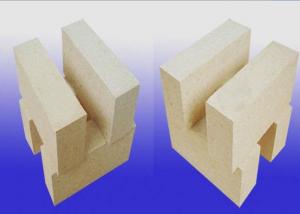

Inner Orange Glass Block

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 9000 Pieces pc

- Supply Capability:

- 1000000 Pieces per Month pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Introduction of Inner Orange Glass Block

1)We have various styles and designs

2)glass block is modernizational,environment-friendly decorative material.

Size(mm) |

Packing (pcs/ctn) |

Dimension (cm) |

Unit weight (kg) | Capacity/20’ | |

Without pallet |

With pallet | ||||

190*190*80mmclear | 6 |

39.5*26*20 | 2.3 |

9000pcs |

7200pcs |

190*190*80mmcolor | 6 |

39.5*26*20 | 2.3 |

9000pcs |

7200pcs |

190*190*95mmclear | 6 |

39.5*30*20.5 | 2.5 |

7500pcs |

4800pcs |

145*145*95mmclear | 8 |

42*30.5*16 | 1.7 |

11200pcs |

8960pcs |

145*145*80mmclear | 10 |

43*30*16 | 1.5 |

12500pcs |

10400pcs |

- Q:Please take a lot of examples, thanks. The Some difficult to understand the best talk about the reasons, huh, huh.

- Structural materials include wood, bamboo, stone, cement, concrete, metal, brick, ceramic, glass, engineering plastics, composite materials, etc

- Q:240 thick mu50 aerated autoclaved fly ash aerated concrete block size

- 240 thick mu50 aerated autoclaved fly ash aerated concrete block size 600 mm * 240 mm * 200 mm

- Q:Project materials into the post-mortem report which need to re-test report qualified, the supervision to sign the use of?

- Five, concrete with a variety of admixture wall materials: all kinds of bricks, blocks and so on Seven, all kinds of waterproof material eight, light aggregate concrete nine, decorative materials ten, building doors and windows to the drainage pipe and pipe fittings all kinds of radiators insulation materials and their products soil and foundation : For the cushion method, pre-pressing method, etc building appliances the use of construction projects indoor environmental pollution control and material inspection reinforced structural engineering: ordinary steel, stainless steel welding, surfacing electrodes, welding balls The

- Q:What are the factors that affect masonry quality in masonry structures?

- In front of someone to answer a very comprehensive, I will look at his top bar Oh!

- Q:What is the specific difference between steam-free foam and autoclaved concrete blocks? What are their strengths and weaknesses? Free foam brick production in the easy problems

- Autoclaved concrete block: from (silica) silica fume, lime and a small amount of cement slurry injection molding, calcium oxide to provide the heat and the appropriate alkalinity under the action of adding aluminum powder gas agent reaction, release H (OH) Al2O3 and Fe2O3 in the raw materials, and the new phase, calcium silicate, aluminosilicate and aluminosilicate were formed by the thickening of the slurry Calcium, calcium aluminate Autoclaved concrete block bulk density is mostly 500-800g / cm compressive strength ≥ 35MPa, can be used as frame structure of the wall material, is the national promotion of new wall materials Autoclaved concrete block investment is relatively large

- Q:What are the block materials used in our masonry works? In recent years, what are the changes in wall materials?

- Sintered bricks include sintered ordinary bricks and sintered porous bricks with materials such as clay, shale, coal gangue and fly ash

- Q:What is the difference between fly ash autoclaved brick and fly ash aerated concrete block

- The production process of fly ash autoclaved brick includes the preparation of raw materials, according to a certain proportion of measuring ingredients, mixing, digestion, wheel grinding, pressing molding, code bus static maintenance, autoclaved curing, finished product inspection and stacking and other major steps. The concept of fly ash concrete is aerated concrete is the silicon material at the edge of the factory at the end of the boarding materials (sand, fly ash and silicon tailings, etc.) and calcium material (lime, cement) The main raw materials, mixed with gas generator (aluminum powder), through the ingredients, mixing, pouring, pre-feeding, cutting, autoclaving, curing and other processes made of lightweight porous silicate products. You detailed consultation under the professional fly ash brick manufacturers, free hotline: four thousand - six thousand units - unitary unit twenty-six

- Q:What is the block of the external wall of the frame structure?

- Are generally inflatable block, light weight, insulation, heat insulation. Can not load. Generally above the gap to stay 30CM

- Q:Aerated Concrete Block Wall Plastering Cracking What is the aerated concrete?

- Practice has proved that, in order to crack, the choice of plaster mortar deformation capacity should be greater than the aerated concrete deformation capacity, its flexibility than aerated concrete, strength and aerated concrete is almost the same; at the same time plaster outside the anti- Crack material and decorative layer of material deformation capacity and flexibility should be strengthened layer by layer, step by step gradient

- Q:Gypsum block do cut off the light wall decoration with how

- Block stacking, should avoid the rain damp, should be stacked in the room

We are one of the biggest productive bases of glass block in China. We have many years manufacturing experience with all kinds of style and colour. Providing excellent quality and competitive price, are enjoying a high reputation all over the world market. Our company specializes in manufacturing a variety of building materials and chemical products.

1. Manufacturer Overview |

|

|---|---|

| Location | Hebei,China (Mainland) |

| Year Established | 1999 |

| Annual Output Value | US$10 Million - US$50 Million |

| Main Markets | North America; South America; Eastern Europe; Southeast Asia; Africa; Mid East; Eastern Asia; Western Europe |

| Company Certifications | ISO 9001:2000;ISO 14001:2004 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | 91% - 100% |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | 30,000-50,000 square meters |

| No. of Production Lines | 3 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | |

Send your message to us

Inner Orange Glass Block

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 9000 Pieces pc

- Supply Capability:

- 1000000 Pieces per Month pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Hot Searches

Related keywords