Graphite Electrode with Nipple with Good Quality

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Graphite Electrode

Graphite electrode is made from the domestic first petroleum coke and high quality needle coke

and widely used in the electric arc furnaces for production of alloy steels, metal and other

nonmetallic materials, etc. The graphite electrodes include regular power, high power, super high power, ultra high power and square electrode. The range of diameters covers from 200mm to

700mm. Our products own the following characteristics: low electric resistance, good electric and

thermal conductivity, high oxidation resistance, greater resistance to thermal and mechanical shock, high mechanical strength, high machining accuracy.

Product Applications:

It is used for the electric arc furnace steel making. (About 70-80% graphite electrode is used for steel making).

It is used for the submerged arc furnace, including melting iron alloy, pure silicon, yellow

phosphorus,matte, calcium carbide and so on.

It is used for the resistance furnace, such as the graphite making, melting glass, silicon carbide

making and so on.

Product Advantages:

28 drums counter-flow calcining furnace

Auto-control dosing system

Germany Enrich kneading system

3500MT vertical tamping&horizontal extruding press

Auto-comtrol ring backing furnace

Germany Feist-incon 2nd Baking Kiln

High pressure imprgnation system

Acheson high power DC graphitizing furnace

Japan Nachi NC electrode machining line

America lngersoll NC electrode machine line

Japan Nachi NC nipple machining line

Carbon fiber production line

Main Product Features:

Good electrical conductivity

High resistance to thermal shock

High mechanical strength

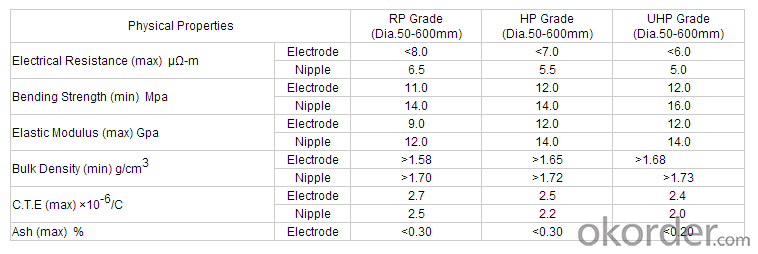

Product Specifications:

FAQ:

1. How you can control your quality?

For each production processing, we have complete QC system for the chemical composition

and Physical properties. After production, all the goods will be tested, and the quality certificate

will be shipped along with goods.

2. What's your delivery time?

It usually needs about 20days- 45 days after receiving the deposit.

3. Do you provide free samples?

Yes, we can provide a free sample for testing, If we have sample in stock,

The quantity based on the material type, The buyer should bear all the shipping costs.

4. What's your payment terms?

We can accept 30% deposit, 70% balance before shipment for ordrs over $ 2000.

5. Can we visit your Company?

Yes, certainly. You are very welcome to China and we will be honored to have a customer and friend.

6. What standards do we have?

Our products meet the standards, such as ASTM, ASME, AMS, DIN, JIS etc.

The third party testing is all available for us.

Product Picture

- Q:What is the reason that the current cannot be increased when the graphite electrode is used for anode electrolysis?Add calcium chloride and sodium bicarbonate into electrolytic water

- The reason is that the resistance increases continuously, the number of ions is limited, and the conductivity is limited

- Q:Does the silicon carbide heat plant require a fine structure graphite electrode? What kind of graphite products do you need?

- But because the silicon carbide is too hard, it is difficult to machining, good workability, such as non special requirements, using graphite instead of silicon carbide, instead of the effect is not good, but can use a silicon carbide, easy processing, small life than silicon carbide.

- Q:MITSUBISHI machine graphite electrode processing, how does not accumulate carbon?

- The impact of carbon on the car is quite large, first of all, to reduce the power of the engine, that is, to make the power output uneven and gradually attenuated, in other words, more and more lack of force. Two is to increase fuel consumption, increase your financial burden.

- Q:How large is the permissible overload current per square millimeter of the graphite electrode cross section?

- Overhead wires, radiating the best conditions, allowed the current largest. The insulated wire in the house is laid in the wall, which has the worst heat release conditions and the smaller permissible current, so there are different safety currents.

- Q:After vacuum melting of quartz crucible, there are three graphite electrode rods. What's the adjustment?

- Or did you adjust the electrode when it was installed? There are two electrode distance, two away, causing melting after different lengths.

- Q:How should carbon deposits be treated?

- In this way, can keep the engine seal, to prevent oil because the gap is too large and rampant, buried carbon curse generation "".

- Q:Carbon graphite electrode and what is the difference?

- Graphite electrode is a mixture of natural graphite and petroleum coke and asphalt coke. After being treated by high temperature graphitization, the material is composed of graphite;

- Q:The future of graphene

- A report released recently pointed out that the Chinese Academy of Sciences, graphene research and industrialization continues to heat up, from the distribution of graphene patents in the field, including the application of technology research hot spots: layout of graphene as a electrode material of lithium ion batteries, solar battery electrode materials, thin film transistor preparation, sensor, semiconductor device, composite material preparation of transparent, touch screen display, transparent electrode

- Q:Specification for graphite electrodes commonly used in steel works

- The variety and specifications of graphite electrodes used in modern EAF steelmaking are mainly determined by the technical parameters of the steelmaking furnace. With the development of EAF steelmaking technology, the steel-making technology is developing towards large scale and ultra high power. The graphite electrode is mainly made of large size graphite electrode and ultra high power graphite electrode.

- Q:How to solve the problem of graphite electrode being crushed during electrolysis

- I can only use the experience of the past to tell you that if you want to save money easily, the time can be considered as the costA thick graphite stick; inexpensive

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Graphite Electrode with Nipple with Good Quality

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords