:

Property | High/low temperature resistance, oil and fuel resistance, weathering resistance, O zone resistance etc. |

Shape | According to your requirement. |

Color | Any color is available ,according to your requirements. |

Material | NBR, CR, SBR, EPDM, IIR, NR, EP, Silicone, VITON etc. |

Hardness | 30-90ShoreA |

Delivery | In 10 days |

Packing | Plastic bag & carton box or according to your requirements. |

Application | Electronic field, industrial machine & equipment, house-hold appliance, telecommunication, automobile, medical equipment industry etc. |

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Glass Wool Blanket is one of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q:Is the Teflon gasket filled with fiberglass or graphite?

- PTFE itself has the effect of self lubrication, you can ask the production of PTFE can add these, should not be able to! Vespel can add graphite to increase self lubrication

- Q:What are the properties of fiberglass mat tissue?

- Fiberglass mat tissue, also known as fiberglass mat or fiberglass matting, is a type of non-woven material made from glass fibers. It possesses several properties that make it suitable for various applications. 1. Strength and durability: Fiberglass mat tissue is known for its high tensile strength, which means it can withstand significant amounts of stress without breaking. This property makes it ideal for reinforcing and strengthening different materials and structures. 2. Lightweight: Despite its strength, fiberglass mat tissue is relatively lightweight, making it easy to handle and transport. This property is particularly advantageous in industries where weight reduction is important, such as aerospace and automotive. 3. Flexibility: Fiberglass mat tissue is flexible, which allows it to conform to curved surfaces and complex shapes. This property makes it versatile and suitable for applications where the material needs to be molded or formed into specific designs. 4. Chemical resistance: Fiberglass mat tissue has excellent resistance to various chemicals, including acids, alkalis, and most solvents. This property makes it suitable for applications in corrosive environments, such as chemical processing plants or storage tanks. 5. Thermal insulation: Fiberglass mat tissue has good thermal insulation properties, meaning it can help to reduce heat transfer. This property makes it useful in applications where heat insulation is required, such as in the construction of walls, roofs, or insulation boards. 6. Fire resistance: Fiberglass mat tissue is inherently fire-resistant and does not contribute to the spread of flames. This property makes it widely used in applications where fire safety is essential, such as in the production of fire-resistant doors, panels, or insulation materials. 7. Sound insulation: Fiberglass mat tissue also offers good sound insulation properties, reducing noise transmission through walls or other structures. This property makes it suitable for use in soundproofing applications, such as in recording studios or automotive interior panels. Overall, the properties of fiberglass mat tissue make it a versatile material with a wide range of applications in various industries, including construction, automotive, aerospace, and marine. Its strength, flexibility, lightweight, chemical resistance, thermal and sound insulation properties, as well as its fire resistance, contribute to its popularity and usefulness in many different applications.

- Q:How does fiberglass mat tissue perform in high temperatures?

- Due to its inherent heat resistance properties, fiberglass mat tissue is highly effective in high temperatures. The mat is crafted from woven glass fibers, creating a durable and sturdy material. These glass fibers possess a high melting point, enabling the fiberglass mat tissue to endure elevated temperatures without distorting or compromising its structural integrity. Unlike other materials, fiberglass mat tissue does not shrink, warp, or become brittle when exposed to high temperatures. It maintains its dimensional stability and mechanical strength, making it suitable for a wide range of applications in industries such as automotive, aerospace, construction, and insulation. Furthermore, fiberglass mat tissue acts as a thermal insulator, providing protection against heat transfer. It effectively resists heat conduction and radiation, assisting in maintaining the desired temperature in a given environment or preventing heat damage to nearby components. Moreover, fiberglass mat tissue is non-combustible, meaning it does not burn or release toxic gases when subjected to fire. This characteristic makes it a dependable choice for applications that necessitate fire resistance, such as fireproofing insulation or protective barriers. In conclusion, fiberglass mat tissue excels in high temperatures. Its heat resistance, dimensional stability, mechanical strength, thermal insulation properties, and non-combustible nature establish it as an outstanding material for demanding environments where elevated temperatures are present.

- Q:What is the UV resistance of fiberglass mat tissue?

- The UV resistance of fiberglass mat tissue is high due to the inherent properties of fiberglass, making it a suitable choice for outdoor applications where exposure to sunlight is a concern.

- Q:What is the expected lifespan of fiberglass mat tissue in outdoor applications?

- The expected lifespan of fiberglass mat tissue in outdoor applications can vary depending on various factors such as exposure to weather conditions, maintenance, and quality of the material. However, on average, fiberglass mat tissue is designed to have a lifespan of around 20 to 30 years in outdoor applications. Fiberglass mat tissue is commonly used for reinforcing and providing strength to surfaces in outdoor applications such as roofing, construction, and automotive industries. It is known for its durability, resistance to moisture, and ability to withstand harsh weather conditions. To ensure a longer lifespan for fiberglass mat tissue in outdoor applications, it is crucial to properly maintain and protect it. Regular inspections, cleaning, and repairs when necessary can help prevent any potential damage or deterioration. Additionally, applying protective coatings or sealants can further enhance its resistance to UV rays, moisture, and other environmental factors. It's important to note that the lifespan of fiberglass mat tissue can vary depending on the specific application and the quality of the material used. Therefore, it is recommended to consult with the manufacturer or a professional in the industry to determine the expected lifespan for a specific project or application.

- Q:Can fiberglass mat tissue be used for repairing fiberglass bathtubs?

- Yes, fiberglass mat tissue can be used for repairing fiberglass bathtubs. It is commonly used as a reinforcement material in fiberglass repairs, providing added strength and durability to the repaired area. The tissue can be easily applied and works well for repairing cracks, chips, or other damage on fiberglass bathtubs.

- Q:What are the recommended storage and handling practices for fiberglass mat tissue?

- When it comes to the storage and handling of fiberglass mat tissue, there are a few recommended practices that should be followed to ensure its integrity and longevity. 1. Storage: It is important to store fiberglass mat tissue in a clean and dry environment. This helps prevent any moisture or dirt from damaging the material. Ideally, it should be stored indoors away from direct sunlight and extreme temperatures. 2. Handling: Fiberglass mat tissue is a delicate material that can be easily damaged if not handled properly. It is recommended to wear protective gloves and safety glasses when handling it to prevent any injuries. Additionally, it should be handled with care to avoid any tears or creases that may compromise its performance. 3. Transportation: During transportation, it is crucial to pack fiberglass mat tissue in a way that minimizes the risk of damage. It should be securely packaged and protected from any potential impact or vibration. If possible, it is best to transport it in a dedicated vehicle or container to ensure its safety. 4. Avoid contact with chemicals: Fiberglass mat tissue should not come into contact with chemicals such as acids, alkalis, or solvents. These substances can cause degradation and weaken the material. It is important to handle it with clean hands and avoid any contact with substances that may be harmful. 5. Follow manufacturer's guidelines: It is always advisable to follow the specific recommendations provided by the manufacturer regarding the storage and handling of fiberglass mat tissue. Different manufacturers may have slightly different requirements, and it is important to adhere to them for optimal performance and longevity. By following these recommended storage and handling practices, you can ensure that fiberglass mat tissue remains in good condition, ready for its intended use.

- Q:Does fiberglass mat tissue require any special surface treatments before application?

- Special surface treatments are necessary before applying fiberglass mat tissue in order to ensure proper adhesion and bonding with the substrate. Applying a primer or bonding agent is a common treatment that enhances the bond strength between the fiberglass mat tissue and the substrate. Typically, the primer or bonding agent is applied to the substrate and allowed to dry before applying the fiberglass mat tissue. Another treatment involves removing any loose or flaking material from the substrate's surface. This can be achieved through mechanical methods like sanding or grinding, or by using a chemical treatment to dissolve or eliminate unwanted material. This step is crucial to establish a clean and smooth surface for the fiberglass mat tissue to adhere to. In certain cases, it may be necessary to roughen or etch the substrate's surface to provide a better bonding surface for the fiberglass mat tissue. The method used for roughening or etching depends on the type of substrate being used and can involve abrasives or chemical etching agents. The specific surface treatment required for fiberglass mat tissue depends on factors such as the type of substrate, desired bond strength, and application method. Following the manufacturer's instructions and recommendations for surface preparation is essential to achieve a successful application and long-lasting bond.

- Q:How is fiberglass mat tissue used in the production of shower enclosures?

- Fiberglass mat tissue is commonly used in the production of shower enclosures due to its excellent properties and benefits. It is a thin and flexible material made up of fine glass fibers that are randomly distributed and bonded together with a resin binder. In the production process of shower enclosures, fiberglass mat tissue is primarily utilized as a reinforcement material. It is often applied to the surface of the enclosure structure to enhance its strength, durability, and resistance to cracking or breaking. Firstly, the fiberglass mat tissue is cut and sized to fit the specific dimensions of the shower enclosure. It is then carefully laid or applied onto the surface of the enclosure, usually through a process called hand lay-up or spray-up. The mat tissue is positioned strategically to cover all the critical areas that require reinforcement, such as corners, edges, and joints. Once the mat tissue is in place, a resin, typically polyester or epoxy, is applied over it. The resin infiltrates the fiberglass mat tissue and bonds with the fibers, creating a solid and robust composite structure. This resin-fiberglass combination provides additional strength and stability to the shower enclosure, making it more resistant to impact, stress, and environmental factors like water and humidity. Moreover, fiberglass mat tissue also contributes to the overall aesthetics of the shower enclosure. It can help create a smooth and uniform surface finish, eliminating imperfections and creating a visually appealing appearance. The mat tissue can be easily molded or shaped to match different designs and styles, enabling manufacturers to produce shower enclosures with various shapes, sizes, and patterns. In summary, fiberglass mat tissue plays a crucial role in the production of shower enclosures by providing reinforcement, strength, durability, and aesthetic benefits. It is a versatile material that enhances the overall performance and visual appeal of the enclosures, ensuring they can withstand daily use and maintain their quality over time.

- Q:Is fiberglass mat tissue suitable for architectural applications?

- Yes, fiberglass mat tissue is suitable for architectural applications. Fiberglass mat tissue is a lightweight and flexible material that is commonly used in construction and architectural projects. It has excellent strength and durability, making it suitable for various architectural applications such as wall cladding, roofing, insulation, and decorative panels. Additionally, fiberglass mat tissue is resistant to water, chemicals, and fire, which further enhances its suitability for architectural use. Its versatility allows it to be easily molded into different shapes and sizes, providing architects with great design flexibility. Overall, fiberglass mat tissue is a reliable and effective material that can be successfully utilized in architectural applications.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

glass wool heat insulation, sound proof and fireproof material

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords