High Temperature Insulation Fiberglass Needle Mats

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description: Our high-quality Glass Fiber Mat is made by means of needle punching process with the mixed silicic acid glass fiber, that is chopped from long glass fiber. It is fire retardant, high temperatures resistant, good chemical and abrasion resistant, electrically and acoustically insulating and so on. The main applications are soundproof, heat resistant, heat protection, thermal insulation on pipes, insulator for high temperatures, or other industrial areas.

Features: high temperature, chemical, and abrasion resistance, fire retardant

Application: Fiberglass Mesh Cloth, resistant high temperatures

PRICE: USD2 per kilogram

UNIT: Kilogram

MOQ: 100 KGS

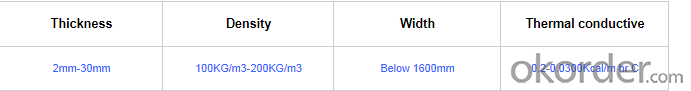

Width: 1m,1.2m,1.5m or customized

Yarn Type: E-glass

Standing temperature: up to 650℃

Product name: E Glass Needle Mat

Roll length: 50 meter or customized

Color: white

Weave Type:conventional

Alkali content: Alkali free

Processing service: cutting

Material: fiberglass

Thickness: 20mm or customized

Size: can be customized

Supply ability: 200000 Kilogram/Kilograms per Month

Packaging: Rolls packed In cartons loaded on pallets or according to customers' requirements.

Lead time: 7-30 days

Technology: nonwoven, laminating and needle-punched

- Q:What are the different surface textures available in fiberglass fabric?

- Fiberglass fabric is known for its versatility and wide range of surface textures, each offering unique properties and benefits. Some of the different surface textures available in fiberglass fabric include: 1. Plain Weave: This is the most basic and commonly used texture, featuring a simple over-and-under pattern of fibers. It offers good strength and stability while providing a smooth surface finish. 2. Twill Weave: Twill weave consists of a diagonal pattern created by interlacing fibers. It offers improved drapability, better conformability, and increased strength compared to plain weave. Twill weave also provides a distinctive appearance. 3. Satin Weave: Satin weave involves floating yarns over multiple warp or weft yarns, resulting in a smooth and lustrous surface. It offers excellent flexibility, durability, and a high-quality finish. Satin weave is commonly used in applications requiring a high level of aesthetics. 4. Leno Weave: Leno weave is characterized by a pair of warp yarns twisting around weft yarns, creating an open mesh structure. This texture enhances breathability, allows easy resin saturation, and provides good drapability. Leno weave is often utilized in applications where air circulation or filtration is crucial. 5. Jacquard Weave: Jacquard weave involves complex patterns created by individual control of each warp yarn. It allows intricate designs and textures to be woven into the fabric. Jacquard weave is commonly used for decorative purposes or when specific patterns are required. Each surface texture in fiberglass fabric is designed to cater to specific applications, such as aerospace, automotive, marine, construction, and industrial sectors. The choice of texture depends on factors such as the desired strength, flexibility, aesthetics, and functionality required for the particular application.

- Q:Are fiberglass fabrics suitable for use in the automotive industry?

- Yes, fiberglass fabrics are suitable for use in the automotive industry. They are lightweight, strong, and durable, making them ideal for various applications such as reinforcing body panels, manufacturing interior trim components, and creating structural supports. Fiberglass fabrics also offer resistance to heat, chemicals, and corrosion, making them a reliable choice for automotive applications.

- Q:How is fiberglass fabric used in the packaging industry?

- Fiberglass fabric is commonly used in the packaging industry as a reinforcement material for packaging materials such as boxes, cartons, and crates. Its high strength-to-weight ratio and durability make it an ideal choice for providing structural support and protection to the packaged goods. Additionally, fiberglass fabric can also be used as a heat and moisture barrier, preventing damage caused by temperature variations and humidity during transportation and storage.

- Q:Is fiberglass fabric suitable for making protective clothing?

- Yes, fiberglass fabric is suitable for making protective clothing. It is known for its fire resistance, high strength, and durability, making it an ideal choice for protective gear in industries such as firefighting, welding, and chemical handling. Additionally, fiberglass fabric offers excellent insulation properties and is resistant to chemicals, making it a reliable material for protecting against hazards.

- Q:How is fiberglass fabric coated?

- Fiberglass fabric is typically coated using various techniques such as dip coating, roll coating, or spray coating. These methods involve applying a layer of resin or polymer onto the surface of the fabric to enhance its properties, such as improving its strength, flexibility, and resistance to chemicals or fire. The coated fabric is then dried or cured to ensure the coating adheres properly, resulting in a durable and versatile material.

- Q:Is fiberglass fabric resistant to chemicals in water treatment facilities?

- Yes, fiberglass fabric is generally resistant to chemicals in water treatment facilities. Fiberglass is known for its excellent chemical resistance, meaning it can withstand exposure to various chemicals without deteriorating or losing its structural integrity. This makes it an ideal material for use in water treatment facilities, where chemicals are used for disinfection, pH adjustment, and other treatment processes. Fiberglass fabric can resist the corrosive effects of chlorine, acids, alkalis, and other chemicals commonly found in water treatment facilities. Additionally, fiberglass is non-reactive, meaning it does not interact with or contaminate the water being treated. This makes it a reliable and durable choice for use in water treatment applications.

- Q:What's the function of fiberglass cloth? Where can I use it?

- Use more now is fiberglass duct, glass fiber glass cotton material, is insulation core material composite wind pipe model, generally 2.5 cm thickness, glass fiber materials with fine wool like dust, can not be directly used for ventilation, so both sides of glass fiber insulation core material can be used glass fiber cloth paste, to prevent dust lanose into the duct.

- Q:What is the basis of testing polyester glass fiber cloth?

- Do not use polyester fiber surface will appear crack reflection in a few months, polyester fiber due to the elongation rate and instantaneous tensile strength is very low, can effectively eliminate the road junction or crack stress concentration, reduce the crack in the pavement and reflected upward, can delay the reflecting crack extend the life of the road, thereby greatly reducing the cost of repair and maintenance.

- Q:Is fiberglass fabric resistant to chemicals in wastewater treatment?

- Yes, fiberglass fabric is generally resistant to chemicals in wastewater treatment. It has excellent chemical resistance properties, making it suitable for use in various industrial applications, including wastewater treatment facilities.

- Q:Can fiberglass fabric be used for making curtains or dividers?

- Fiberglass fabric is capable of being utilized in the creation of curtains or dividers. Its reputation lies in its durability, strength, and fire resistance, rendering it an appropriate material for these purposes. Additionally, it possesses a lightweight and flexible nature, facilitating effortless manipulation and installation. Furthermore, fiberglass fabric boasts easy cleaning and maintenance, making it a practical selection for curtains or dividers across diverse settings, including homes, offices, and industrial spaces.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Temperature Insulation Fiberglass Needle Mats

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords